62

LNG

INDUSTRY

MARCH

2016

outlet distributor type; and different inlet vs outlet distributor

finning. The left hand side flow path and right hand side flow

path through the heat transfer finning (2) are identical.

Therefore, even flow distribution through the layer can be

promoted by increasing the pressure drop in the heat transfer

finning (2) relative to the pressure drop in the entry distribution

finning (1) and the exit distribution finning (3).

Commercially available software can calculate distribution

finning and heat transfer finning pressure losses. Chart designs

each stream’s layers to promote uniform flow distribution. As

this calculation is on a single layer basis, there are no scaling

issues when more layers are added. This technique has been

proven in service for the IPSMR process at plant sizes of

0.3 million tpy, and other LNG processes up to 5.2 million tpy.

Pitch

A pitch is a group of layers that are repeated a number of

times along the exchanger height. A pitch is generally the

basic group of layers that exchange heat with each other. A

typical pitch may only be 3 or 4 in. along the stack height. A

design goal for a pitch is to provide uniform heat transfer in the

pitch so that it is essentially an adiabatic entity. An example of

a six-layer pitch for a heat exchanger in an LNG application is

shown in Figure 4, where LPR is low pressure refrigerant and

HPR is high pressure refrigerant.

Chart calculates the heat transfer performance of the

exchanger (and, therefore, all of the pitches), utilising

commercially available software. While the pitch arrangement

varies significantly from design to design (BAHXs can have

anywhere between two to more than 20 streams), the general

concept is to maximise the number of essentially adiabatic,

and symmetric pitches, while minimising the overall BAHX

size.

Block

When the required volume of flow is more than one pitch can

handle, a stack of pitches is used to form a block. A block is a

collection of pitches stacked on top of one another up to the

maximum height that can be brazed into a single block. Very

little heat is exchanged between the different pitches in the

block when they are stacked together, since effort is made to

design the pitch per the criteria.

In scale-up, the number of pitches can be increased as

needed to meet the total flow requirement, as long as the flow

distribution entering each layer remains the same. As already

stated, it is desirable to design as much pressure drop into the

layer as allowed and minimise other losses.

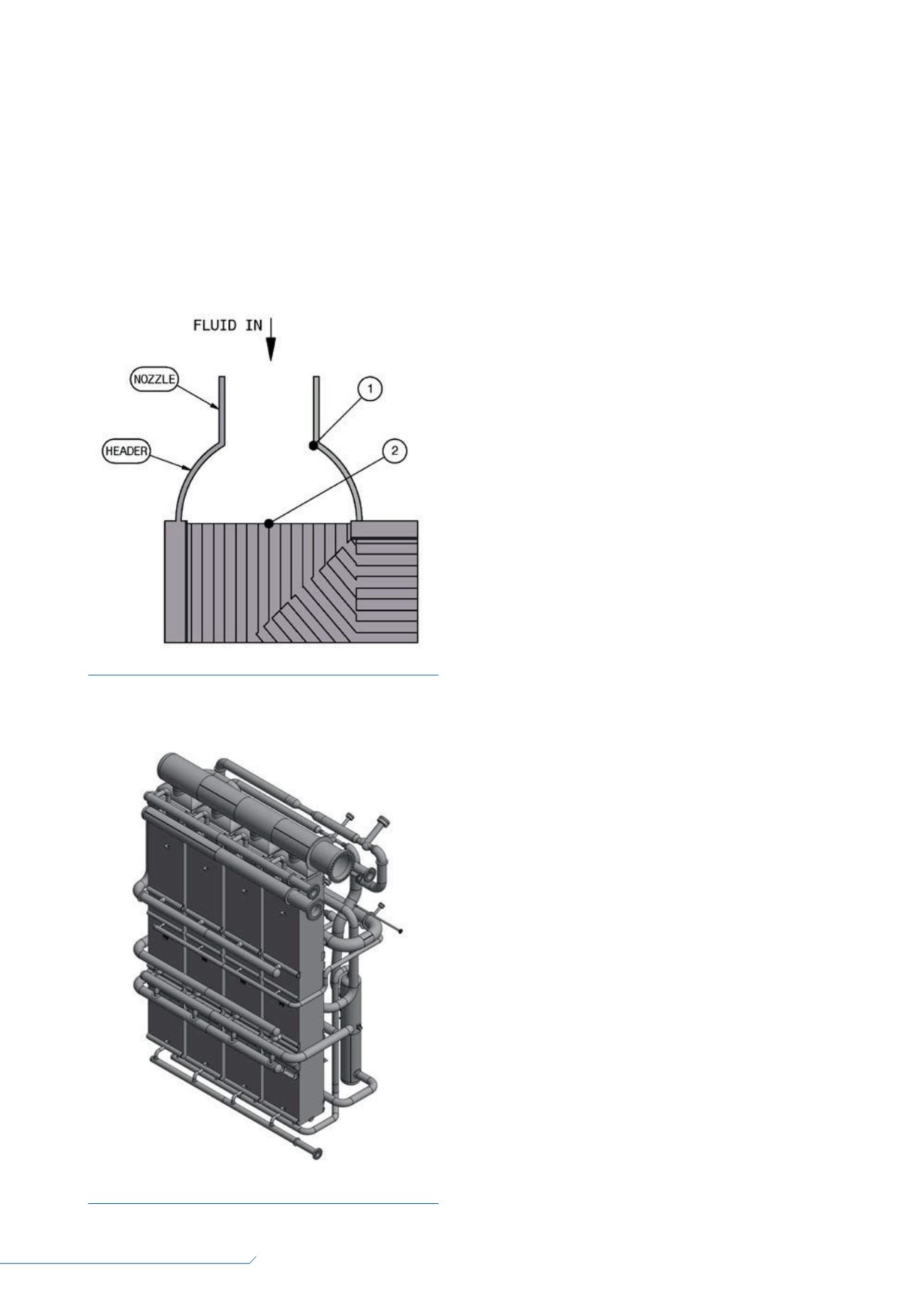

The nozzle is a stub pipe that is used to connect the

exchanger to the process piping. The nozzle connects to a

header, which is used to distribute the flow to the entry or exit

ports of the layers associated with that stream. There is an

expansion/contraction pressure loss associated with the

nozzle to header transition (1), and the header to port transition

(2), as shown in Figure 5. These pressure losses are calculated

in commercially available software.

Chart has methodology to analyse the distribution of flow

through the header to each individual pitch. It has calculated a

maximum mass flow difference of 4% between pitches for a

worst case exchanger design/operating case for the IPSMR

process. The maximum mass flow difference between pitches

for typical IPSMR designs is approximately 2% at design

flowrate.

Even distribution of the flow from the header to the

individual ports is achieved due to the negligible pressure drop

associated with flow through the header relative to the

pressure drop associated with the layers.

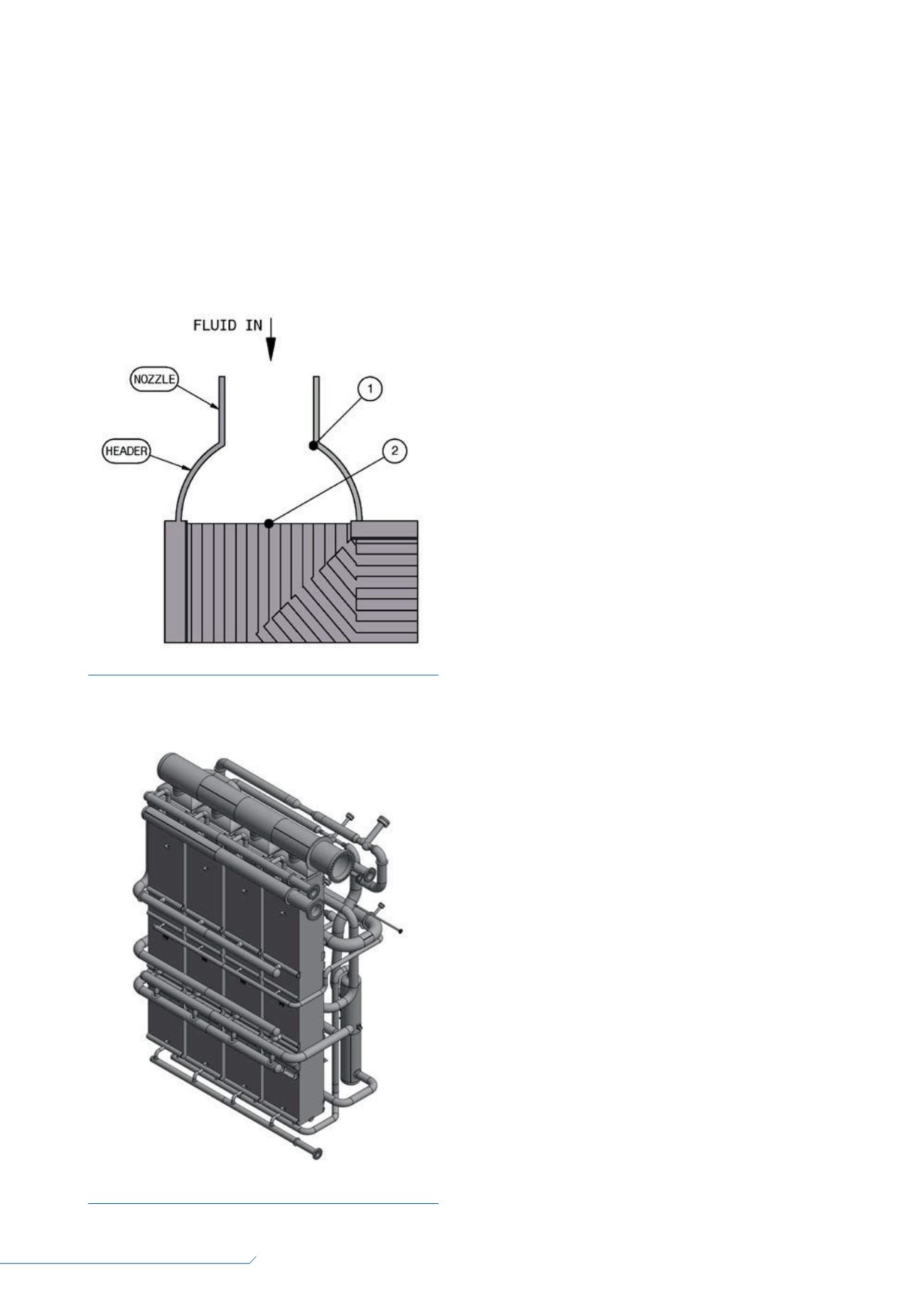

Battery

When the required volume of flow is more than one block

(one stack of pitches) can handle, multiple blocks of heat

exchangers are piped together in parallel to perform as one

heat exchanger. A group of blocks piped together is called a

Figure 5.

Example of a nozzle and header.

Figure 6.

Example of a multi-core battery.