44

LNG

INDUSTRY

MARCH

2016

This is opposed to conventional onshore terminals where there

is usually a split between supply of the offloading equipment

and aftermarket services.

From side-by-side to tandem

systems

Operation of offshore gas fields in harsh environments, as

well as the flexibility to relocate an existing FLNG vessel

to any location in the world, naturally led FLNG project

owners to look at LNG tandem offloading as a natural way to

offload oil from a floating production storage and offloading

(FPSO) unit. Previously, the lack of maturity of LNG tandem

offloading technologies proved problematic, but the latest

developments made on the FMC Articulated Tandem Offshore

Loader (ATOL), in partnership with oil and gas majors, dynamic

positioning (DP) suppliers and LNG carrier operators, make

such operations possible.

The FMC ATOL has not only been validated through

comprehensive kinematic, stress and fatigue analysis to

confirm a 99+% operability in the harshest Australian type

conditions, it has also been fully validated thanks to a one-fifth

scale model, tested under the harshest environmental

conditions with third party involvement.

Field-proven component design and technologies from

onshore LNG loading arms, as well as offshore side-by-side

LNG transfer with loading arms, are transposed to the ATOL

LNG tandem transfer solution and were prototype-tested to

real project conditions. For instance, the FMC ATOL swivel

joint successfully passed a long life test equivalent to a 10-year

maintenance-free period (considering one offloading per

week). In addition to this, a consolidated execution plan has

been developed detailing a 24 – 30 month delivery time,

including project specific engineering, purchasing, construction

and tests. As part of this execution plan, the FMC ATOL

emphasises the turnkey approach, minimising the integration

works duration on the FLNG unit to a strictly limited number of

mechanical and electrical interfaces. This all-in-one design

allows for extensive tests to be performed on the ATOL before

its delivery, inclusive of functional, static and dynamic tests

and simulations of emergency disconnections.

Comprehensive engineering studies and compliance with

the stringent expectations of offshore conditions, as well as

the full operability of the offloading system, must be

considered to maintain the performance levels. This requires

the operators to be trained to operate in a safe and

appropriate manner, and to maintain the equipment in fully

operable conditions by performing inspection and

maintenance as required.

LNG bunkering operations

Offshore offloading systems for both side-by-side and tandem

configurations are designed to deliver three main objectives

– the safety, reliability and performance of the operations.

The same objectives are also considered for LNG bunkering

operations, but are realised in a different context. LNG bunkering

is at a junction between conventional fuelling and LNG transfer,

and involves users who are unfamiliar with LNG handling and

transfer. Any major incidents/accidents will dramatically impact

the full LNG chain and market. Therefore, it is important that

LNG specialists are involved to ensure the market’s safe and

sustainable development, and to maintain the LNG industry’s

outstanding safety record achieved over the past 50 years.

LNG bunkering infrastructures are developed to supply

LNG-fuelled vessels, either from shore bunkering stations or

bunkering vessels. Loading arm technologies offer numerous

benefits, including the following:

Safety: based on rigid pipes resistant to fire, together with

field proven swivel joint technology, the loading arms are

associated with an ESD management system, allowing

disconnection in a quick and safe manner, mirroring

conventional LNG transfer.

Flexibility: depending on the range of LNG-fuelled vessels

to be bunkered, the offloading systems can be adapted to

cope with a wide or narrow operating envelope.

Operability and maintenance: rigid pipes offer limited

pressure loss and higher flowrate capabilities. In addition,

the ability to quickly drain the loading arm, or to maintain

it at cold temperature, saves time between bunkering

operations and increases the offloading frequency.

As each project is different, customised offloading

solutions are an excellent approach for a cost-effective

outcome. The design of the first LNG bunkering loading arm

was based on this. The bunkering vessel will be operated by

Shell in the port of Rotterdam, the Netherlands.

Conclusion

Safety, reliability and performance are essential considerations

for the design of onshore terminals, FSRUs, FLNG vessels

or LNG bunkering stations. A maintenance programme is

essential to maintain these three factors during the lifetime

of an offloading system. As each application and project are

different, the design and operation management programme

should be customised to reflect their particular specifications

to provide the most effective CAPEX and OPEX.

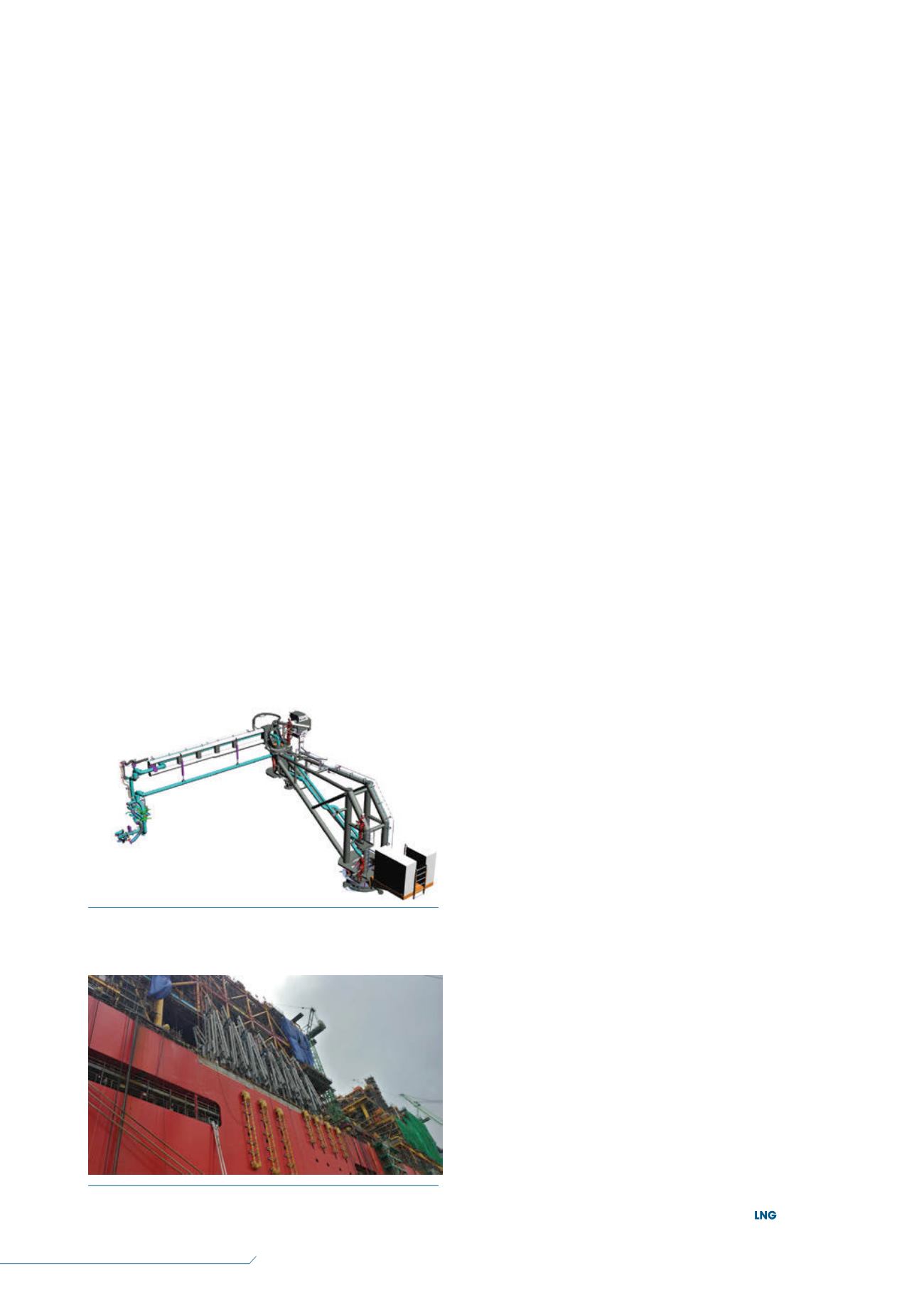

Figure 4.

OLAF offshore loading arms installed on Shell’s

Prelude

FLNG facility.

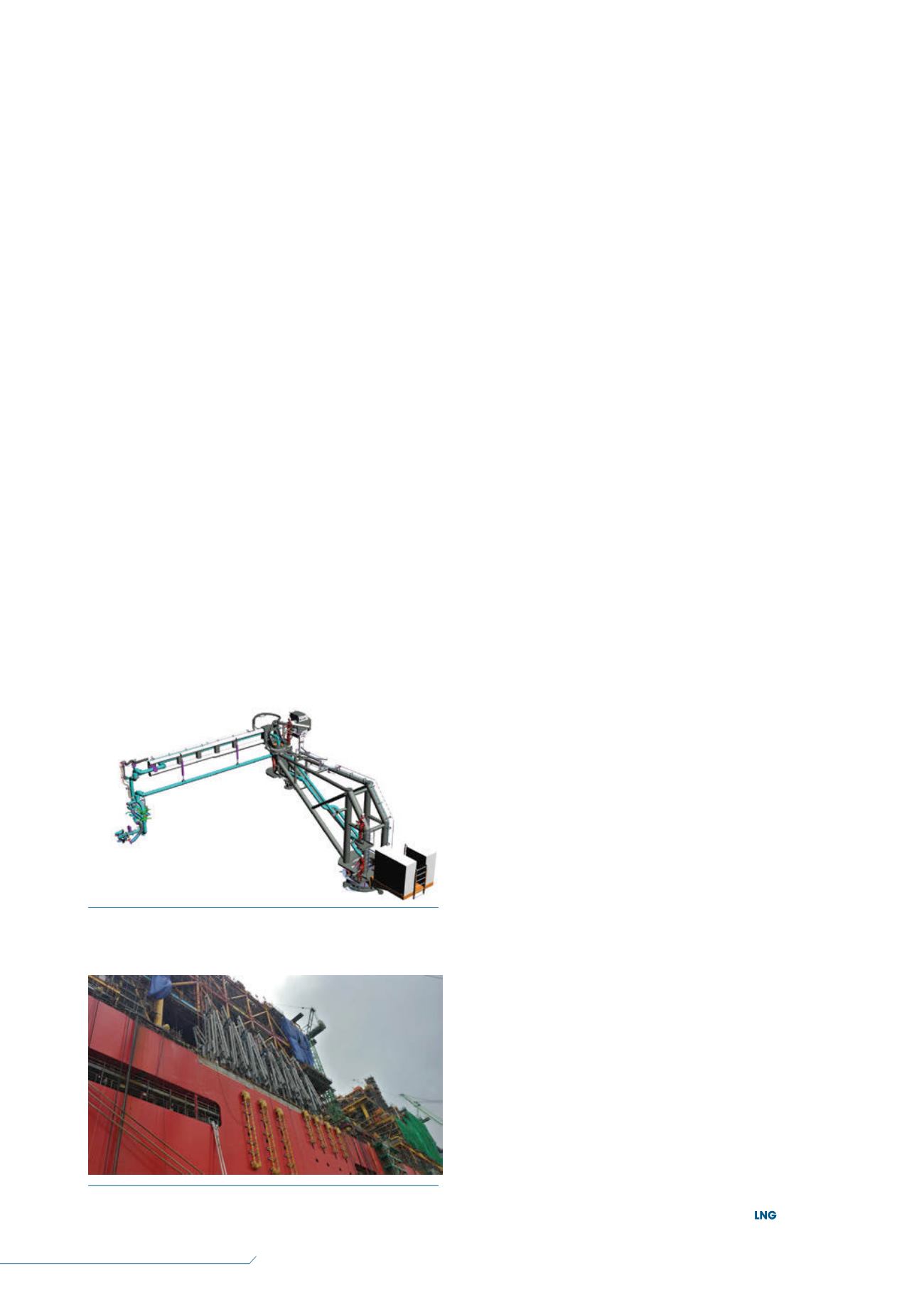

Figure 3.

LNG bunkering arm installed on a vessel.