104

LNG

INDUSTRY

MARCH

2016

but also because the vast majority of machinery data is

uninteresting. One shaft orbit is very similar to the next,

except when problems occur. Therefore, not all vibration

data needs to be saved, but only vibration data that has

changed from the last stored waveform.

This basic idea has existed since the inception of

process historians. It is embodied in the concept of a

deadband, whereby a trend line that is not changing does

not need dozens or hundreds of points stored. It only

needs two points stored, and a straight line drawn

between them. The deadband simply defines how much

change must occur between one point and the next to

recognise it as a new data point, rather than just a linear

extrapolation of the previous data point.

Initially, the primary imperative for deadbands around

process historian points was the limited storage space of

most computers. In the 1980s, when historians were

beginning to debut, a large hard drive was 20 – 40 MB.

Clearly, the ability to store data efficiently was

paramount, and the sophistication of deadbands and

other compression algorithms were likewise paramount.

In a day when a 1 TB drive can be purchased for less than

US$100, it is tempting to think that compression is no

longer that important. There is some merit to this, but

anyone who has ever had to move that 1 TB across a

network will understand that although there is room to

store all of the data, it can take a long time to move it.

Deadbands have historically been used with scalar

data that can be characterised by amplitude and time

tags. However, the concept of only saving data when

something changes can apply to any type of data. It is

now routinely being used by the SETPOINT system to

decide which vibration waveforms to keep and which

ones to ignore.

Consider a shaft turning at 6000 RPM

(100 revolutions/sec.) on a typical compressor train in an

LNG plant. Additionally, assume that the vibration is

sampled 128 times per revolution for 16 shaft revolutions

(waveform consists of 2048 samples with

78 microseconds between each sample). When the

system first turns on (and assuming the machine is

already running at steady-state speed), it stores the

waveform corresponding to those first 16 shaft

revolutions into the historian as a time series, just as with

any other time series data, but with microseconds

between the values rather than seconds, minutes or

hours. It then examines (but does not necessarily store)

the next 16 shaft revolutions (revolutions 17 – 32). It

examines multiple attributes of the waveform, such as

overall amplitude, gap voltage, frequency content, period

(machine speed), etc., and compares these to similar

attributes of the initial 16 revolutions already stored. If

things have adequately changed, it also stores the new

waveform. If things have not adequately changed, it only

keeps the first waveform and discards the other. The

system continues on in this way indefinitely, collecting

and examining every waveform, but only saving those

that represent sufficient change from the baseline. This, in

essence, is how the deadbanding of waveforms, rather

than just scalar data, is accomplished.

By utilising the concept of a deadband for not only

conventional trend data, but also for high speed

waveform data, the system is able to continuously collect

and analyse every waveform from every rotation of the

machine’s shaft. However, it only stores this data when a

waveform has sufficiently changed relative to its

constantly updating baseline. The system can, therefore,

go for long intervals without saving extraneous

waveforms if conditions are not changing, yet store

waveforms quickly when conditions are rapidly changing,

such as during machine start-ups, process upsets, or

incipient mechanical failures. Therefore, two years of data

from a typical 300-channel system only requires a modest

1 TB of storage space, employing a combination of

compression algorithms native to the process historian

and new algorithms for high speed waveform data.

Boost mode

Some machines can exhibit extremely fast starts

and stops, such as motor driven pumps and smaller

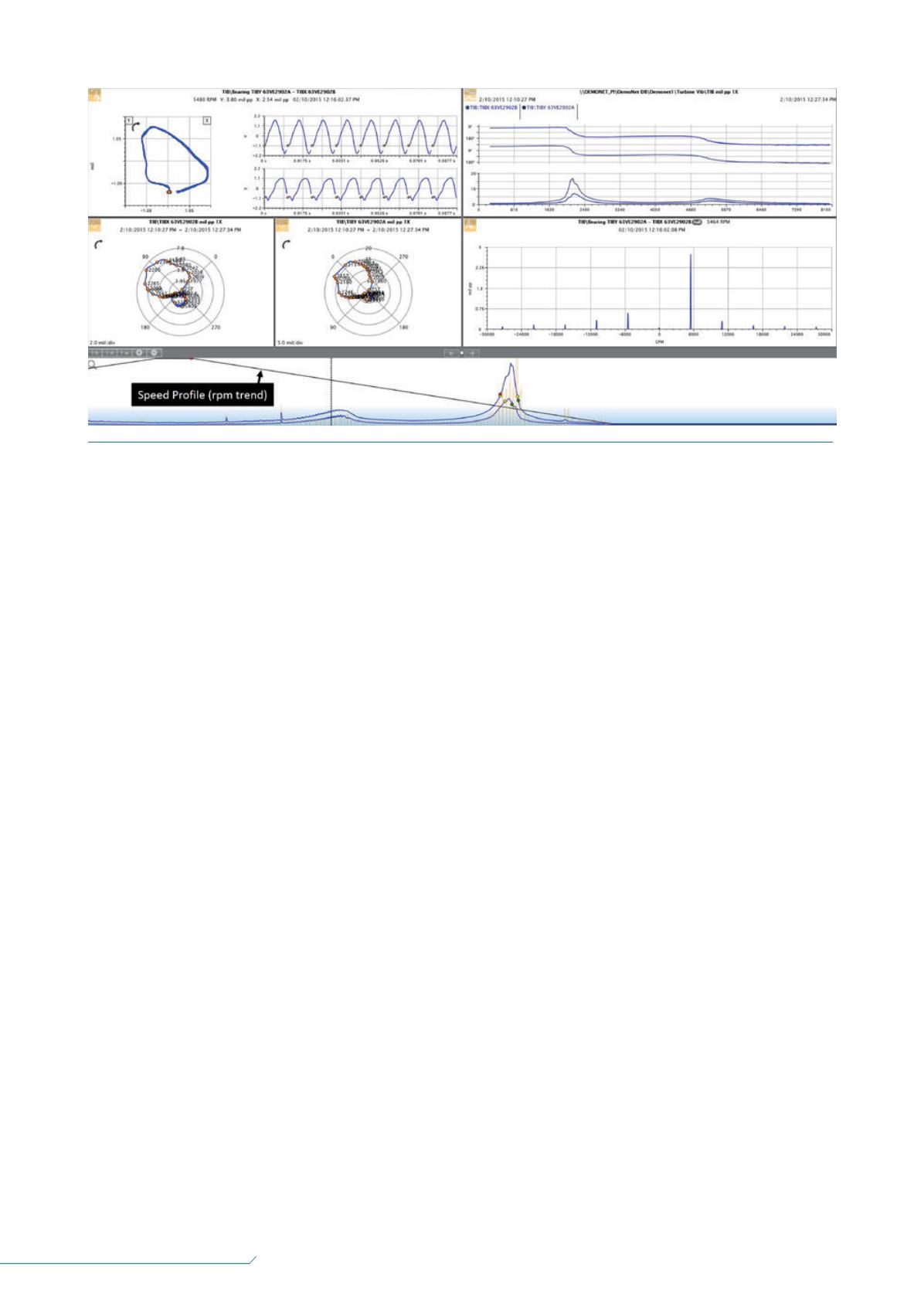

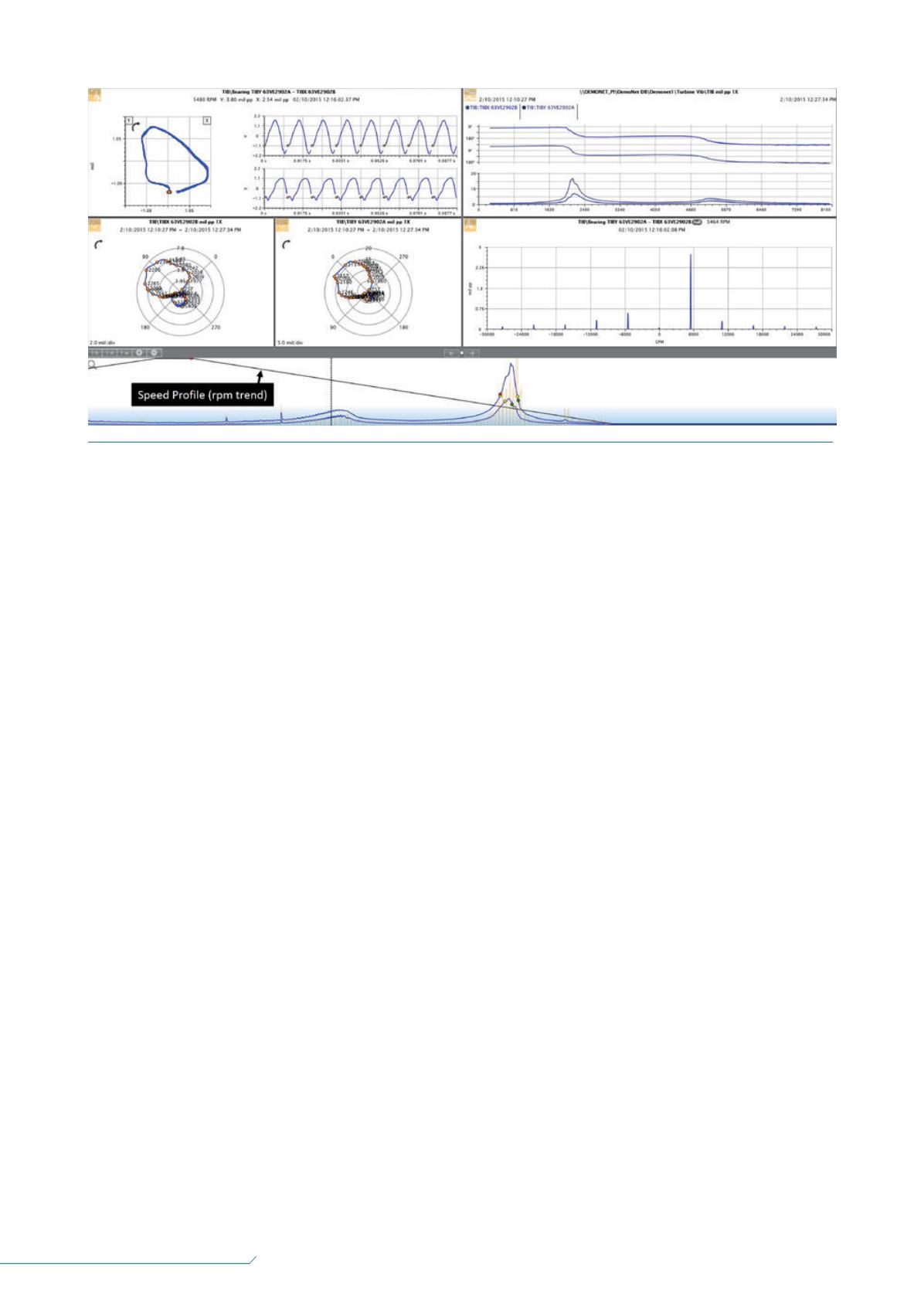

Figure 5.

Waveform data collected during a machine trip.