106

LNG

INDUSTRY

MARCH

2016

compressor trains and blowers driven by motors or steam

turbines. On such machines, the transient conditions can

be brief and the ability to store every waveform, as with

an analogue tape recorder, can be important. Normally,

the system will save no more than one waveform from

each vibration sensor every 2 – 3 sec., and it simply

chooses the most interesting waveform during that

interval. If nothing is interesting, then nothing is saved.

The system, therefore, can go for many minutes or hours

without the need to save anything. However, during fast

starts or stops, the system can be placed into a special

mode in which every single waveform is saved for the

duration of the start-up or shutdown.

Operating experience

Experience gained over the last two years has

demonstrated that a commercial process historian,

namely the OSIsoft PI System, is capable of handling

vibration data without constraining the types of plots,

data resolution, or features that are required by rotating

machinery engineers and vibration analysts. By using

the process historian as the single ‘system of record’

for not just process data, but also for vibration data and

compressor surge/thermodynamic performance data,

the ease of correlating process, vibration, and other

relevant machinery information is greatly facilitated and IT

infrastructure is eliminated (Figure 3). Indeed, the identical

considerations discussed in this article for vibration data

and its special needs can (and are) being extrapolated

to compressor surge/thermodynamic performance data,

so that it too can use the process historian rather than

necessitating a separate ‘silo’ just for its own data.

Vibration data is stored in the process historian as

time series and event records, just as any other process

data, and can be visualised using standard process

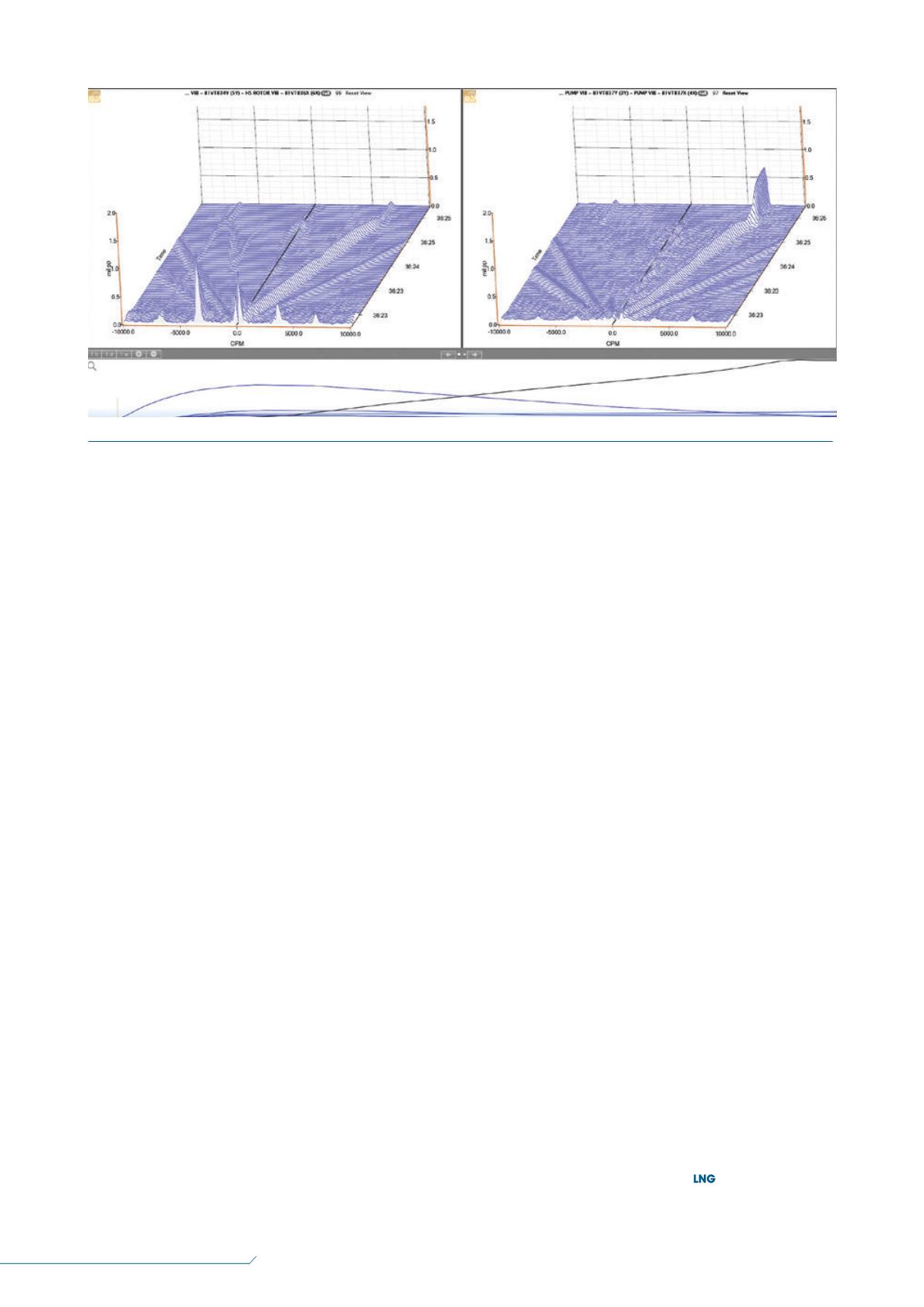

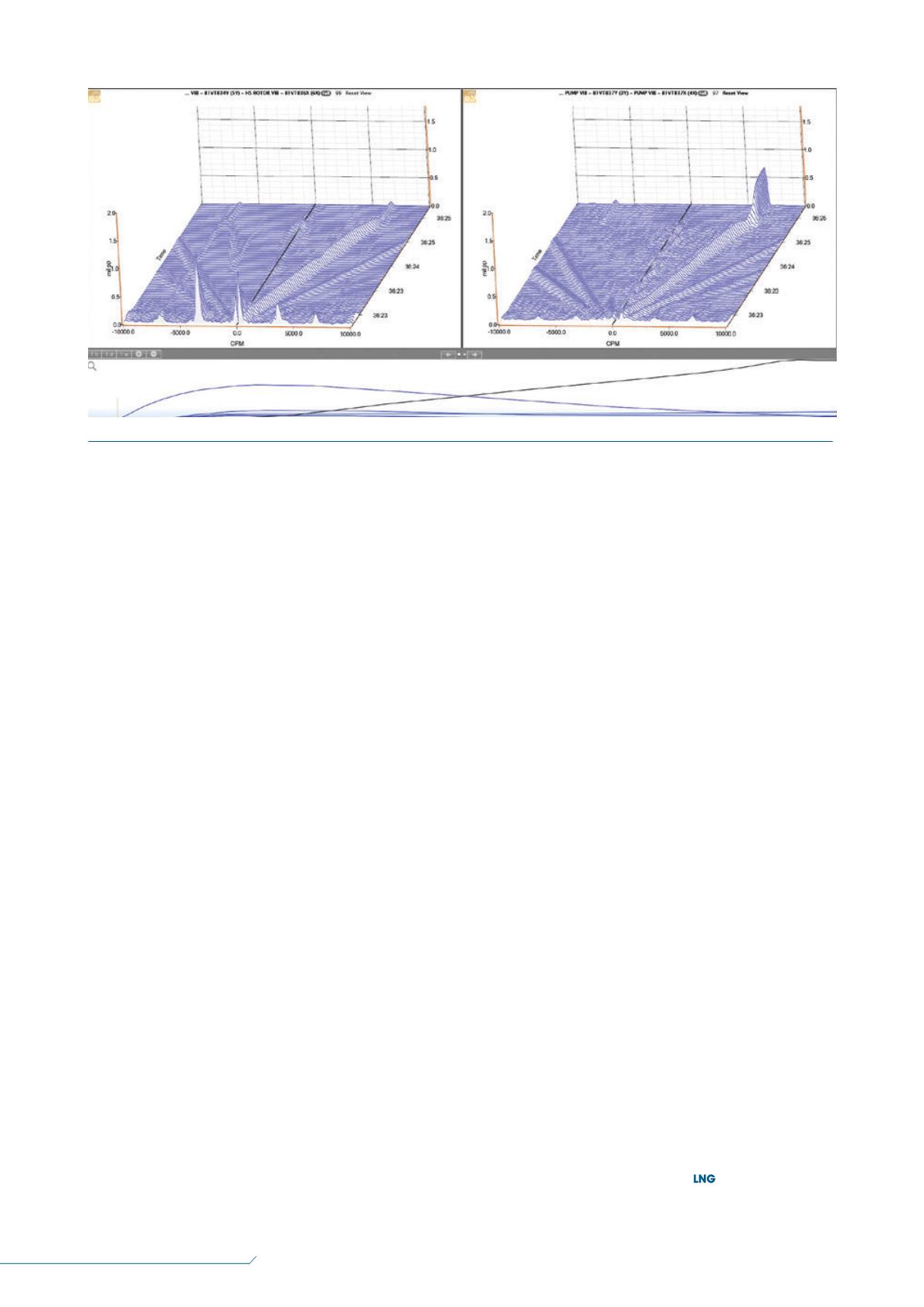

historian tools, such as PI ProcessBook (Figure 4). When

users need to access more specialised plot types that are

not native to the process historian, a separate

visualisation tool is used. Its purpose is simply to display

the vibration data resident in the historian that cannot be

presented using standard trends, bar graphs, and other

tools native to the historian. Examples of the vibration

visualisation tool are shown in Figures 5 and 6.

The system described here is in use at more than

two dozen sites globally, many of which did not require

the purchase of any additional software as they were

already users of the OSIsoft PI System and had the

requisite number of tags and server capacity to add the

desired vibration data.

Conclusion

The industries in which critical machinery is used, and

in which continuous vibration monitoring is practised,

have conditioned themselves to accept the necessity

of separate databases and tools for each kind of data,

be it process data, vibration data, thermodynamic

performance data, or compressor surge data. The

historical reasons for this have largely been technical

in nature, due to the limitations of process historians.

However, advances in the speed at which the historian

can write data to its database and in the data structures

it uses have removed the impediments to the inclusion

of vibration data, including the extremely high speed

waveform data necessary for machinery engineers and

vibration analysts to perform their jobs. The benefits

of using a single system extend not only to these

individuals, but also to corporate IT departments that

want to standardise and rationalise the number of

software platforms used across the enterprise, while

simultaneously providing high levels of reliability and

security. As the process historian is almost always

considered a ‘mission critical’ application with a broad

base of users and IT support resources, the inclusion

of other types of data, which has previously been

impractical or impossible – such as vibration and surge

data – is now a viable alternative.

Figure 6.

Electric motor driven start-up lasting only 3 sec.