90

LNG

INDUSTRY

MARCH

2016

LNG training: engineers

and operations

technicians

This article covers the training structure for gas

production, baseload liquefaction and regasification

terminals. Important characteristics of engineer and

operations training are summarised in Table 1.

Engineering duties are usually medium to

longer term. However, unit contact engineers often

have urgent assignments. Engineering is discussed

later in this article.

In contrast, operating technicians’ work is

usually more immediate. They operate in the

middle of the LNG plant and handle its operation.

Gas processing and LNG

plants

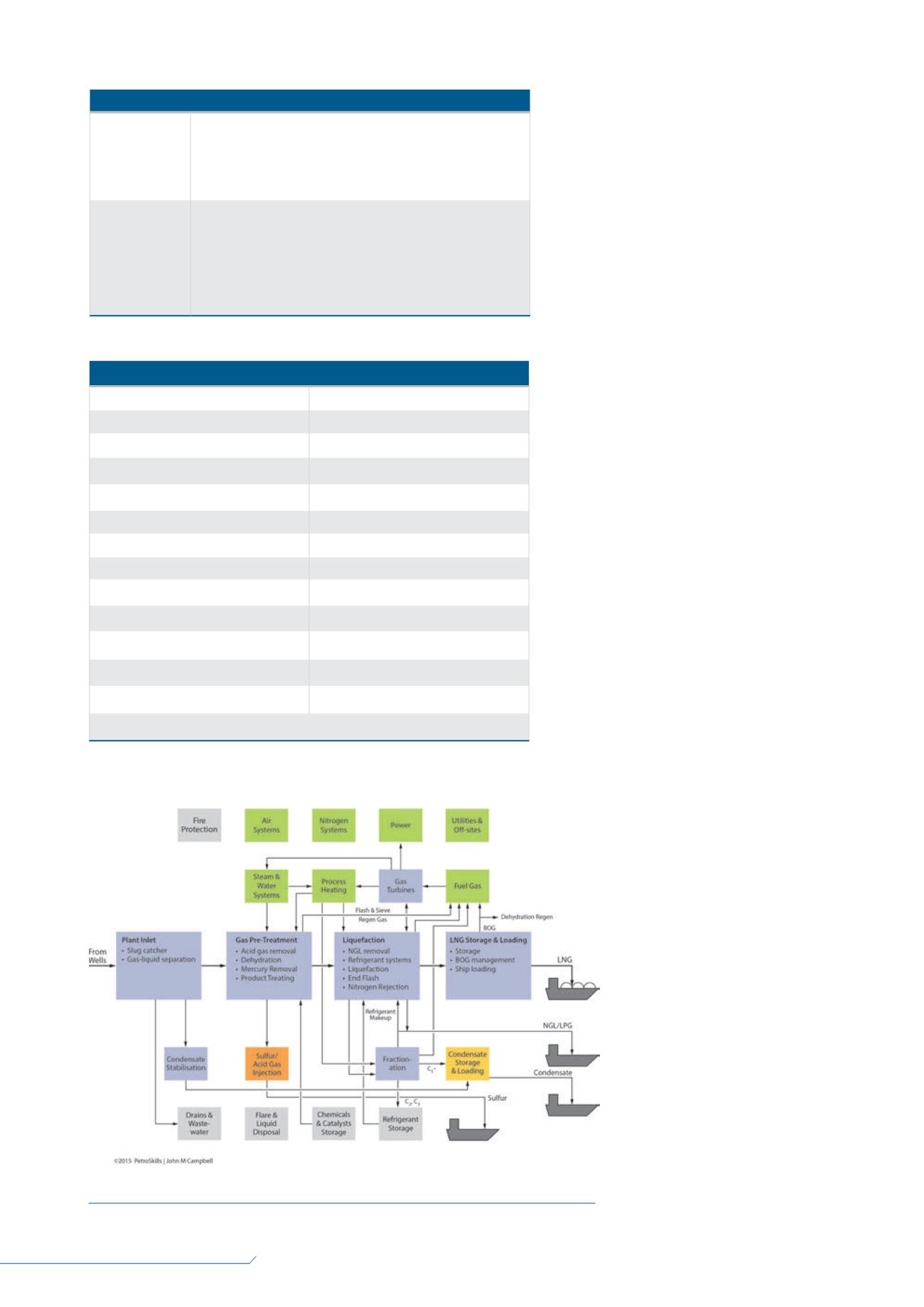

Figure 1 illustrates the main processing and utility

blocks. Baseload LNG plants represent enormous

project management, engineering, procurement

and construction (EPC) challenges. Mostly, they are

large gas processing plants in remote locations.

They involve complex and specialised cryogenic

liquefaction, product storage and shipping.

Furthermore, they contain some of the largest

compressors and other equipment in the oil and gas

industry.

Processes clearly specific to LNG, as contrasted

to the broad range of gas processing, include the

following:

The liquefaction block’s processes handling

mixed refrigerants (MR), and/or ethylene,

methane cycles.

LNG storage and boil-off gas (BOG).

LNG loading and shipping.

The remaining blocks in Figure 1

largely draw upon traditional gas

processing technology. This contrast is

summarised in Table 2.

It is mainly with the liquefaction

processes below, for example, -40°C

(-40°F) that a clear and interesting

specialisation appears. However, the

complex liquefaction technologies are

underpinned by the subcooling and

economiser principles found in

propane refrigeration systems.

This is certainly not to diminish the

technology, sophistication and

complexity of LNG liquefaction,

storage and shipping, but rather to put

them in perspective within the overall

LNG plant facilities.

The new and fast growing mini

and micro LNG plants extend training

needs to an increasing number of

plants with minimum staffing levels.

These all require the basic gas

processing to be correct. They also

introduce a different set of skills

Figure 1.

Main process units of an LNG plant.

Table 1.

Contrasting LNG engineer and operator training

Engineers

More abstract. Some mathematics and applied engineering

principles. Often quite intense. Connect basic chemistry and

physics to how an LNG plant works. Engineering principles of key

equipment including off-sites and utilities. In most cases, learning

is in the office or classroom

Operations

Generally specific to the plant down to equipment numbers

and drawings, flowsheets, equipment data, etc. Practical

demonstrations of scientific and engineering principles. Detailed

‘operation’ knowledge of individual equipment. Context of

the operators’ day-to-day duties. Stop short of valve-by-valve

procedures. Combination of classroom learning with skill

verification and evidence recording in the field

Table 2.

Process technologies of gas plants and LNG units

Mainstream gas processing

LNG processes

Producing wells (offshore/onshore)

Gas/oil/condensate gathering lines

Field dehydration (glycol), etc.

Inlet separation/slug catchers

Condensate stabilisation

Gas sweetening (amine, etc.)

Gas dehydration

–

molecular sieve

Mercury removal

Propane refrigeration

Mixed or cascade refrigeration

Natural gas liquids (NGL) extraction

Cryogenic liquid expanders

LPG storage and shipping

LNG storage and BOG

Nitrogen rejection

LNG shipping

*

*

Shipping of liquefied gases has a long history in certain regions