60

LNG

INDUSTRY

MARCH

2016

encountered, even when a heat exchanger design has

non-uniform pressure drop paths. The heat transfer coefficient

will vary less than the pressure drop or flowrate does.

Chart has proprietary fin designs, and Fanning friction f

data and Colburn j data for each fin design is based on

experimental testing. Commercial software is available to

calculate heat transfer and pressure drop performance for

these surfaces not only for single-phase fluids, but also for

two-phase fluids. Two-phase fluid heat transfer and pressure

drop principles are similar to single-phase fluids in that heat

transfer coefficients and pressure drop are also a function of

mass flux.

Distribution

In a BAHX, pressure drop of a single stream among multiple

flow paths will always be equal; flow to each path will vary

such that the pressure drop is the same. Therefore, to promote

uniform flow distribution, one must promote uniform pressure

drop. This also implies that one must have the ability to

calculate pressure drop for multiple flow paths. Chart has

the ability to rate heat transfer performance with varying

distribution of flow.

After performing many rating calculations, the company

has developed design guidelines on how uniform the flow

distribution must be and how to promote uniform flow

distribution. One technique that is useful in promoting uniform

distribution is to maximise the pressure drop in the location

where it is desired to have uniform flow (heat transfer finning,

two-phase distribution devices), while minimising other

pressure drops. The weak dependence of the heat transfer

coefficient as a function of flowrate helps to dampen

fluctuations and give uniform thermal performance in a BAHX,

as the heat transfer coefficient will generally vary less than the

pressure drop or flowrate does.

Achieving proper flow distribution through uniform

pressure drop is less predictable for two-phase streams. The

large density difference between the liquid phase and the

vapour phase in a two-phase stream can cause flow

maldistribution, particularly in parts of the exchanger with

large open cross sections, such as the manifolds and the

headers. Maldistribution of a two-phase stream can have a

significant impact on the actual exchanger performance vs the

simulated exchanger performance. The liquid will take

significantly less of the heat transfer area/volume due to its

higher density than the vapour phase, but the liquid phase has

higher heat transfer coefficients and a higher duty (in boiling

services). Therefore, assessing the impact of two-phase

distribution and developing design criteria to avoid two-phase

maldistribution is critical.

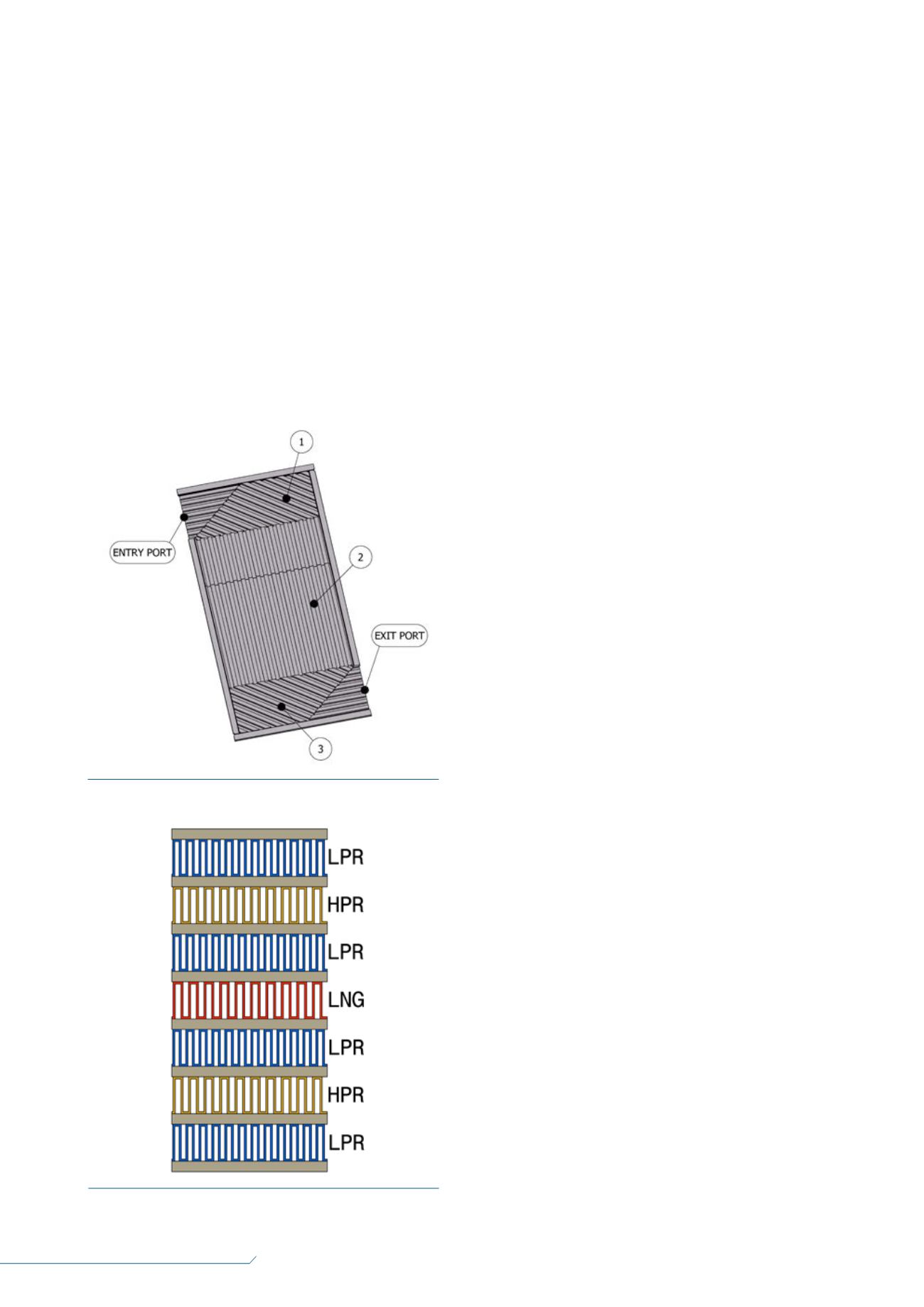

BAHX construction

Layer

A layer contains the flow of a particular stream, and the layers

are separated from each other by parting sheets (the outer

most layers are sealed on the ends by a cap sheet) and sealed

along the edges by side bars. As shown in Figure 3, a simple

layer has one stream with an entry port and distributor (1), a

heat transfer section (2), and an exit port and distributor (3).

Layers can be more complex, with multiple streams entering

a layer, but this example is limited to a simple layer. Layer

heights are typically 0.375 in. or 0.25 in. Layers are typically

4 ft wide and can be more than 20 ft long. The small layer

heights and variety of Chart fin geometries allow for optimised

velocities for each stream, unlike shell and tube exchangers,

in which the shell velocities are dictated by the tube bundle

geometry.

Flow maldistribution can occur due to the different flow

path along the left side vs the right side of the layer. For

example, in Figure 3, the left hand side will have a lower

frictional pressure loss in the entry distribution finning (1), and a

higher frictional pressure loss in the exit distribution finning (3)

relative to the right hand side. Therefore, it is desirable to

configure the entry distributor and the exit distributor to

balance the pressure drops through the left side vs the right

side flow paths. Note that balancing the left hand vs the right

hand pressure drops usually does not mean equivalent

distributor sizes, due to the following reasons: change in fluid

density with temperature and/or phase; different inlet vs

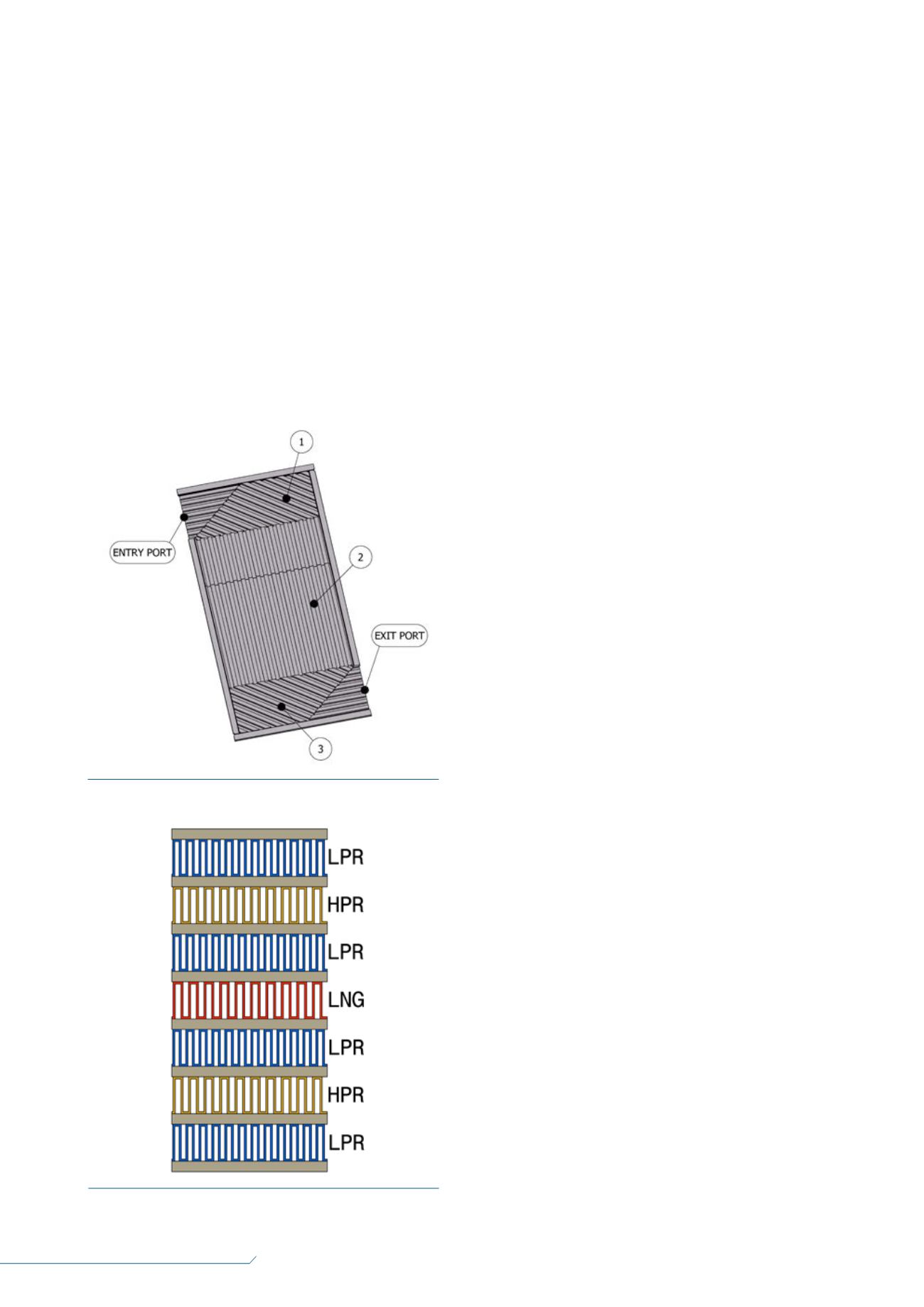

Figure 4.

Example of a pitch of layers in a heat exchanger in an

LNG application.

Figure 3.

Layer geometry.