68

LNG

INDUSTRY

MARCH

2016

Some features are customisable, including the following:

Efficiency: counter-current heat exchanger systems are

designed to minimise resistance to fluid flow through

the exchanger and maximise the heat transfer surface

area between streams. This can help to reduce OPEX by

decreasing energy consumption and increasing process

efficiency.

Compactness: BSSHXs are capable of being reduced

in both size and weight. This can make them useful in

offshore applications, where lighter weight can result in

reduced CAPEX.

Availability: PFHEs are known to be robust and easy to

repair and maintain if they are used in adequate operating

conditions. Moreover, high temperature gradients and

high pressure loads can be managed within this brazed

PFHE structure. Suitable material can also be used to

improve corrosion resistance.

Competitive price: heat exchangers are completely brazed

in one piece in a dedicated vacuum furnace. Brazing is

not a restrictive assembling process, and is considered

as smooth and flexible. As a consequence, complex

configurations, including many different components

(bars, fins, parting sheets), which vary in thickness (from

0.1 mm to 20 mm), can be brazed all together in order to

become a one-piece core. The right quantity of material is

then used to produce an optimised heat exchanger at the

best cost.

Gas compression system: an

omnipresent process

Gas compression systems are widely used in many industrial

plants (natural gas processing plants, petrochemical and

chemical plants, end-product gases, etc.), where higher

pressures and lower volumes of gas are sought.

The design of a gas compression package is imposed by

the project development philosophy of the field. It has to

cover a large range of operating conditions and

accommodate a combination of different process conditions

(variable suction pressure, varying mass flow, highest

discharge pressure, etc.). These often require the system to

have several stages of compression, which can usually be

provided with intercooler exchangers.

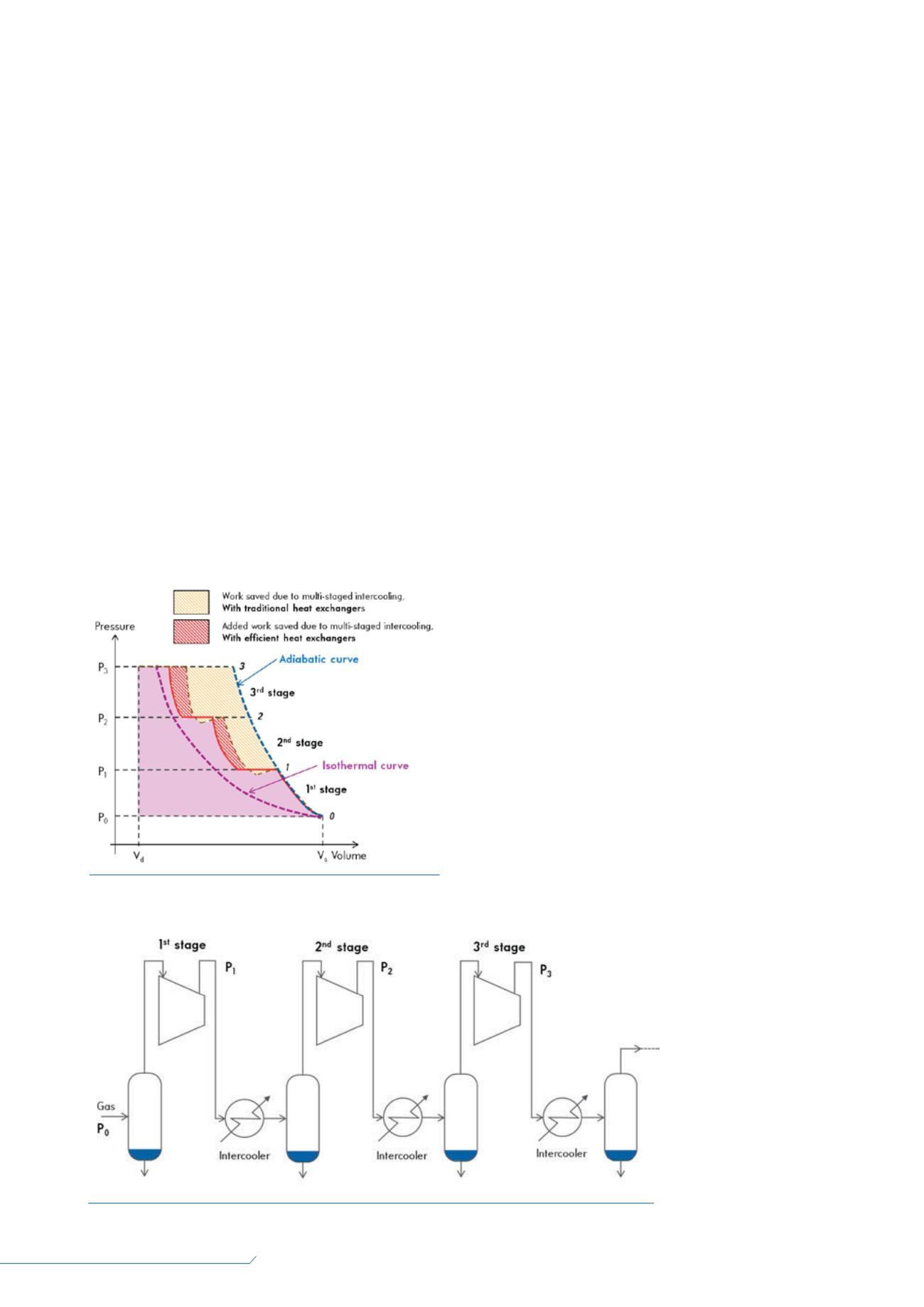

Multi-staged unit with intercoolers principle

The gas enters the first compressor (P

0

) and then exits at the

first pressure level (P

1

). Inevitably, the temperature will also

increase. The gas is then cooled down in the intercooler, in

order to achieve a suitable temperature level for the next

compression stage. Condensed liquid is constantly removed

from the gas stream prior to each compression stage, using

a free water knock-out drum. The gas phase enters a new

compression stage and the process starts again.

The influence of design parameters

In general, both technical and financial considerations impact

the intercooler choice, especially in an offshore application.

Inevitably, an intercooler exchanger has to fit the process

functioning specifications, which can include different operating

conditions. The heat exchanger design is then optimised

according to various parameters, e.g. safety, expected thermal

performance, pressure drop requirements, weight, size, etc.

However, the main decision on any project is how to

achieve the best balance between CAPEX and OPEX. This

impacts the entire plant configuration, including the design of

the heat exchangers. The most cost-effective option has to be

picked among different competing alternatives, which could

have different initial costs, operating costs, maintenance

costs, and possibly different life cycles. For example, in

offshore applications, the weight of the topside plant affects

the overall economics of

the project. Indeed,

minimising the total

weight of the topside

structure heavily impacts

the supporting structure,

which could represent half

of the total price of the

system (FLNG, FPSO, etc.).

Thus, maximising the

efficiency of the system

would lead to energy

consumption minimisation

during operation, which

would maximise revenue.

Therefore, engineers

have to find the best

Figure 2.

Multi-staged gas compression system principle.

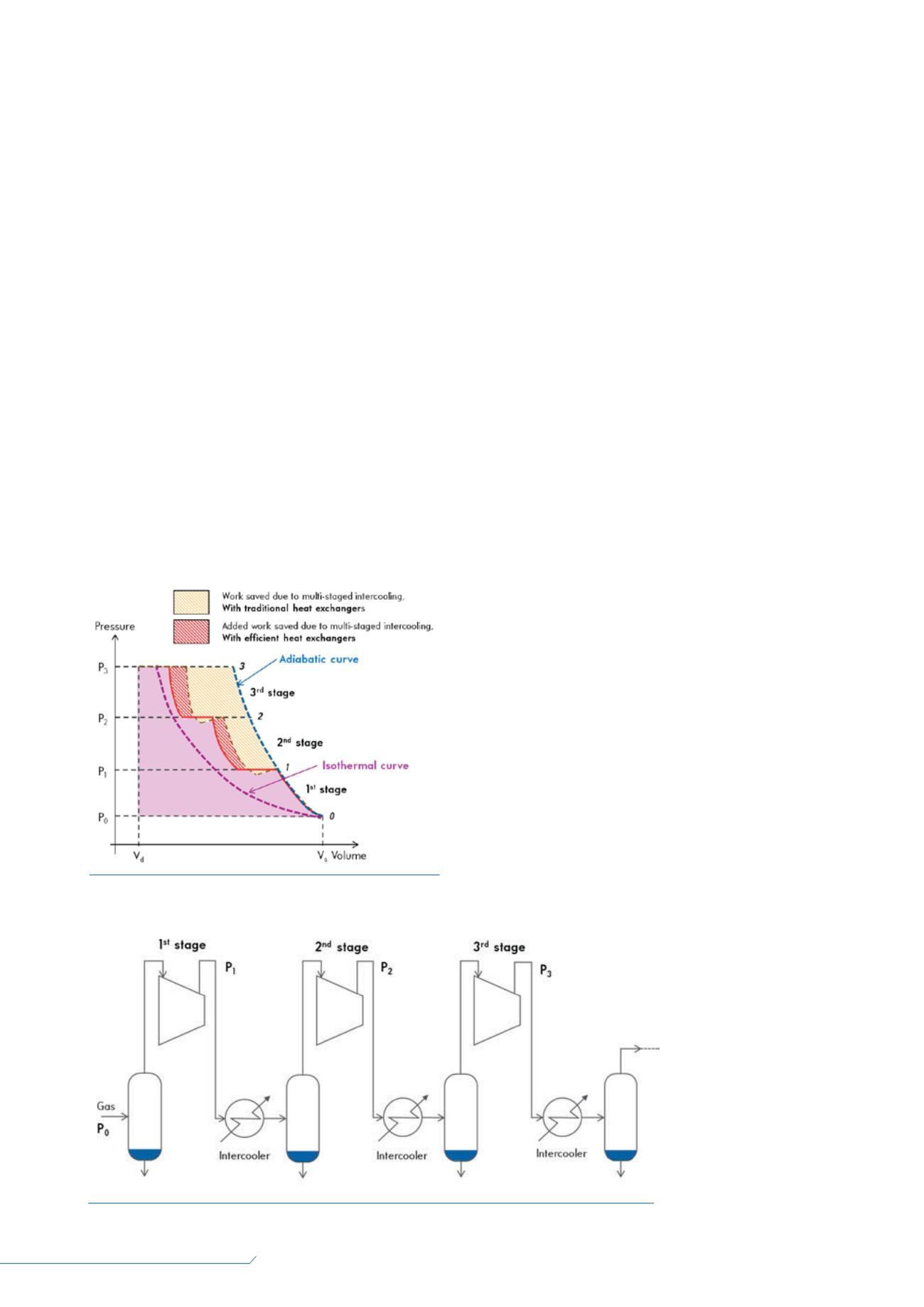

Figure 1.

Pressure-volume compression diagram for

traditional and compact heat exchanger technologies.