110

LNGINDUSTRY

MARCH

2016

PREVIEW

Air Products -

Stand 1284

A

ir Products is a leader in natural gas liquefaction

technology. Its experience extends from plants

producing less than 0.1 million tpy of LNG to

the largest baseload plants in the world using the new

AP-X

®

LNG process. Its MCR

®

main cryogenic heat

exchangers and natural gas liquefaction processes offer

reliability, high efficiency, and operational flexibility. In

addition, the company’s equipment has been selected

for the world’s first floating LNG (FLNG) facilities. With

over 45 years of LNG experience, Air Products has built

more than 100 LNG heat exchangers for customers in

16 countries worldwide.

Air Products’ 20 000 employees serve customers

worldwide with a unique portfolio of atmospheric,

process and specialty gases, performance materials, and

equipment and services. It is recognised for its

innovative culture, operational excellence and

commitment to safety and the environment.

Air Products has sales of US$10 billion and operations in

over 50 countries.

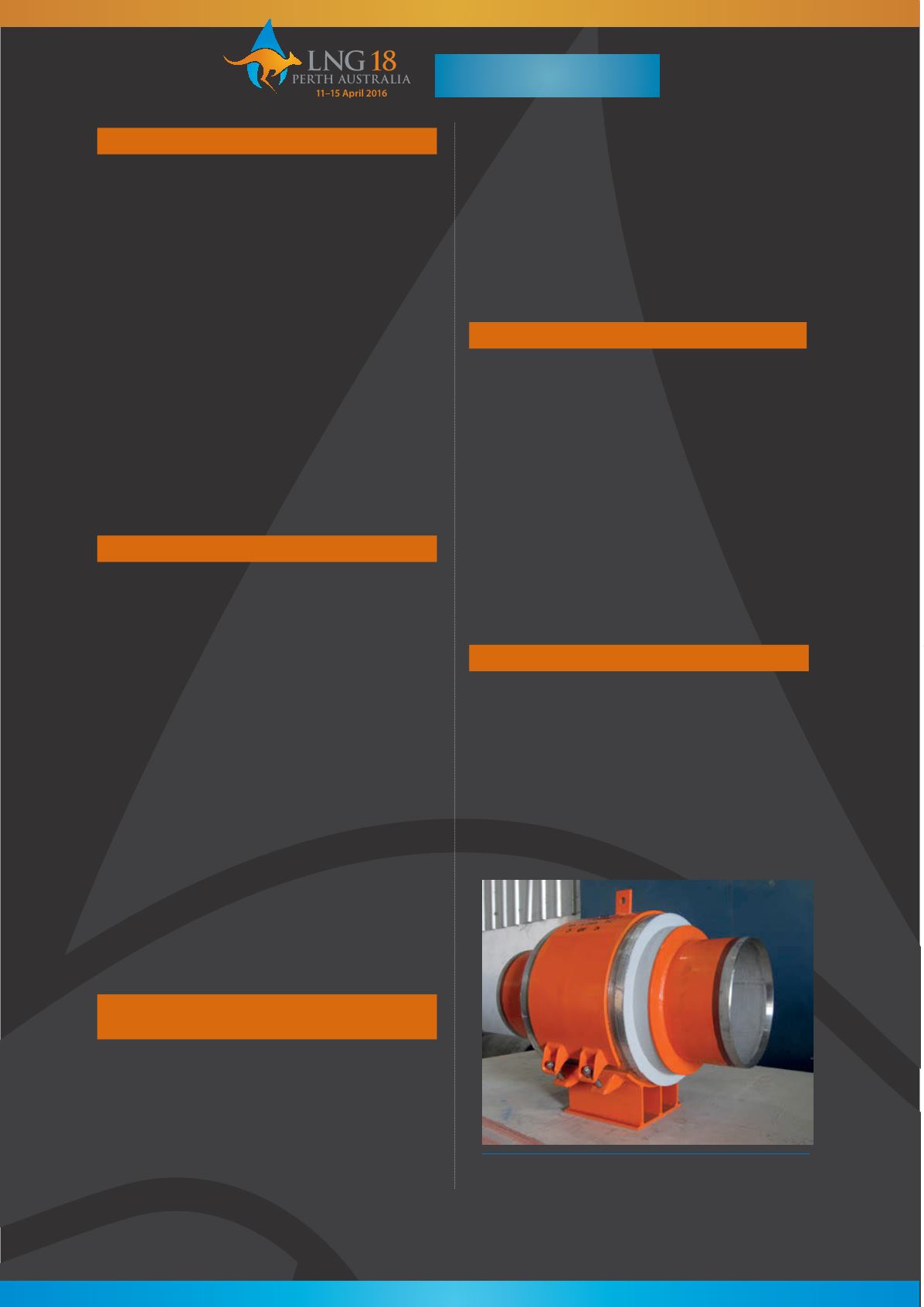

A cryogenic pipe support from Bergen Pipe Supports.

Black & Veatch -

Stand 1110

B

lack & Veatch is a global leader in the planning,

design, procurement, turnkey construction

and modification of LNG production (offshore/

onshore), LNG import and export terminals, ammonia/

fertiliser, sour/rich gas processing, sulfur recovery, and

gasification facilities. Its global leadership stems from

decades of proven performance on more than 3000

assignments in over 40 countries. It maintains its position

by pioneering technologies and providing innovative

solutions. Large complex project execution capabilities

BESTOBELL VALVES -

Stand 1300

P

arker Bestobell Marine will be launching its new

range of high pressure marine valves for fuel gas

systems at LNG 18.

The company will also be demonstrating its new

compact Float Level Isolation Valve (FLIV) at LNG 18. The

FLIV was developed to cater for the use of smaller

diameter floats that are now being specified by

shipyards for secondary level monitoring systems on

LNG carriers.

Parker Bestobell Marine’s valve technologies are

widely used on LNG carriers, FLNG units and FSRUs. The

company designs and produces valves to meet specific

requirements in the marine sector and has supplied

cryogenic valves to a majority of the major shipyards

building LNG carriers.

BASF -

Stand 1000

B

ASF will present solutions for the oil and gas

industry in the fields of natural gas treatment with

a focus on OASE

®

purple, OASE yellow and OASE

secco technologies, as well as Sorbead

®

technology at

LNG 18.

Under the OASE brand, BASF provides customised,

high performance gas treatment technologies for use in

traditional applications, such as syngas and ammonia,

sales gas and LNG facilities. BASF’s gas treatment

process requires lower energy input, reduces corrosion in

LNG plants and delivers high plant availability. OASE

solutions have been proven and demonstrated in over

400 reference plants globally.

Moreover, BASF offers a broad range of excellent

technologies and solutions based on the appropriate

absorbent (solvent), adsorbent and catalyst. It also

supports its customers with respect to process design,

engineering support and a wide range of technical

services. Products such as Sorbead alumino-silica gels

and molecular sieve adsorbents meet the requirements

of the highly complex natural gas treatment industry. The

adsorbents are successfully utilised in gas and fluid

purification, separation and drying processes.

Bergen Pipe Supports -

Stand 1191

B

ergen Pipe Supports is a leading global supplier

of insulated pipe supports to both onshore and

offshore liquefaction and regasification plants.

With over 15 years of designing, developing and

manufacturing cryogenic pipe supports for LNG

applications, combining optimum insulation, isolation

and strength characteristics, Bergen now manufactures

over 3500 t of high density polyurethane foam (HD PUF)

insulated pipe supports every year with plants in

Thailand and the US.

With test facilities to satisfy compliance with

ASME/ASTM and CINI thermal insulation standards, and

full 3D modelling, product identification and selection

software, the company is at the forefront of the

cryogenic pipe support industry and has the commercial

and technical team to deliver an excellent cryogenic pipe

support solution.