50

LNG

INDUSTRY

MARCH

2016

compressor. The working fluid can be nitrogen, methane or a

mixture of both. While methane performs better at

precooling and liquefaction stages, nitrogen yields better

efficiency at the subcooling stage, avoiding methane

operating at low pressure. In offshore operations, nitrogen is

preferred as the inert gas is a safer working medium.

The configuration of the expander cycle

2

has been

optimised based on a two-stage expander cycle, as shown in

Figure 3. With the two-stage expander design, the heat

composite curves of the feed gas and the refrigerant can be

closely matched, as shown in Figure 4. Adjusting the flow

and pressure to the inter-stage compressor optimises the

cold section of the process.

The gas expander cycle is robust as it can be operated

with a wide range of feed gas compositions. Operation

requires minimal operator attention, which is important for

remote and offshore operation. The gas phase system can be

started up and shutdown quickly and safely.

LNG production and relative

cost

LNG production rate is primarily dependent on the available

power to the refrigeration compressors. In a standalone SMR

design, the gas turbine driver output determines the LNG

production rate. With the addition of the ORC power, LNG

production can be increased for both the SMR and expander

processes.

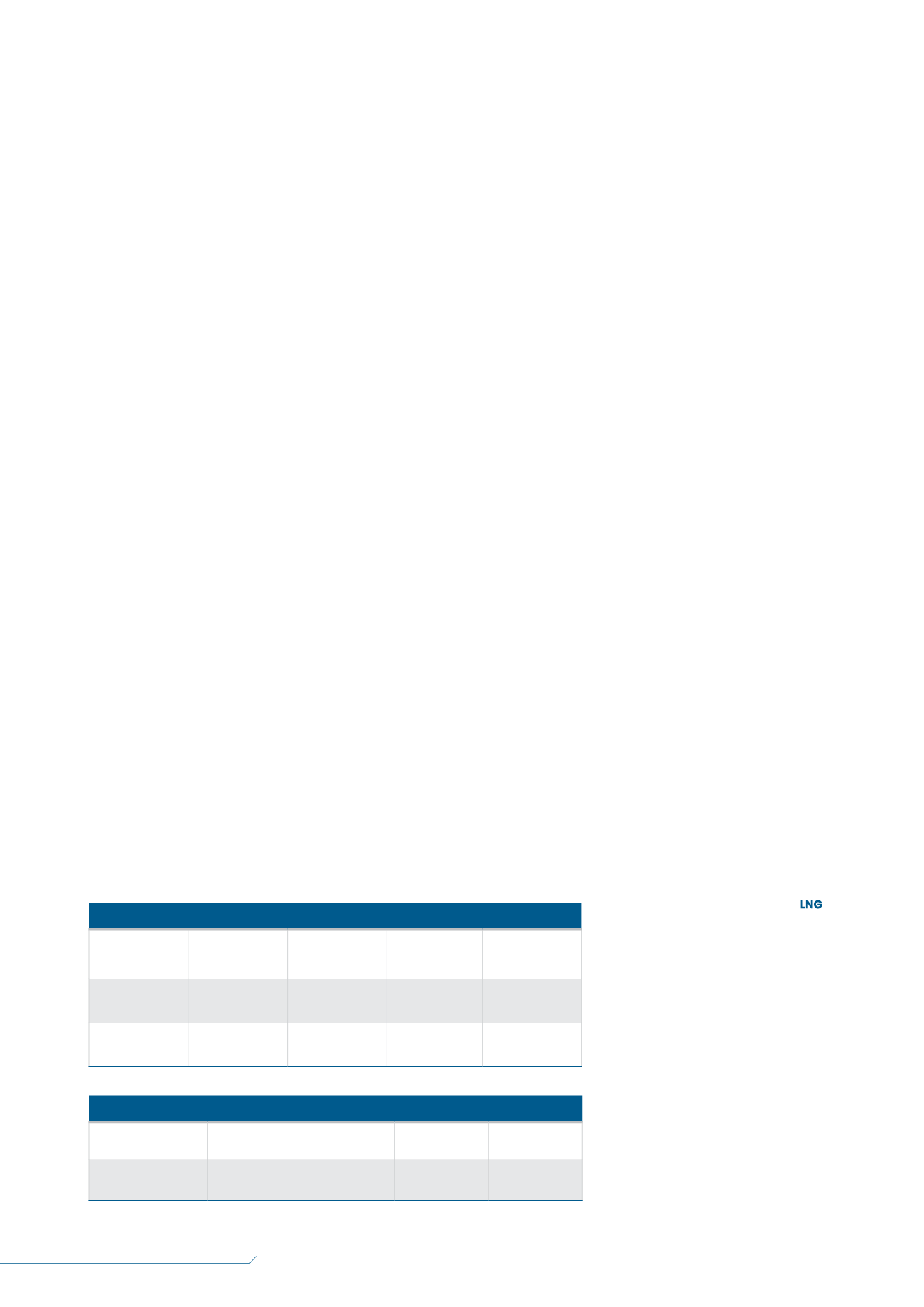

Table 1 summarises the LNG production and the relative

cost for the four design options. The comparison is based on

a typical gas turbine driver with power to produce

1 million tpy of LNG using the standalone SMR process.

For the SMR process, with additional power from the

ORC plant, LNG production can be increased by 35% to

1.35 million tpy. The cost of the ORC plant only adds 10% to

the SMR standalone plant. The incremental cost of the ORC

can be justified with the higher production. When compared

to the gas turbine power plant, the ORC incremental power

cost is significantly lower, mainly due to the process

simplicity, and the use of the low cost carbon steel

equipment.

The LNG production rates with the expander cycle are

more sensitive to ambient temperatures, as less compressor

power is required for cold ambient operation. Rates range

from 0.8 million tpy to 1 million tpy, for an ambient

temperature range from 77°F to 50°F. With the addition of

ORC power, the expander cycle can produce 1 million tpy to

1.2 million tpy of LNG.

The standalone expander cycle plant cost is

approximately 10% higher than the standalone SMR plant

due to the addition of the two expander compressor sets,

and the larger cold box. On the other hand, the refrigeration

compression cost is lower due to the elimination of the

temperature control and two-phase operation. With the

addition of the ORC plant, the overall cost is approximately

20% higher than the standalone SMR design.

Note that the LNG plant cost is based on Inside Battery

Limits (ISBL) equipment only and does not include the cost

for utilities, offsites and storage.

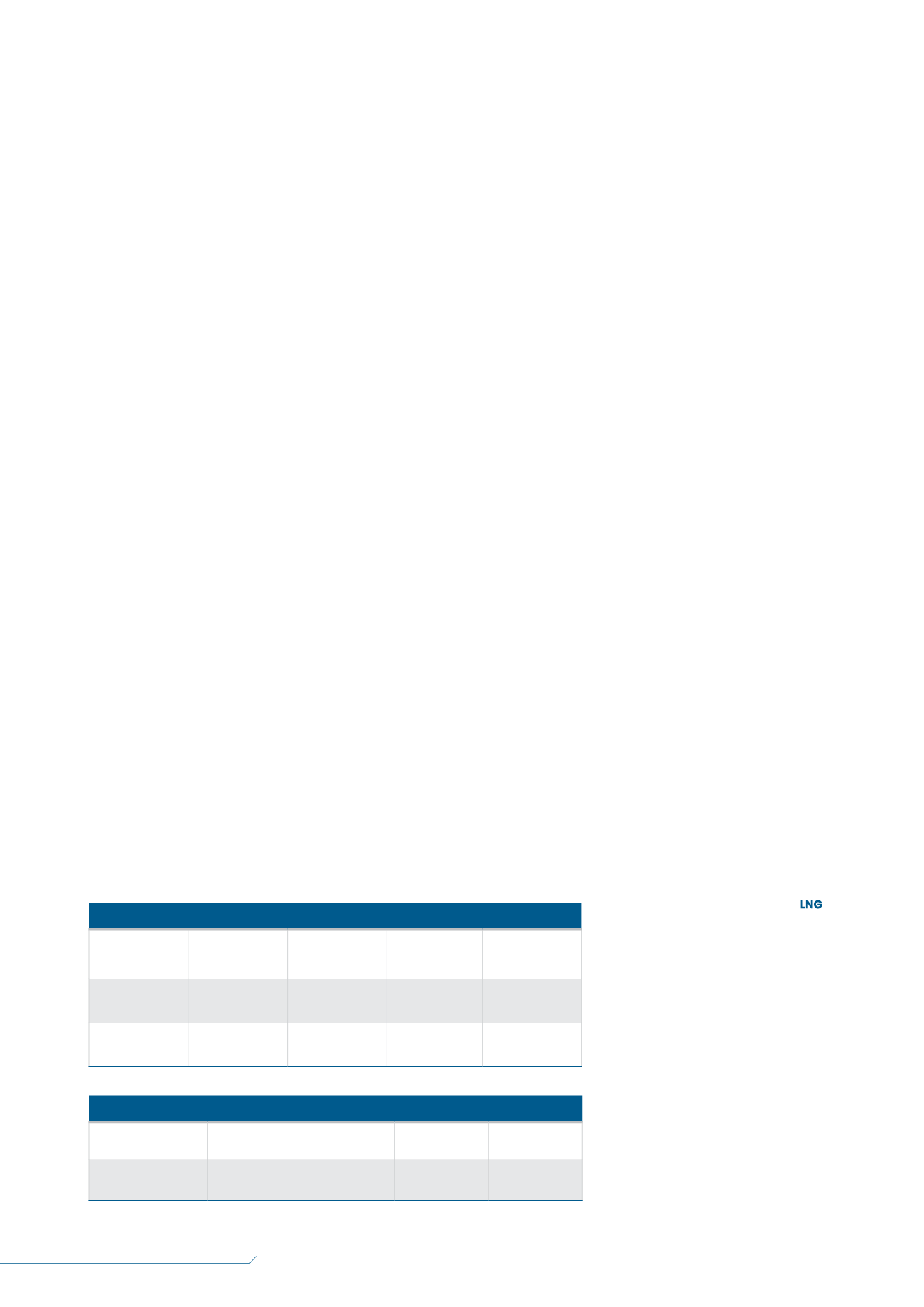

LNG plant specific power

consumption

When power produced from the ORC plant is used to

operate the first stage of the refrigeration compressors,

power consumption by the liquefaction plant is reduced. The

specific power is based on a lean gas with a feed pressure

of 850 psig. The range of specific power consumption for

the four designs is summarised in Table 2. The wider range

for the SMR and expander cycle specific power is due to the

range of ambient temperature from 50°F to 77°F. The power

consumption is reduced per ton of LNG production in cold

climate operation.

Conclusion

The use of the ORC can reduce energy consumption and CO

2

emissions when compared to the standalone liquefaction

process in mid scale LNG plants. The ORC is a proven

process, but is yet to be applied to LNG liquefaction. The

application can provide benefits for both the SMR and the

gas expander cycle that is customised for mid scale LNG

liquefaction plants. In summary, the advantages of the

ORC power integration to LNG liquefaction for mid scale

liquefaction plants include the following:

Lower CAPEX and OPEX cost per unit of LNG liquefied.

Lower refrigerant power consumption per unit of LNG

liquefied, reducing overall carbon footprint.

Higher LNG throughput for a given

refrigeration compressor driver.

References

1. Fluor Patent Application Serial

Number 62125 J 808: ‘Methods

and Configuration for LNG

Liquefaction ORC-SMR Process.’

2. Fluor Patent Application Serial

Number 62/252247: ‘Methods

and Configuration for LNG

Liquefaction ORC-Twin Expander

Process.’

3. ‘Handbook of Natural Gas

Transmission and Processing’,

third edition, (2 March 2015),

Elsevier, Gulf Professional

Publishing.

4. ‘Handbook of Liquefied Natural

Gas,’ first edition, (2014), Elsevier,

Gulf Professional Publishing.

Table 1.

LNG production and relative costs

Liquefaction

process

Standalone SMR Integrated SMR

+ ORC

Standalone

expander

Integrated

expander + ORC

LNG production

(million tpy)

1.00

1.35

0.8 – 1.0

1.0 – 1.2

Relative capital

cost

100%

110%

110%

120%

Table 2.

LNG plant specific refrigeration power consumption

Liquefaction process SMR

SMR + ORC Expander

Expander +

ORC

Specific refrigeration

power (kW/t)

265 – 300

195 – 220

330 – 365

250 – 285