92

LNG

INDUSTRY

MARCH

2016

related to LNG truck, coastal shipping, and barge cargo loading.

The rapid growth in LNG-fuelled ships requires further training in

LNG bunkering skills, such as hose handling, etc.

What to teach: instructional

design

An alliance of companies has established common course

content for many oil and gas activities. For example, in drilling,

the required competencies are defined and mapped into a

competency management system.

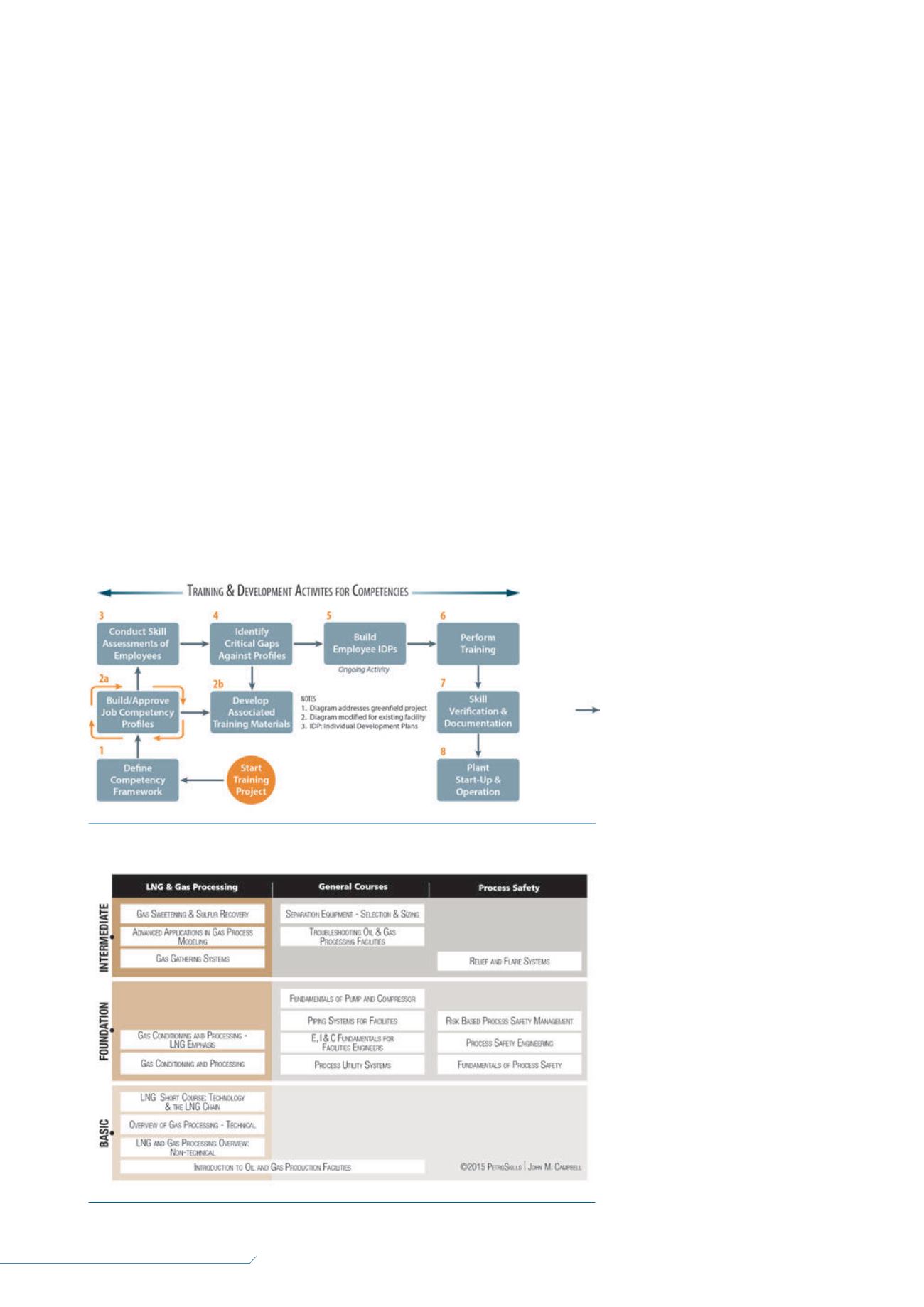

Likewise, in oil and gas facilities, such as LNG plants, there

are established courses and learning programmes to train small

or large groups. Figure 2 shows a simplified training and

development sequence for operations technicians on a

greenfield project. Versions of this sequence can address existing

plants that require a structured training and development

programme.

In Figure 2, the various job roles and positions matching the

organisation chart are identified in Box 1.

Box 2a represents the major effort to define the necessary

skills for each position. Initially, these can be high-level

summaries for each skill/position, but at some point, an

agreed-upon detailed skills list will be needed. The clockwise

series of arrows around Box 2a signifies the iterative nature of

discussions leading to an agreement on required skills. These

skills need documenting. Competency maps (CMAPS) are an

established format for such documentation and will be

discussed later.

Box 2b, coupled with an instructional design function,

defines the required training programme to deliver the required

skills and competencies for LNG plant staff.

The activities in Boxes 3 and 4 culminate in identifying critical

skill gaps in employees. These activities serve to both refine

training materials and also form the basis for employee

individual development plans (IDPs) (Box 5).

The ‘ongoing activity’ note accompanying Box 5 is a

reminder that training and development is an ongoing individual

activity long after start-up. The IDP is a roadmap for the

employee’s future career growth.

Box 6 covers the actual training programme delivery. The

training programme needs careful scheduling to dovetail with

LNG plant start-up.

The important skill verification and documentation in Box 7

should reside in a company’s learning management function.

This systematic approach documents the team’s preparedness

to begin complex operations.

Returning, for a moment, to Box 2a and the documenting

(mapping) of the skills – such maps already exist within the

CMAPS of the 34 companies constituting the PetroSkills training

alliance. In this alliance, a system of curriculum advisors,

discipline managers and subject matter experts create CMAPS

that meet their needs and satisfy their standards. In turn, training

materials are based on these

competencies.

Owner-managed

training

This training is best done as a direct

owner-led activity. This allows the

management structure established

during the training phase to flow into

start-up and operations, producing

continuity and confidence. Why would

an owner want to avoid and neglect

the rapport developed between

trainers and operations just when most

needed during the stress of start-up

and initial operation?

With direct owner-led training, the

operations supervision and

management are already familiar with

the personalities, strengths and

limitations of all operating technicians

and maintenance teammembers at

start-up.

A detailed training programme for

operations technicians should include

separation, absorber, adsorber, and

refrigeration theory from the

perspective of hydrocarbons, both

chemically and physically. Laboratory

settings would also be included where

hands-on experience in a controlled

environment would test the theory and

enforce key learnings.

This is followed by hands-on

training on plant equipment for skill

verification and documentation. This

training is specific to each individual

Figure 2.

Training and development sequence.

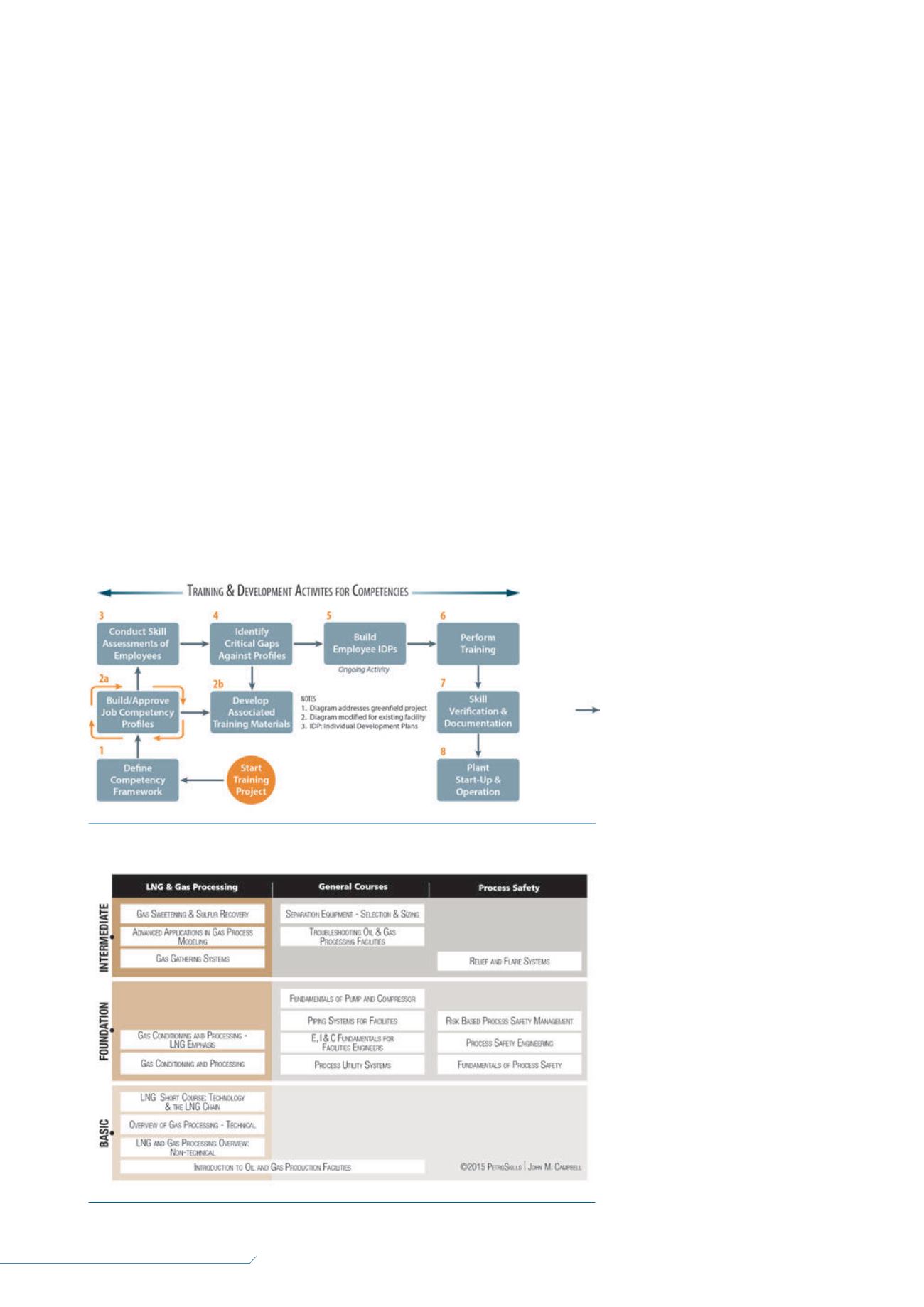

Figure 3.

Example engineering course progression.