48

LNG

INDUSTRY

MARCH

2016

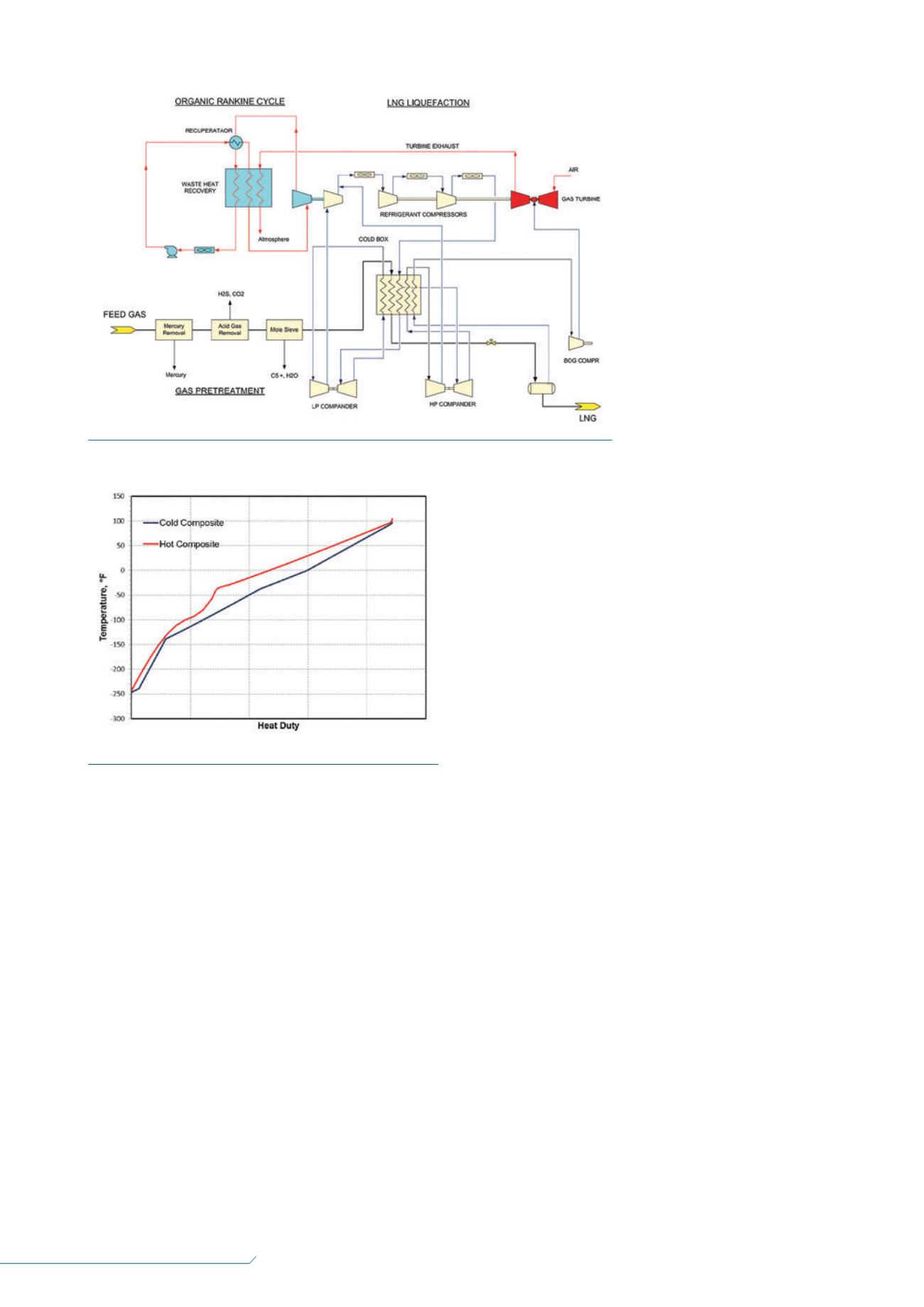

Integration to SMR

liquefaction cycle

The configuration of the SMR cycle

1

has been integrated

with the ORC power plant as shown in Figure 1. As described

previously, the high pressure lean gas is treated and dried,

with its C

5+

content removed in the molecular sieve unit. The

treated gas is chilled, condensed and subcooled in a cold box

to approximately -245°F using refrigeration produced by the

SMR cycle. The cold box uses a multi-pass brazed aluminium

heat exchanger to produce a subcooled LNG and refrigerant

at high pressure. The high pressure subcooled refrigerant is

let down by the Joule-Thomson effect and chilled, forming

the cooling medium for the liquefaction process. The high

pressure subcooled LNG is then letdown in pressure to close

to atmospheric pressure for LNG storage. The flashed vapour,

or boil-off gas (BOG), is heat exchanged in the cold box for

recovery of the refrigeration content prior to being used as fuel

gas to the gas turbine. To improve cycle efficiency, a hydraulic

turbine can be used for recovery of power and refrigeration.

The SMR cycle uses a single working fluid composed of

multiple hydrocarbons and nitrogen. The selected refrigerant

composition depends on the feed gas composition and the

liquefaction pressure. Refrigerant

composition is chosen so that it

has an evaporation curve that

matches the cooling curve of the

natural gas with minimum

temperature difference. A small

temperature difference reduces

entropy generation and, therefore,

improves thermodynamic

efficiency and reduces power

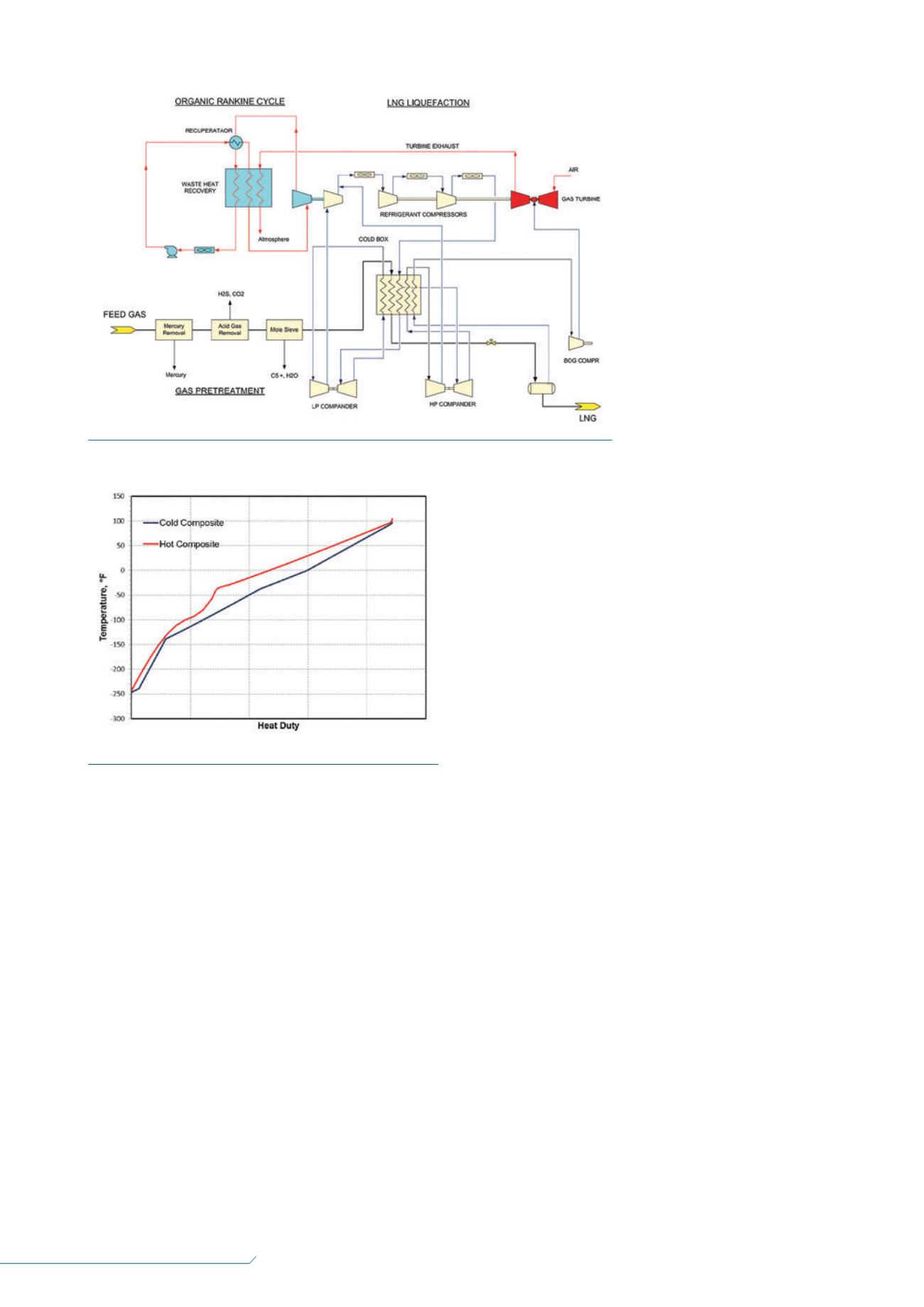

consumption. As shown in

Figure 2, the hot composite

(natural gas) and the cold

composite (SMR) heat curves can

be matched closely, particularly in

the condensing and subcooling

section of the exchanger.

The SMR compression system

typically uses three compression

stages with inter-stage coolers,

with the first stage driven by the

expander in the ORC plant.

Depending on the refrigerant composition, some of the

butane and pentane components will be condensed in the

inter-stage that must be removed before further compression.

The condensate is removed in a separator and pumped to

feed the heat exchanger. Since the air cooler is designed for

summer operation, the outlet temperature will drop during

winter operation, which will result in excessive condensation.

The SMR cycle air cooler must be controlled using variable

speed fans, and in extreme cold weather, some of the air fan

motors must be shutdown to avoid over cooling.

Operation of the SMR requires operator attention. The

process requires a supply of different hydrocarbons and

nitrogen. The refrigerant composition must be monitored and

adjusted to maintain high efficiency, particularly when the

feed gas composition changes.

Integration to expander

liquefaction cycle

While the SMR process is an efficient liquefaction process,

the liquid hydrocarbon inventory in the system is a potential

hazard for offshore applications. The gas-phase expander

cycle, which has been used for small LNG plants and BOG

liquefaction, is a viable option. With the recent advances

in expander and compressor technology, coupled with the

improved process configurations, the thermal efficiency of the

gas expander cycle is close to the SMR process.

The gas expander cycle efficiency is a function of the

compressor power consumption and the expander power

generation. Expander efficiency of over 86% is now common,

and compressor efficiency of over 80% is also available.

Ambient air temperature is another parameter that impacts

the expander cycle efficiency. In cold climate operation, the

compressor suction temperature can be lowered, which

reduces the compression horsepower. On the other hand, hot

climate operation raises the compressor suction temperature,

which increases the compression horsepower. The cold

climate operation cycle efficiency can be 10 – 15% higher than

the warm climate operation.

The expander cycle is a reversed Brayton Cycle that uses

gas expansion to generate power to operate the refrigeration

Figure 3.

ORC and expander LNG liquefaction.

Figure 4.

Composite heat curves for expander process.