96

LNG

INDUSTRY

MARCH

2016

People learn best by doing, especially when they are allowed

tomake mistakes. However, in many situations, a mistake can be

catastrophic. This is why immersive simulation, such as the

modern flight simulator, is so effective. Being able to learn new

skills, or to refresh one’s memory by rehearsing infrequent,

complex or hazardous tasks in the safety of the virtual world,

results in improved safety and efficiency in the real world. Not

surprisingly, therefore, operators are requesting, or even

mandating, immersive training environments for their vessels and

facilities.

Nonetheless, creating such environments is not a trivial

exercise; the virtual vessel or facility must faithfully represent the

real as-operated one. The first need, therefore, is an efficient way

of translating a 3D design model into a simulation environment.

This has been one of AVEVA’s priority developments, so that

today, a model created in the industry-standard AVEVA PDMS™,

AVEVAMarine™or AVEVA E3D™ solutions, can be readily

converted, not just into a passive replica, but into one in which

valves turn, switches switch and objects can be unbolted and

replaced. Ongoing development is now focused on ways tomake

it quicker and easier to keep the simulation model up to date with

the many continual changes that the real facility undergoes

throughout its working life. Looking further ahead, developments

are beingmade to exploit 3D laser scanning technologies to

create andmaintain interactive simulations of facilities for which a

design model does not exist.

There are potential limitations from the sheer size and

complexity of many modern engineering assets. AVEVA’s 3D

design and visualisation technology can support plant or ship

models of unlimited size. As a result, AVEVA AVP has no practical

limitations on model complexity.

In-game project information

Users need to capture functional interactions from the engineering

or design intent and to embed these relationships between

objects in the simulation. For example, in a lock-out/tag-out

scenario, closing a valve or isolating a switch must be reflected

both in any corresponding indicators and in the behaviours

of connected objects. Achieving this requires information

contained in schematic sources to be used, such as piping

and instrumentation design (P&IDs) or single-line diagrams.

Again, manual translation of such information can be costly and

error-prone, so automating this is important both for the original

creation of a simulation and for its long-termmaintenance.

For an effective user experience, it is desirable to be able to

access asset information fromwithin the immersive training

environment itself, rather than having to jump out into other

programs or information sources. Typical examples would be a

drawing, a maintenance procedure for a piece of equipment, or a

P&ID to verify the correct valve to close. In AVEVA AVP, this is

implemented in the formof an in-game browser that can be

opened as required to view any available online information,

simulating the use of a ruggedised tablet device when on site.

What makes this feature particularly valuable is the potential that

it offers for creating structured, interactive e-learning exercises for

operator training.

Immersive training experience

There is considerable interest in the oil and gas industry for the

integration of process simulation with immersive training. This

could increase the realismof many scenarios. For example, an

operation, such as restarting a process or a main engine, could

have the simulated plant behave exactly as the real one would,

with vessels filling at realistic rates, or pressures and temperatures

exceeding safe limits if the restart is fumbled by a trainee

operator. It would also enable better analysis of hazards and

incidents.

The effectiveness of 3Dmetaphors for accessing information

is driving a steady convergence between different solutions. For

example, the newAVEVA Engage™decision-support solution

combines real-time navigation of a complex 3Dmodel with

powerful information management technology to enable a user

to drill down to any level of information about any object.

Furthermore, ‘In Context Technology’ presents directly relevant

object information to a designer or engineer within their design

solution itself. So, one can expect to see immersive training and

simulation also being underpinned with information management

that provides increasingly better access tomore of a facility’s

digital asset. The potential exists to begin creating an

immersive simulation at an early stage of design development

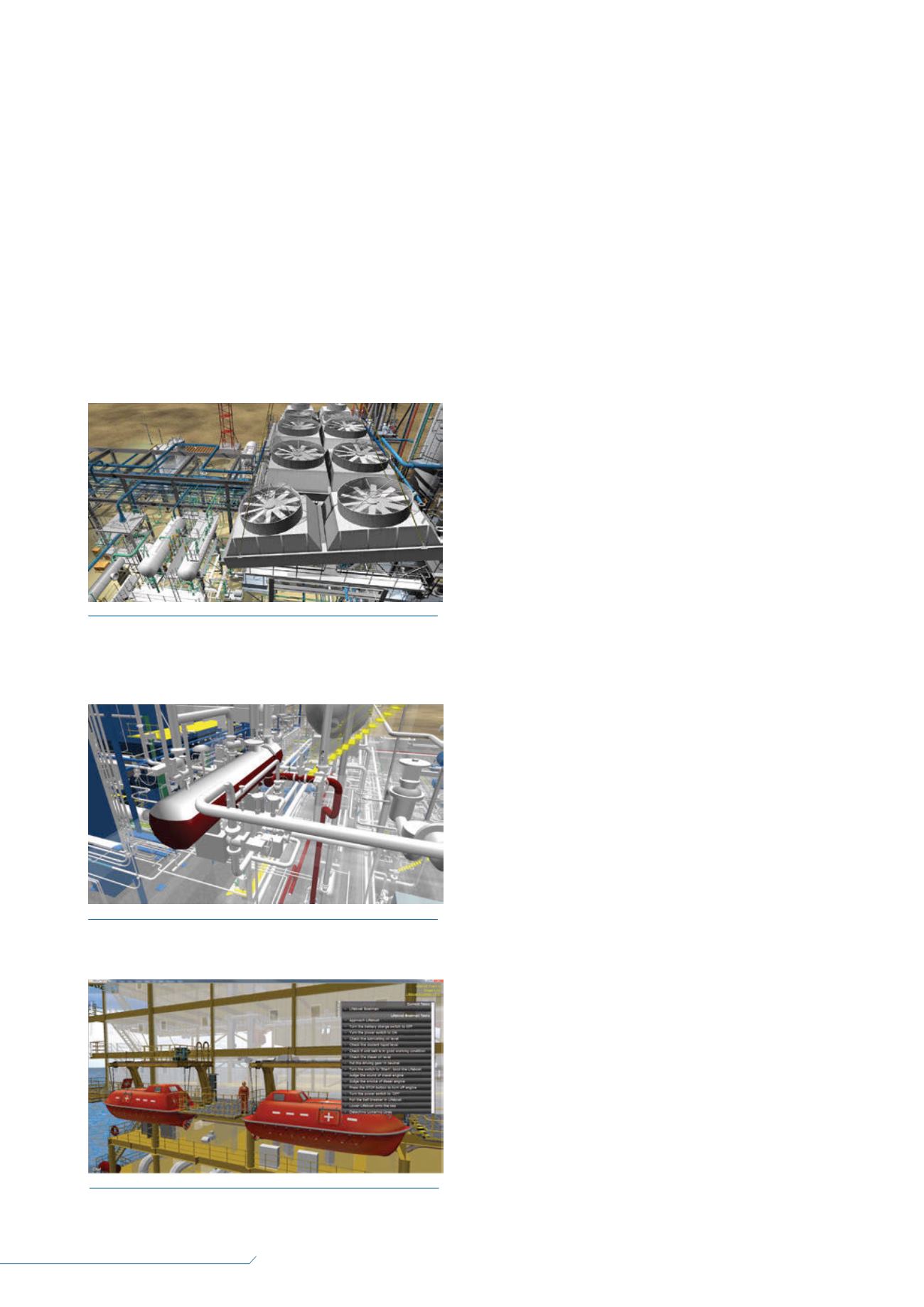

Figure 1.

An illustration from a training exercise in AVEVA AVP.

The realistic objects were created directly from the AVEVA PDMS

3D design model and accurately exhibit properties such as weight

and inertia.

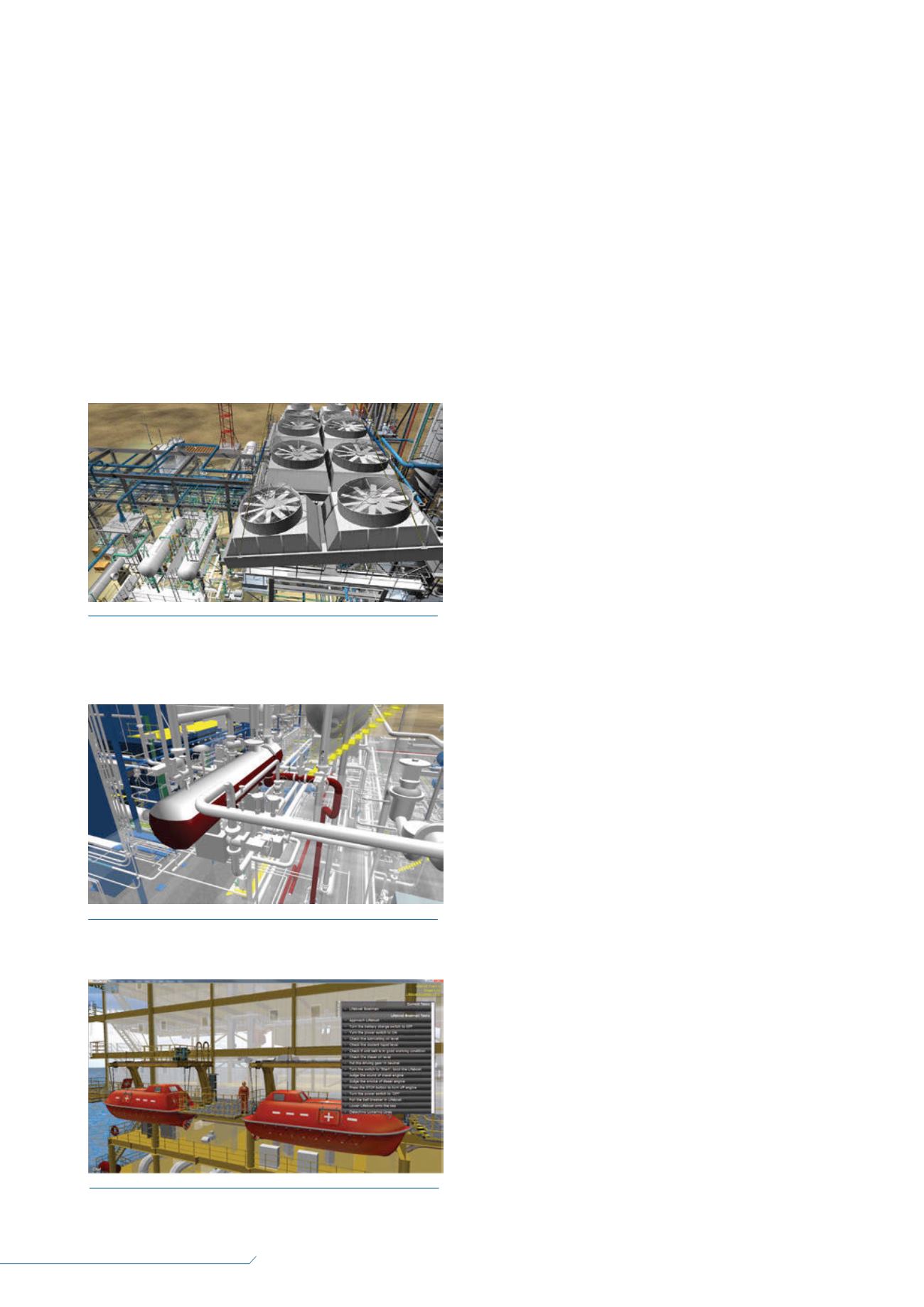

Figure 2.

Process animation in an interactive AVEVA AVP

simulation (model courtesy of CNOOC).

Figure 3.

Rehearsing correct lifeboat handling in AVEVA AVP

(model courtesy of CNOOC).