56

LNG

INDUSTRY

MARCH

2016

long-run. If gas prices do rise above the sub US$2/million Btu

levels seen today, Texas LNG’s delivered costs will not rise in

the same proportion as a similar percentage increase in oil

price. This is because oil-linked LNG formulae multiply the

price of oil by a factor relating oil and gas prices (commonly

referred to as the ‘slope’). In the case of Texas LNG, there is,

of course, no relation to oil prices in the formula, and the

relationship to US feed gas prices is a ‘cost-plus’ formula, not

a multiplier. When US feed gas prices rise, Texas LNG’s

delivered LNG prices will rise by the same dollar amount, not

in the same proportion. This is illustrated in Figure 1.

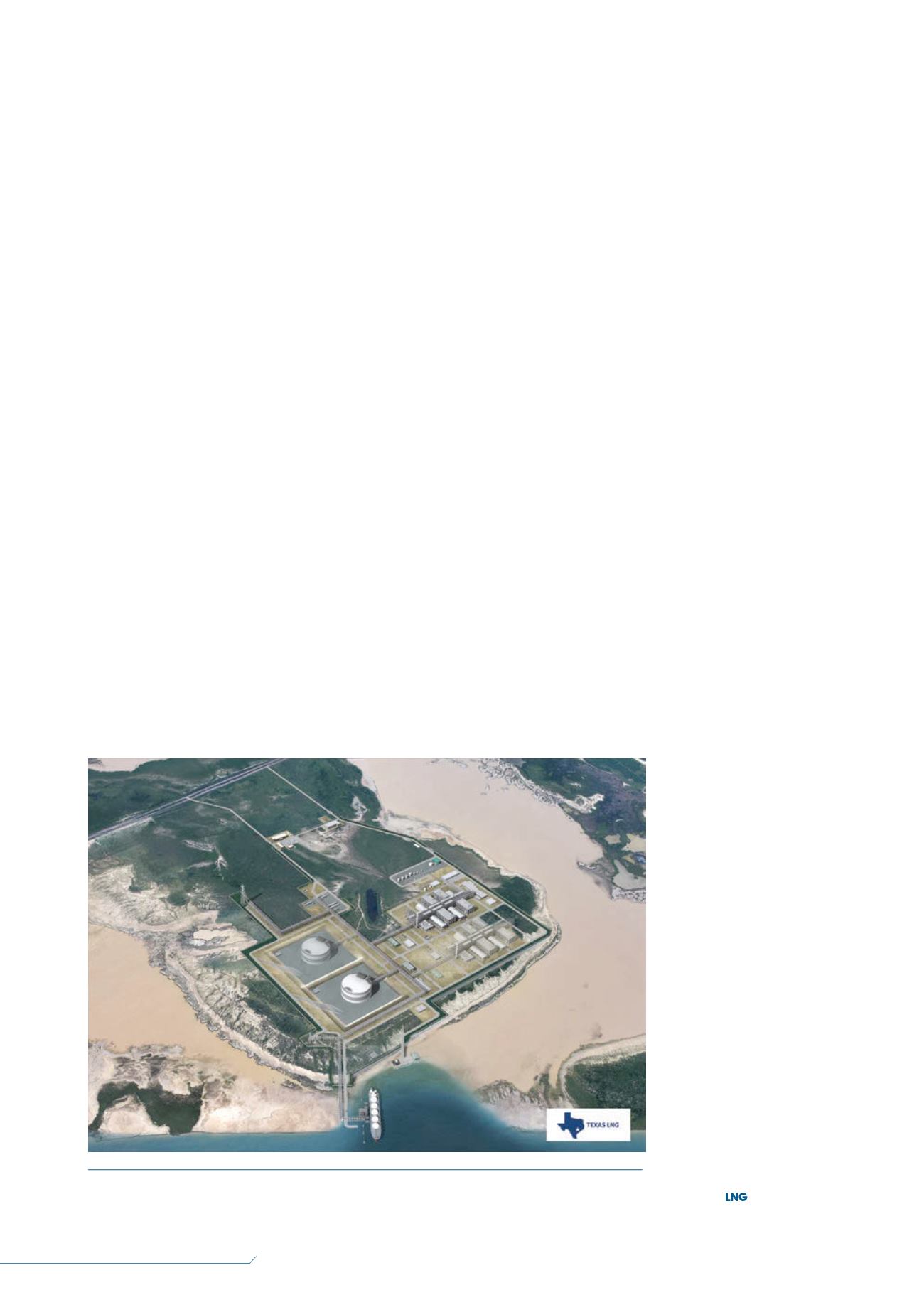

Facility

The Texas LNG site is located on the Brownsville ship channel

– a wide, deepwater channel, approximately 5 nautical miles

from open sea. LNG carriers of up to 170 000 – 180 000 m

3

cargo capacity will be able to dock at the Texas LNG terminal

jetty, allowing for maximum flexibility in the transportation of

LNG from the terminal. The site is close to major natural gas

pipelines and the Eagle Ford basin – one of the major shale

gas basins in the US. Gas can also be sourced from other

suppliers through the elaborate US natural gas pipeline grid.

Texas LNG is a 4 million tpy LNG production facility to be

implemented in two phases of 2 million tpy each. The on-site

construction cost will be minimised by adopting a modular

construction approach. The modules for the LNG plant will be

assembled in global shipyards, taking full advantage of the

low prices currently quoted by shipyards due to rapidly

shrinking order backlogs and order cancellations for ships and

offshore rigs. Train 1 will have a single LNG storage tank,

currently planned to be 210 000 m

3

, which will be large

enough to fully load the largest LNG carriers able to call at the

terminal. The environmental impact is reduced by the small

size of the LNG production facilities relative to the site and the

use of grid electrical power (rather than on-site gas

consumption or electricity generation), which will also be

beneficial for the FERC approval process.

Founders and partners

Texas LNG was founded in 2013 by three experienced

energy executives: Vivek Chandra, Chief Executive Officer;

Langtry Meyer, Chief Operating Officer; and Mike Maloney,

Chief Technology Officer.

Samsung Engineering of South Korea is a minority equity

partner in the project and is responsible for FEED and

engineering, procurement and construction (EPC). Samsung

will execute the EPC on a lump sum basis, thus minimising

the risk of budget overruns for the developers and their

financial backers.

Braemar Engineering has been engaged by Texas LNG to

act as owner’s engineer, overseeing the design process and

leading the FERC filing process.

Third Point LLC, a New York based investment fund with

approximately US$17 billion in assets under management, has

taken an equity interest in the Texas LNG project and has

provided development capital for the project.

Project schedule

The development of the Texas LNG project is progressing

on schedule and all major milestones have been achieved

on time. The conceptual design, pre-FEED and FEED have

been completed, and the detailed engineering works will

begin shortly. The FERC pre-filing process is underway and

all 13 draft Resource Reports were filed in 2015. The main

engineering report, Resource Report 13, was submitted in late

September 2015. The EPC phase is scheduled to start in 2017,

with start-up of LNG production scheduled for 2020.

In June 2014, the company was granted approval to

export 2 million tpy of LNG to countries that hold a Free

Trade Agreement (FTA) with the US. Approval to export

4 million tpy to FTA countries

followed in September 2015.

The project’s non-FTA export

approval is pending.

Conclusion

The realistic capacity

target, the use of low cost

US feed gas and the low

cost modular construction

philosophy to keep overall

CAPEX down, as well as its

strategic location for exports

to emerging markets in

the Americas and Europe,

will make Texas LNG

commercially viable in

a changing market. The

use of proven technology

in liquefaction and LNG

storage will create a low

risk investment opportunity

for the project’s financial

backers and provide security

of supply for the LNG

offtakers.

Figure 2.

Texas LNG’s 625 acre site along the Brownsville Ship Channel, 5 nautical miles from the

Gulf of Mexico.