84

LNG

INDUSTRY

MARCH

2016

Membrane systems

Technigaz designed a membrane type atmospheric LNG

containment systemwith a corrugated stainless steel primary

membrane supported by wooden boxes filled with insulation

material. A secondary cryogenic barrier, also supported

by wooden boxes filled with insulation material, provides

containment of the cryogenic cargo in case the primary

membrane develops a leak. The characteristic corrugations in

the primary membrane allow for the shrinkage of metal under

cryogenic temperatures. This design, identified as the Mark I,

was soon superseded by improved versions and is currently

available as the Mark III series from a number of shipyards in

South Korea and Japan. The Mark V series will soon be put into

production, replacing the current Triplex secondary barrier with

a corrugated stainless steel secondary barrier.

Compatriot, Gaztransport, designed a similar system

consisting of a primary membrane supported by insulation in

plywood boxes and a secondary membrane, also supported by

insulation in plywood boxes. This systemwas called the No 88

system and featured a primary and secondary membrane of a

steel alloy with a negligible contraction coefficient.

Improvements have been made over the years and the current

system is the No 96, which is being used in LNG carriers under

construction in South Korea and China.

After years of competition, Gaztransport and Technigaz

merged to form GTT in 1994. GTT has been developing and

promoting both membrane type containment systems in

parallel, and has licensed these systems to all major LNG carrier

builders around the world.

The main advantage of the membrane type containment

systems is their prismatic shape, which allows these systems to

use the space available within the hull of the LNG carrier to a

very high degree. With the cargo tanks recessed deep inside the

hull under a low trunk deck, membrane type LNG carriers do not

require a high deckhouse to have good visibility. In France, GTT

proposed membrane type LNG fuel tanks for a newbuilding

from Brittany Ferries. Unfortunately, this project was put on hold

for non-technical reasons.

However, both of the membrane systems are vulnerable to

sloshing damage. Sloshing is the motion of the LNG cargo in

the tanks as a result of the effect of waves and wind on the

vessel. In certain circumstances, waves occur in the LNG cargo.

Upon impact with the tank walls, this can cause damage to the

primary barrier and the boxes supporting the primary

membrane. To counter the risk of sloshing damage, GTT advises

that ships are operated with tank levels of more than 90% or

less than 10%. For applications that require part load operations,

such as floating storage and regasification units (FSRU),

membrane systems with specially reinforced boxes have been

developed.

The Moss system

The Moss spherical LNG containment system does not

experience sloshing issues. Its aluminium spheres have

sufficient structural strength to withstand LNG wave impact due

to the interaction between the cargo and the ship’s motion. The

Moss system does not require a full secondary barrier; there

is only a small drip tray below the spheres to catch any liquid

leaking. The design philosophy behind the Moss system is that

the tank should be designed to be strong enough so that cracks

should not develop in the tanks over the lifetime of the vessel.

The structural strength of the containment system is exactly

the reason why old Moss vessels are popular candidates for

conversion to FSRUs or even floating LNG (FLNG) production

plants.

However, the Moss vessels have a low hull space utilisation

rate. The sheers are mounted on the deck of the vessel by way

of an equatorial ring, which means that half the sphere

protrudes above the deck. While this makes for the

characteristic silhouette of the Moss carrier, it also necessitates

a high deckhouse to ensure adequate line of sight from the

bridge. The low hull space utilisation means that a Moss carrier

has a higher gross tonnage

than membrane carriers of similar

cargo capacity, which translates into higher port and fairway

dues and higher tonnage taxes.

The SPB system

The fourth LNG cargo containment system – the SPB system

– combines the advantages of the membrane system and

the Moss system, while also addressing the disadvantages

of both systems. The prismatic shape of the tanks ensures

a high hold space utilisation rate and a low air draft, while

the solid aluminium construction with a

centreline bulkhead and transverse swash

bulkheads reduces liquid motion in the

tanks and minimises the risk of sloshing

damage, even in part load conditions.

The high price of this system originally

prevented wide spread adoption, but in

2014, Japan Marine United Corp. (JMU) – the

successor to SPB designer IHI Corp. –

secured tank orders for four 165 000 m

3

LNG

carriers. With possible licensing overseas,

the SPB system could become a serious

contender in the LNG containment system

arena. In Japan, JMU has already carried out

a study with a shipyard into the feasibility of

SPB tanks as LNG fuel tanks.

LNG as fuel

LNG carriers have long been using the

boil-off gas (BOG) from their cargo tanks

as fuel for their engines. In 2000, the

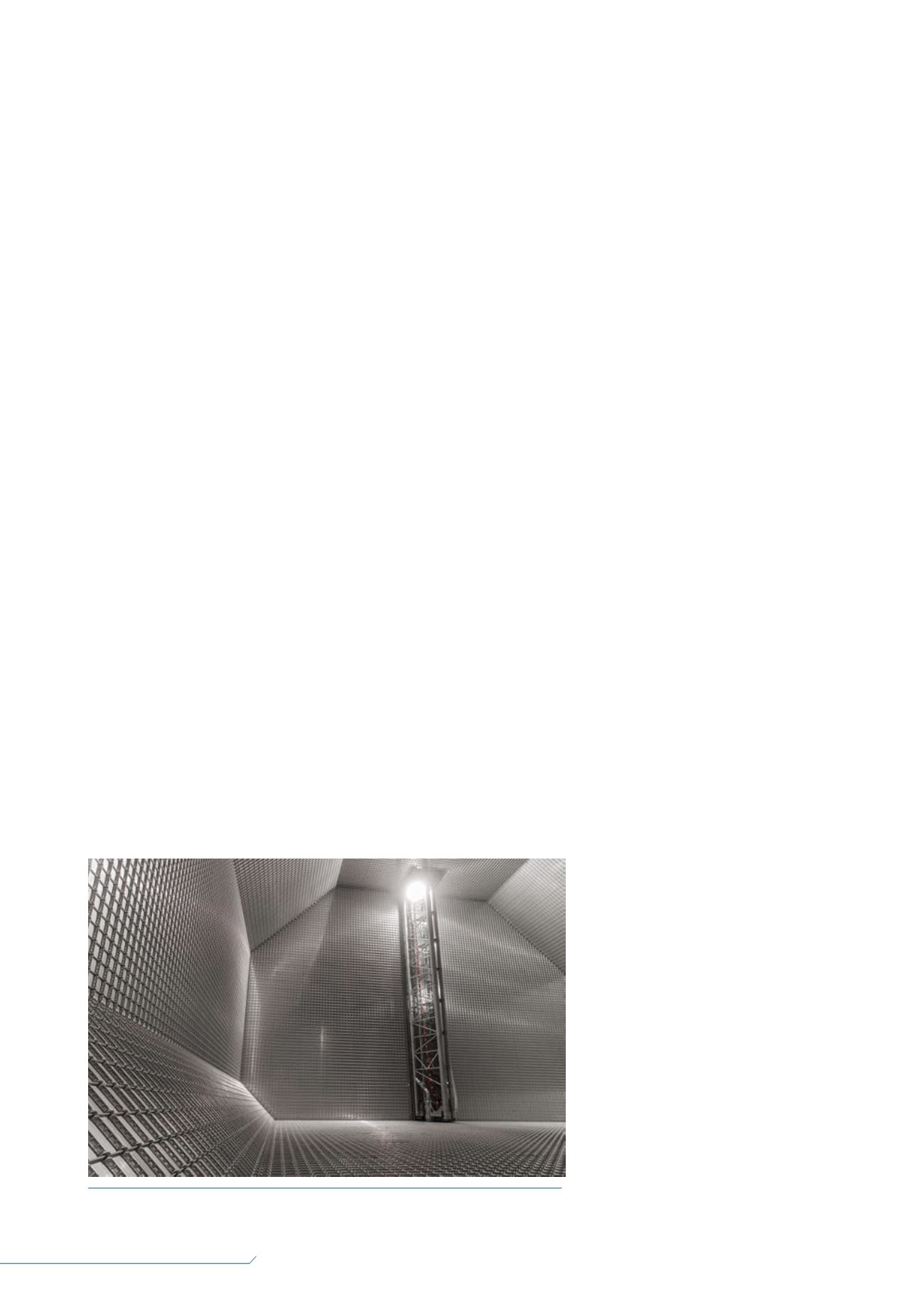

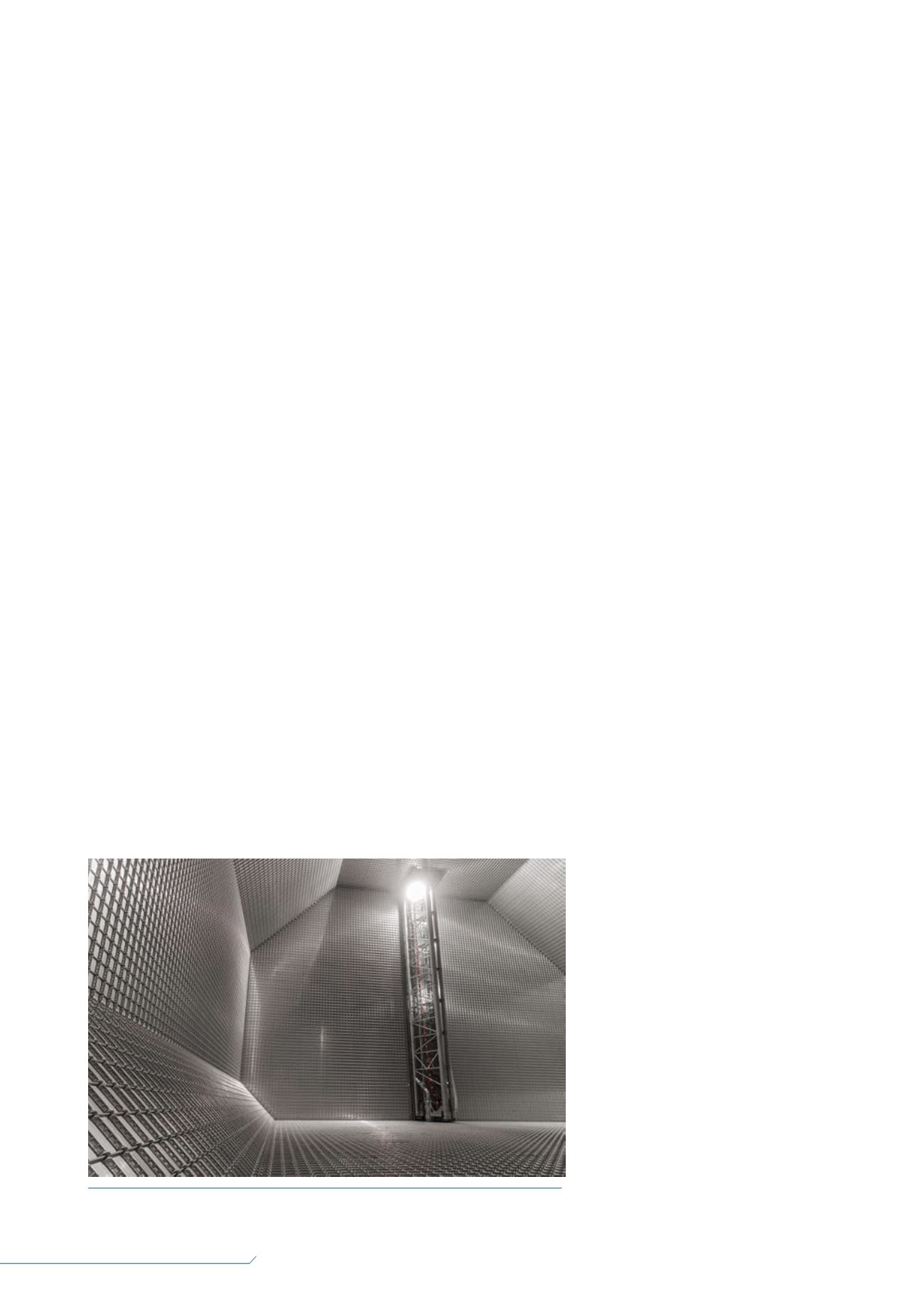

Figure 1.

View of the interior of a Gaztransport & Technigaz (GTT) Mark III LNG cargo

tank onboard an LNG carrier (source: GTT).