58

LNG

INDUSTRY

MARCH

2016

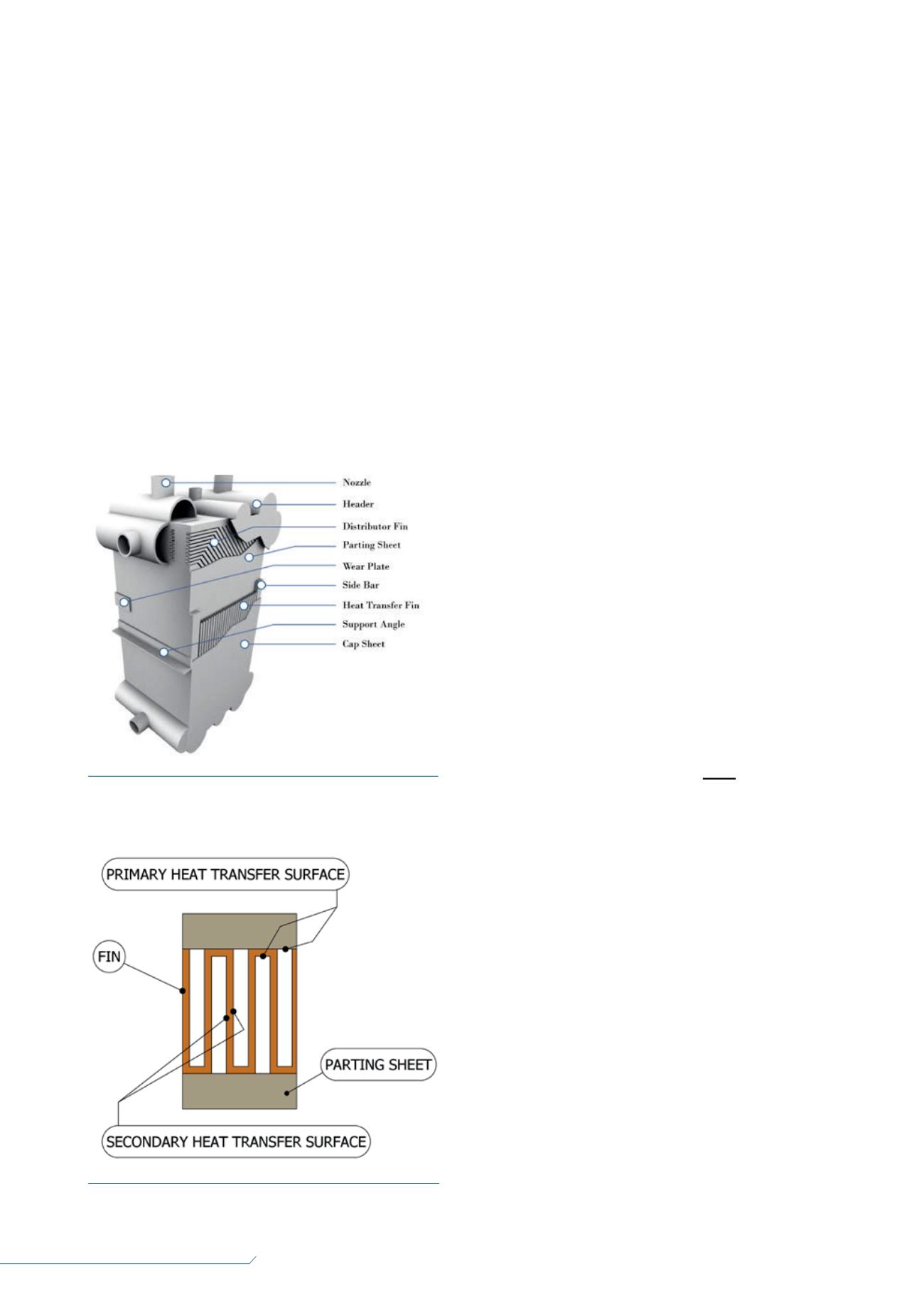

Plate-fin heat exchanger

A BAHX, as defined by ALPEMA

1

, consists of a block (core) of

alternating layers (passages) of corrugated fins. The layers are

separated from each other by parting sheets and sealed along

the edges by means of side bars, and are provided with inlet

and outlet ports for the streams. The block is bounded by cap

sheets at the top and bottom. A figure of a BAHX with some

segments cut away so that the internals can be seen

2

is shown

in Figure 1.

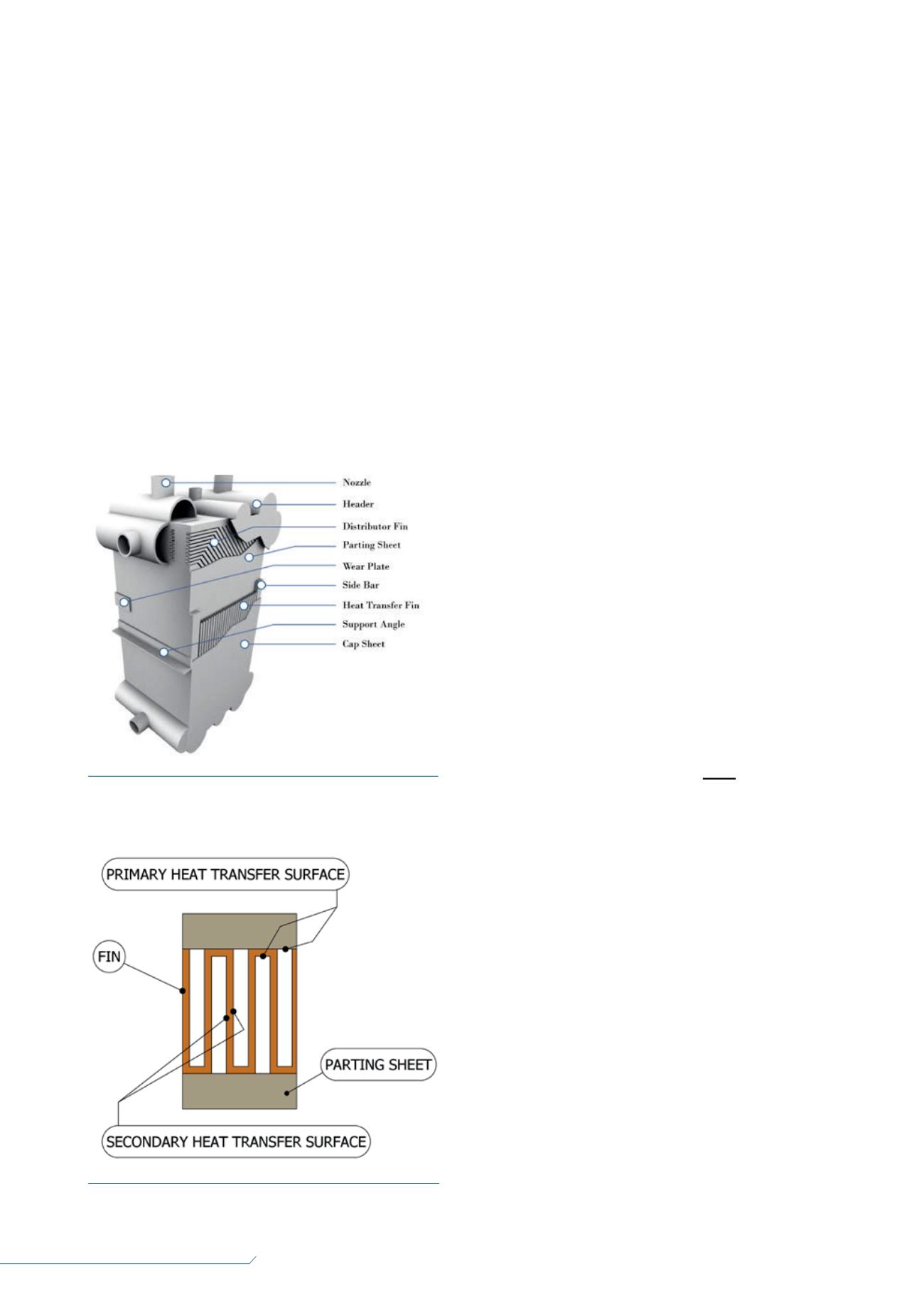

Heat transfer and pressure

drop

While a BAHX is typically larger than a vehicle, it is important

to remember that all heat transfer is local at the millimeter

level. Heat transfer in a BAHX takes place almost entirely by a

convection mechanism between the fluid and the metal, which

is comprised of a fin and parting sheet. A fin height is typically

6 – 10 mm and a fin spacing is typically 1 – 3 mm, yielding

a channel size range of 1 mm x 6 mm to 3 mm x 10 mm. An

example of the cross section of a plate-fin structure is shown

in Figure 2.

Once a fluid is flowing in a channel, there is usually very

little communication with the fluid in the other channels.

The sensitivity of heat transfer to the flow distribution

among channels is examined in the following analysis. The

governing convection equation is:

Where q is the amount of heat transferred, h is the

convective heat transfer coefficient, A

p

is the primary heat

transfer surface area,

η

is the fin efficiency, A

s

is the secondary

heat transfer area, T

w

is the wall temperature, and T

b

is the fluid

bulk temperature.

For single phase heat transfer, the convective heat transfer

equation is:

Where j is the Colburn j factor (dimensionless heat transfer

coefficient), G is the mass velocity, Cp is the heat capacity, and

Pr is the Prandtl number. The Colburn j factor as a function of

flowrate can then be expressed in the form:

Where A is a constant with respect to the flowrate, Re is

the Reynolds number, and N is typically between -0.7 and -0.2.

For a given fixed geometry, removing thermophysical

properties and substituting equation 3 into equation 2 yields:

Pressure drop in a fin channel can be characterised by the

equation

3

:

Where Δp is the pressure drop, f is the Fanning friction

factor, L is the channel length, D is the hydraulic diameter, G is

the mass velocity, and ρ is the fluid density.

Test data for plate-fin structures

4

has found that f can be

expressed in the form:

Rearranged for the mass velocity:

Combining equation 7 with equation 4:

Equation 8 demonstrates that the heat transfer coefficient

is proportional to the pressure drop along a pressure drop

path, but, with the exponent of 0.3 to 0.4, the heat transfer

coefficient is not extremely sensitive to pressure drop changes.

Therefore, developing uniform heat transfer coefficients

should tend toward stability when fluctuations are

Figure 1.

Brazed aluminium heat exchanger sketch with some

segments cut away so the internals can be seen.

Equation 1: q = h (A

p

+

η

A

s

) (T

w

– T

b

)

Equation 2: h = j G Cp Pr

-2/3

Equation 3: j = A Re

N

Equation 4:

h

∝

G

(0.3 to 0.8)

Equation 5: Δp = 4f L G

2

D 2р

Equation 6: f = A Re

(-1.0 to -0.1)

Equation 7:

G

∝

Δp

(0.5 to 1.0)

Equation 8:

h

∝

Δp

(0.3 to 0.4)

Figure 2.

Cross section of a plate-fin layer.