64

LNG

INDUSTRY

MARCH

2016

battery or assembly, and the connecting piping is referred to

as manifolds (Figure 6).

There is an expansion/contraction pressure loss

associated with the flow transition between the manifold and

nozzles. Commercially available software can be configured

using standard pipe network methodology to assess the

impact of flow distribution in the battery. Each block is

modeled as an individual exchanger in a pipe network. For

distribution purposes, it is desirable to design as much

pressure drop into the block as allowed and minimise the

piping losses in the manifolds (this minimises the flow

maldistribution from block to block).

Two-phase inlet distribution

Proper flow distribution for a two-phase inlet stream is less

predictable. Therefore, the following methodology to assess

the impact of two-phase maldistribution, and design criteria

to avoid two-phase maldistribution, is utilised for two-phase

streams in Chart’s IPSMR process. The first step is to assess

if a stream is in two-phase flow during any steady state

operating cases. If it is, then a flow regime analysis can be

performed to evaluate the flow characteristics of the stream.

For two-phase streams in a flow regime of concern (slug

flow, annular flow, etc.), two-phase maldistribution can occur.

Chart has developed a method to assess the potential effect

of two-phase maldistribution on the exchanger performance.

This method varies the amount of mixing of the liquid with the

vapour in the two-phase stream (from fully mixed to complete

phase separation), and measures the impact on the stream

temperature and thus the exchanger overall heat transfer

coefficient per unit area (UA). As the amount of liquid mixed

with the vapour decreases, the UA required increases due to

the changing mixture temperature pinching the cooling curve

of the exchanger.

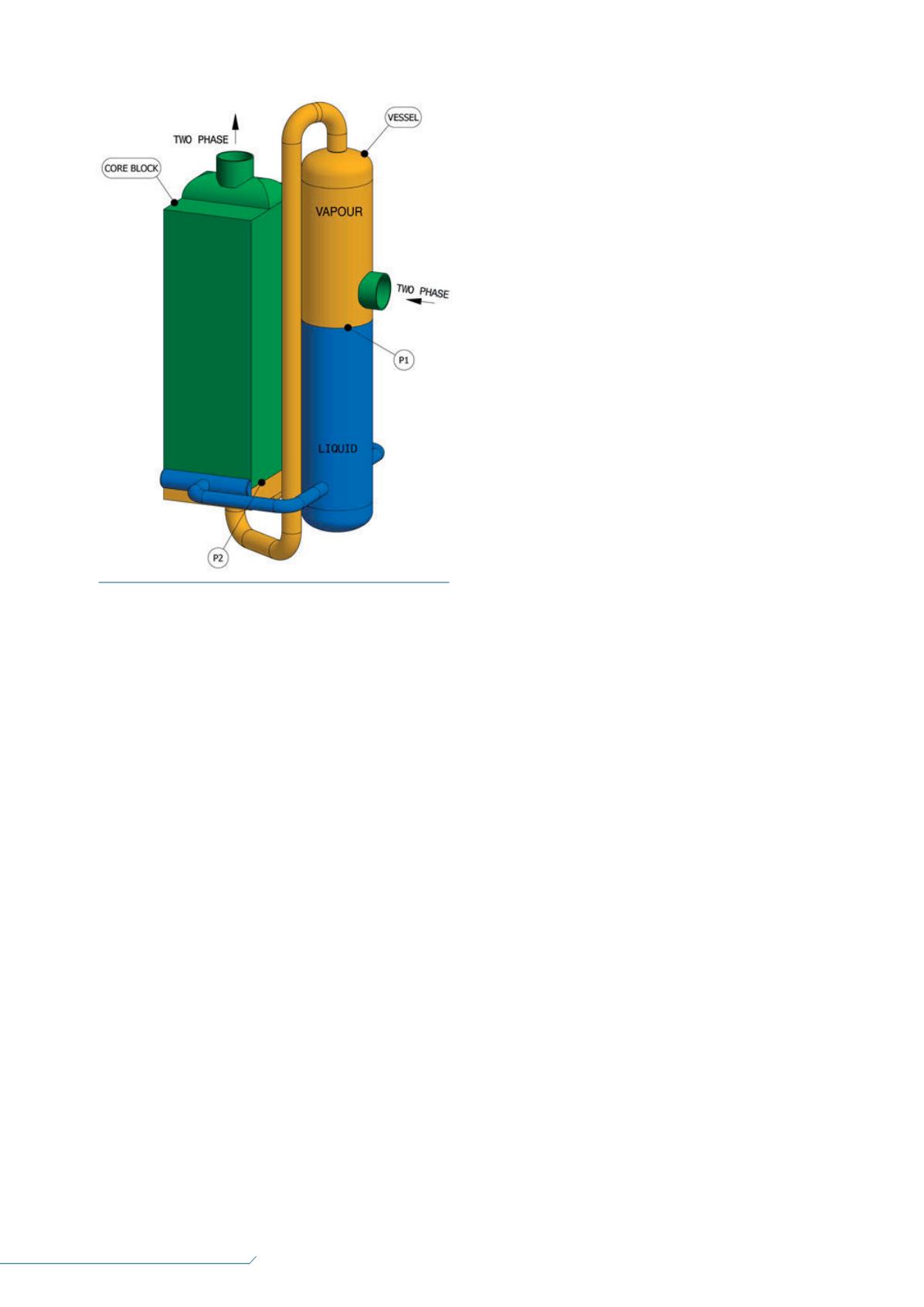

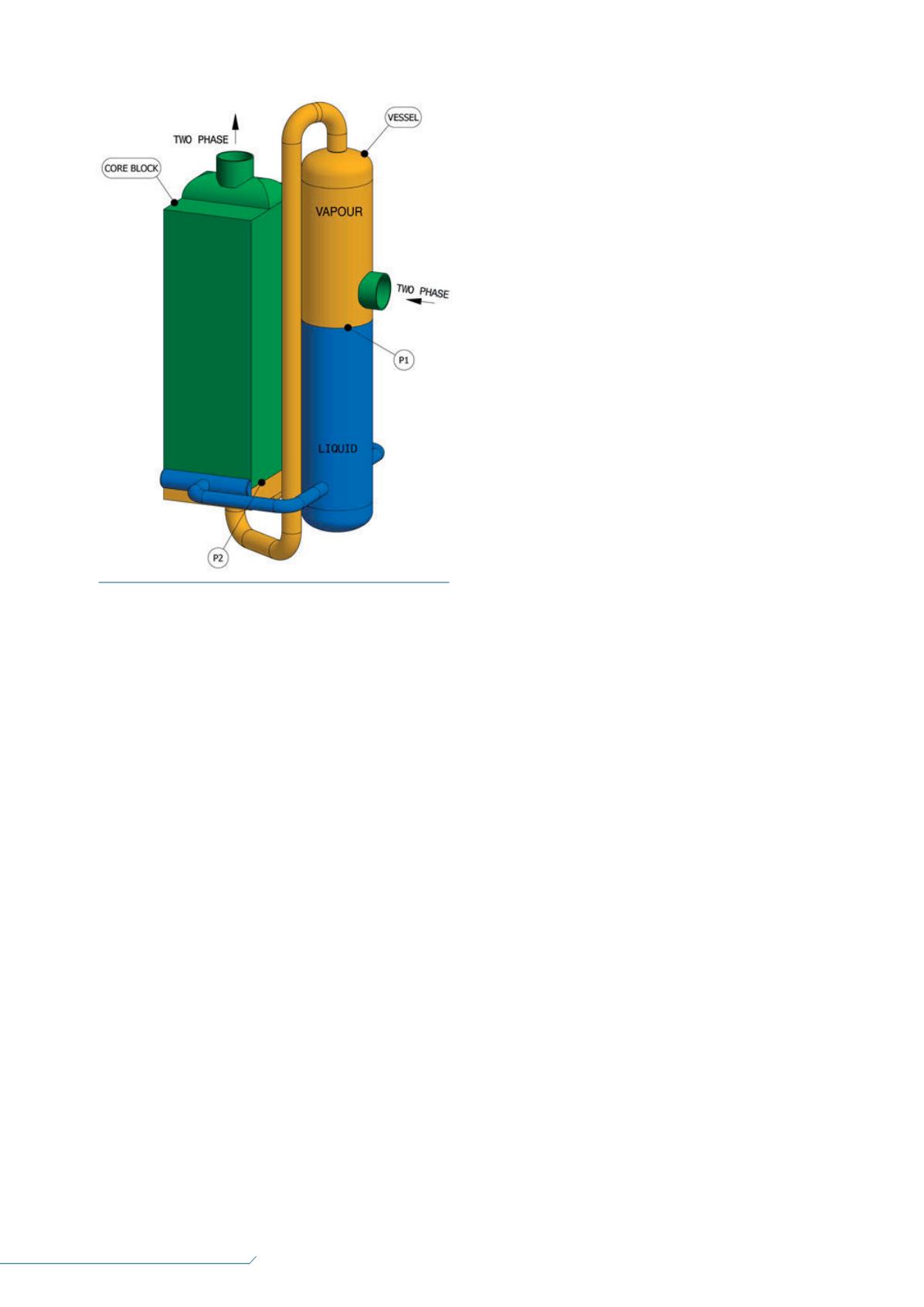

In some cases, separating the liquid and vapour and then

introducing them in a controlled manner may be

advantageous. For two-phase streams where the UA increase

associated with the mixing percentage with no device or

perforated plate is detrimental, or for manifolded assemblies

of exchangers (where two-phase flow separation can occur

not only within the individual core header, but also within the

manifolding piping), a separation vessel and a two-phase

distribution device are used. Separating the liquid from the

vapour in a vessel, and then separately manifolding each

phase, ensures that equal amounts of liquid and vapour are

sent to every individual core block. Two-phase distribution

devices can be inserted at the inlet of any stream or any point

along the core length for any stream. A model of the layout of

the separation vessel, core, and piping is shown in Figure 7.

The liquid distribution is controlled by having most of the

liquid path pressure drop located in the liquid distribution

device. The liquid pressure drop, due to other factors (nozzles,

manifolds, piping), is kept low, so the liquid path pressure drop

from P1 to P2 is mostly at P2.

Chart has developed state-of-the art liquid distribution

devices that are incorporated within the core block for BAHX

designs for its IPSMR process. These liquid distribution devices

allow the introduction of mixed refrigerant (MR) into the heat

exchanger at precise locations along the heat exchanger to

‘tune’ the boiling refrigerant cooling curve and provide a very

efficient and robust single mixed refrigerant (SMR) process.

The vapour distribution device exit openings are sized to

keep the vapour velocity sufficiently high to prevent liquid

runback. The pressure drop, due to other factors (nozzles,

manifolds, piping), is kept low.

The liquid level in the vessel relative to the distribution

device is determined by the difference in pressure drop

between the liquid path and the vapour path from P1 to P2.

Since the two-phase distributor devices are static, the

range of liquid and vapour flowrates to meet design criteria

and maintain good distribution is limited. Chart has performed

numerous designs for its IPSMR process, and confirmed that a

flow range of 50 – 110% of design flow can be achieved with

uniform distribution.

The vessel diameter is sized to reduce the vapour velocity

in the vessel to prevent entrainment of the liquid by gravity

separation. For this application, a high degree of separation is

not required. The company has developed guidelines for

vessel sizing from a variety of sources, including HTRI

5

, GPSA

6

,

and Bechtel.

7

These criteria are used to design vessel

parameters, such as aspects of the vessel length and nozzle

sizes.

Conclusion

Thermal performance of a BAHX is dependent on promoting

uniform flow distribution. The essence of promoting uniform

distribution is to maximise the pressure drop in the location

where it is desired to have uniform flow distribution, while

minimising other pressure drops. For single-phase flow, the

heat transfer coefficient typically varies less than the pressure

drop or flowrate does, helping to promote uniform thermal

performance.

Commercially defined methodology and commercially

available software can be configured to evaluate the impact of

Figure 7.

Layout of separation vessel, core and piping.