74

LNG

INDUSTRY

MARCH

2016

of the products are also reasons for heat tracing. Viscous

products must be heated for transport. The formation

of waxes (paraffins) may occur during the oil and gas

production phases in some equipment (e.g. separators)

on offshore production platforms. Electrical heat tracing

can prevent wax and hydrate formation on separators,

which might impair the operation of instruments and

create blockages of process piping. Additional oil and gas

process equipment that requires heat tracing includes

test separators, first and second stage separators, lift gas

systems, compressors, scrubber lift gas modules, fuel gas

systems, etc. Besides the process equipment, these areas

are also required to have freeze protection for operations

and safety purposes, loading and unloading lines, gas

vapour return lines, fire protection lines, strip and cleaning

lines, fuel oil lines, storage tanks and vessels, deck and

tank cleaning lines, engine room fuel and drip lines,

cross-over lines, manifolds and safety showers. Besides a

reliable foundation heating system for LNG storage tanks,

as the second part of the project, the complete pipeline

system of the plant with all drums and pumps has to be

heated.

The target of trace heating this system is, in addition to

frost protection, temperature maintenance for the

production process. In the frost protection areas, it is

assured that the temperature does not fall beneath 10°C.

The process temperature is maintained between 15°C and

140°C, exactly as required. Several heating cables and

junction boxes were used, including eltherm’s round

junction box Ex-It-R, which is certified for the hazardous

areas. For the heating of the plant, the eltherm engineers

decided to use the company’s heating cables ELKMAG-N,

ELK-MI-VA, ELSR-N, ELSR-H and ELSR-SH. ELSR-H and

ELSR-SH are self-regulating high temperature heating

cables.

Process temperature maintenance applications require

a properly functioning control system. While the heat

tracing portion of the overall system can be considered the

heart, it is the monitoring and control system that provides

the brains of the operation. Since the heating system must

be capable of operating at all times, redundancy must be

built-in to ensure that if any part of the system fails or

shuts down, its back up is capable of picking up the slack

until the primary mode of operation can be repaired and

restored.

Data integration, communication and user interface

preferences must also be considered when designing an

integrated control system. The control system must be

easily accessible, yet protected from unauthorised access.

The operator should be able to access key parameters

locally, while the system should be capable of transmitting

key data via industry accepted data communication

protocols.

Quarters comfort

In this final area, hot water temperature maintenance and

frost protection of fresh water pipes plays an important

role. Frozen water pipes will burst and damage the

pipeline system, meaning that a reliable supply to the staff

cannot be guaranteed.

Heat load

The three levels of applying an electrical heat tracing

system depend on the ambient temperature, the product

Figure 4.

PLC system for monitoring and control.

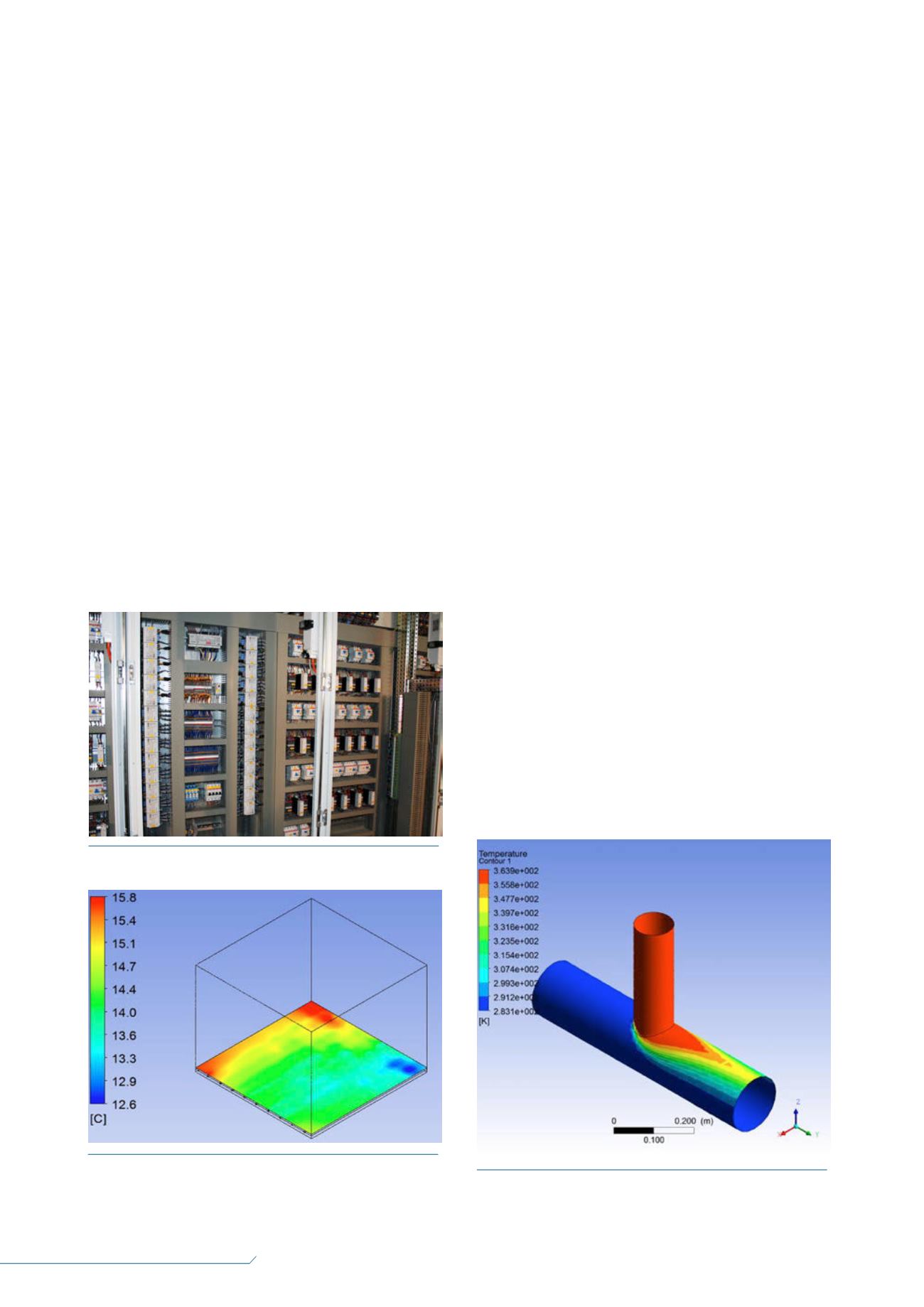

Figure 5.

Sample Finite Element Analysis (FEA). Ambient

temperature = -30°C, room temperature = 15°C, and

wind speed = zero.

Figure 6.

Sample FEA. Ambient temperature = -30°C, room

temperature = 15°C, and wind speed = 20 m/sec.