process design solution to balance initial monetary

investment with the long-term expense of owning and

operating the plant, according to available and suitable

technical solutions.

Using a steel PFHE as an

intercooler

Some large compressors require several MW of power to run.

Consequently, a slight improvement in efficiency can result in

large energy savings.

Figure 1 represents the pressure-volume diagram for four

different compression system configurations:

The adiabatic curve represents the isentropic

compression, with only one unique staged compression,

but requires the maximum work.

The isothermal curve, which represents the ideal

single-staged compression, at constant temperature,

requires the minimum work. But this case is only

theoretical and not possible in practice.

The brown curve shows how a multi-stage compression

system can increase overall efficiency of that system. The

compression curve moves towards isothermal by means of

standard intercoolers between each compressor stage. The

cooler the gas is, the better the compression efficiency is.

The red curve shows the improvement brought by the

use of more efficient intercoolers. The compression curve

moves closer to isothermal, which means that the overall

gas compression efficiency rises significantly.

In brief, efficient heat exchangers used as an intercooler

have several advantages on the overall gas compression

system performance, including the following:

Compression temperature profile approaches close to

ideal isothermal functioning, so the work done by the

compression system is reduced. Thus, less power is

required to deliver the same quantity of gas at a given

delivery pressure.

It increases the volumetric efficiency for the same

compression ratio.

The machine can be smaller.

Mechanical problems are minimised due to a lower

operating temperature.

Effects from moisture are better dealt with by favouring

the drainage of condensate at each compression stage.

The lubricating system is less impacted by high delivery

temperature.

The low pressure cylinder may be lighter.

Conclusion

BSSHXs respond to more stringent specifications, and

seek to find the best compromise between both technical

performance and best return on investment (ROI). They are

particularly suitable for offshore gas compression systems.

The heat exchangers’ options are fully customisable to find

the best compromise between thermal and pressure drop

performances, cost and weight, while optimising availability, in

order to improve the overall process solution.

Proven LNG

Capabilities

Our 20,000-strong Oil & Gas professionals deliver end-to-end

services to our clients in the global LNG sector.

We offer capabilities in:

›

Liquefaction plant build

›

Completions and commissioning

›

Non-process infrastructure

›

Marine infrastructure

›

Operations and maintenance

›

Telecommunications

›

Re-gasification and receiving terminals

›

Off-sites and utilities

›

Gas processing and handling

›

Pipelines and compressor stations

snclavalin.com

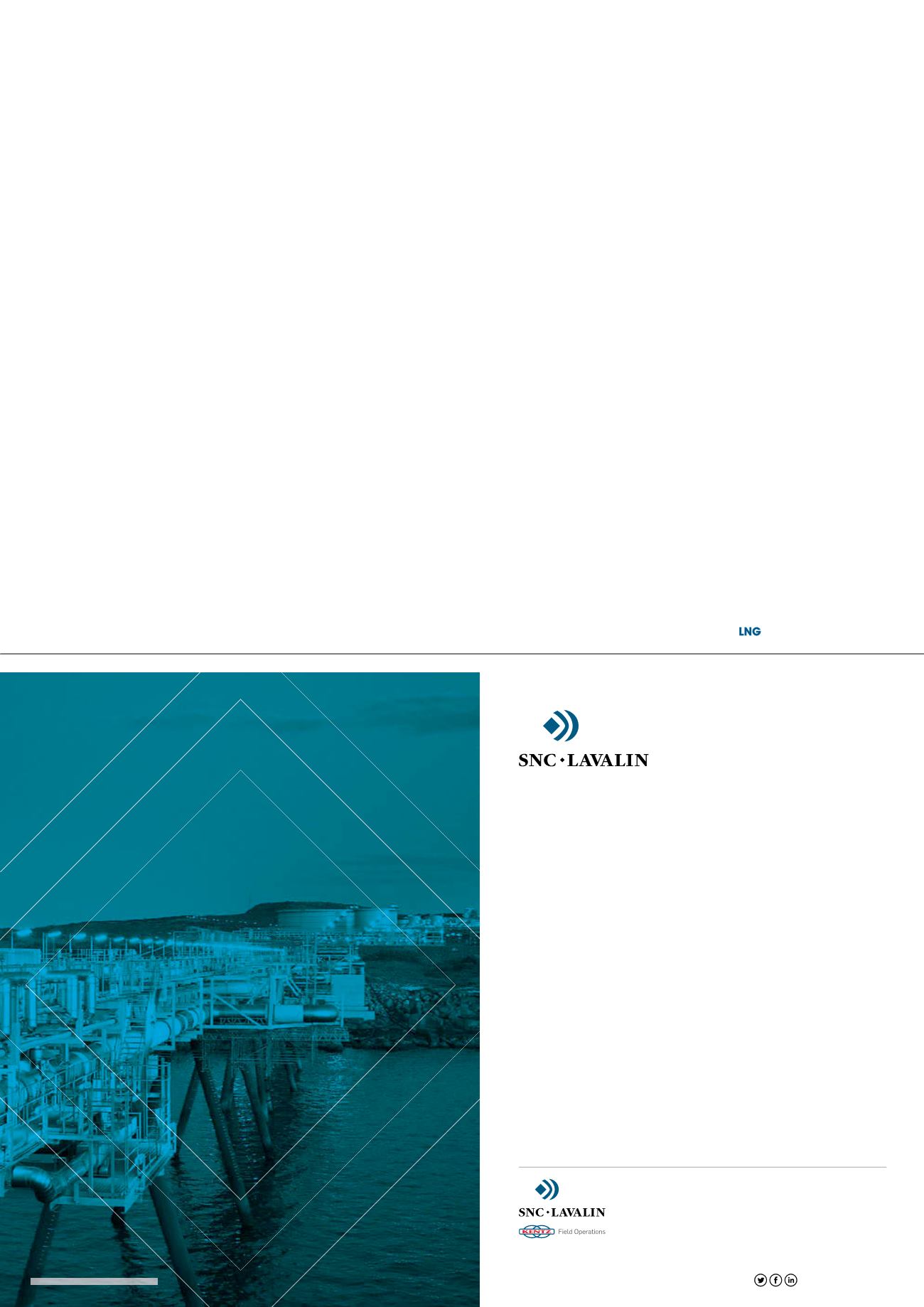

Pluto LNG, image courtesy of Woodside

SNC-Lavalin Field Operations is world renowned

for providing multi-disciplinary construction

and technical field services.