46

LNG

INDUSTRY

MARCH

2016

Small and mid scale liquefaction facilities typically utilise

simpler refrigeration systems than large baseload facilities

using single mixed refrigerant (SMR) or gas expander (using

nitrogen, methane or a mixture of both) processes. The mixed

refrigerant (MR) cycles are typically more energy efficient,

whereas the gas expander cycles are simple and robust.

For plants using gas turbines to drive refrigeration

compressors, waste heat is typically recovered by either hot

oil systems and/or steam generation to supply heat and/or

power in the LNG complex. Steam generation can be

complex and costly for smaller plants. Small to mid scale

LNG plants can be lower in thermal efficiency and higher in

carbon emissions per unit of LNG produced, relative to

world-scale facilities.

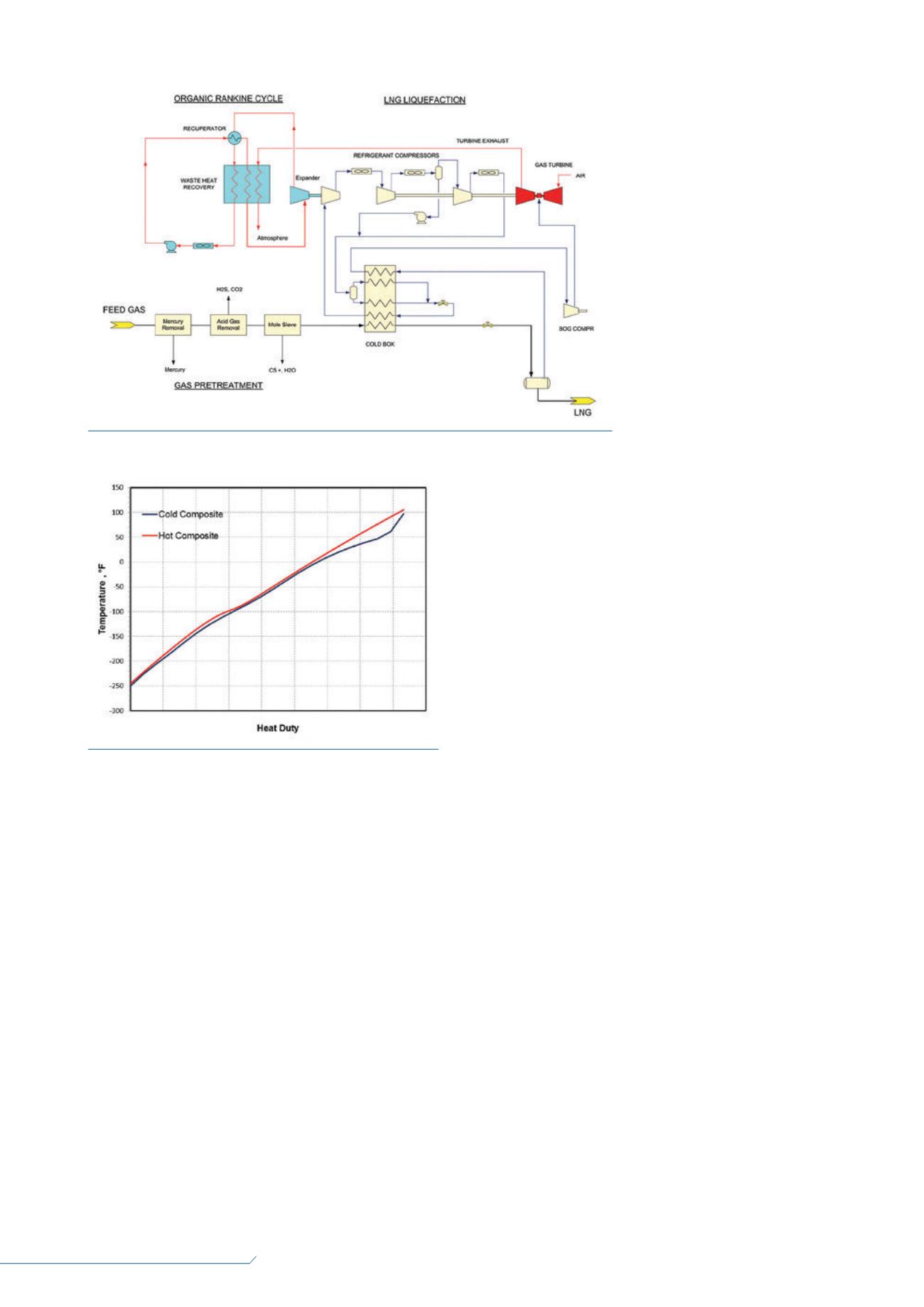

The Organic Rankine Cycle (ORC) is a thermodynamic

cycle based on the classic Rankine cycle using an organic

working fluid. ORC power plants have been proven in

geothermal applications for power generation, but have not

been applied to LNG liquefaction plants. Fluor has developed

small to mid scale SMR and expander processes by

integrating an ORC to recover waste heat from a gas turbine

driver, producing designs that are energy efficient and cost

competitive.

1,2

These schemes are

the subject of this article.

Gas

pretreatment

Feed gas to an LNG liquefaction

plant requires removal of the

C

5+

components to less than

0.05 mol% and aromatics to ppm

levels. With lean US pipeline gas,

the use of a conventional scrub

column may not meet liquefaction

unit gas specifications. The use

of cryogenic separation may be

feasible, but at an incremental

cost. A viable solution can be the

use of the large pore molecular

sieves, which can simultaneously

adsorb water, aromatics and C

5+

components.

3

For lean gas, the

C

5+

content and aromatics may

be removed sufficiently to avoid waxing in the cold box. For

a low quantity of heavy hydrocarbons, the use of a molecular

sieve is an economical option over conventional processes.

Prior to the molecular sieve unit, the feed gas must be

treated in an acid gas removal unit (AGRU) to meet the CO

2

and H

2

S specifications. It must also be processed in a mercury

removal bed to meet specifications required to avoid mercury

corrosion in the downstream heat exchangers.

3,4

Organic Rankine Cycle

Rankine Cycles are used in steam cycle power plants. Instead

of steam, the cycle can also be operated using hydrocarbons

as the working fluid. The selection of the working fluid is

based on its condensation temperature, using ambient air

or cooling water as the cooling medium. The ORC power

cycle is illustrated in Figure 1. The condensed working fluid

is pumped to a high pressure (typically 600 psig), vaporised

and superheated using hot gas turbine exhaust. A recuperator

is used to recover the waste heat from the expanded gas,

increasing the cycle’s thermal efficiency. The high pressure

working fluid is then expanded in an expander to generate

power for the LNG plant. The working fluid is condensed and

pumped, and the cycle is repeated.

In cold climate operation, the ORC plant has an

advantage over a steam plant in that the organic fluid can

operate at a lower pressure, generating more power, without

the water freezing problems in a steam plant.

The thermal efficiency of a typical gas turbine is

approximately 36 – 40%. Therefore, ~60% of the heat

content is lost in the exhaust gas. The ORC plant, similar to a

steam plant, can achieve approximately 25% thermal

efficiency. The net result is a 35% higher power output per

Btu of fuel gas consumed in the gas turbine. The extra power

from the ORC can be used to drive the refrigeration

compressor or for power generation. This results in a

reduction in fuel consumption or an increase in LNG

production.

For the less efficient gas turbine drivers, it can be prudent

to recover the waste heat to reduce energy consumption and

CO

2

emissions.

Figure 1.

ORC – SMR LNG liquefaction.

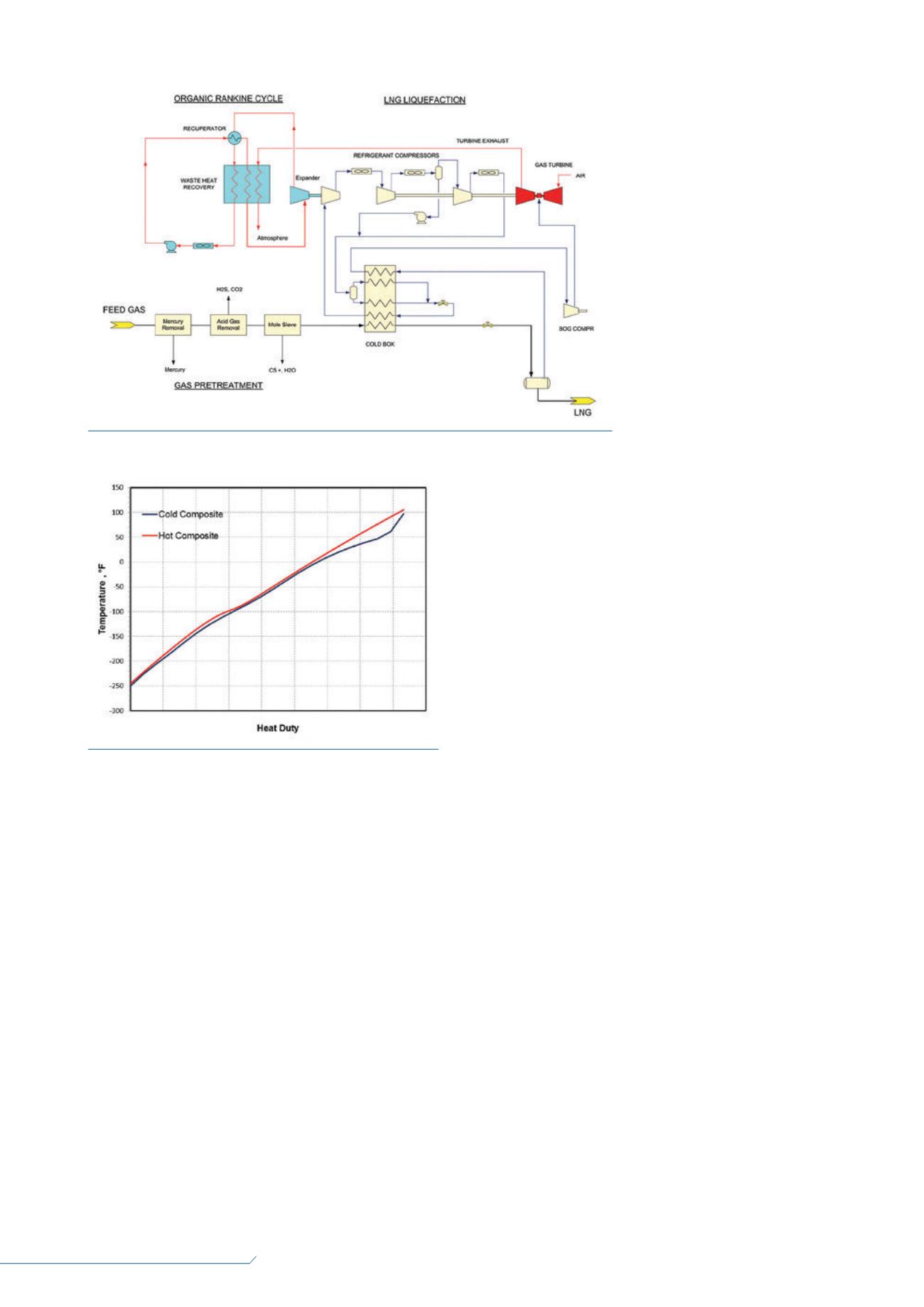

Figure 2.

Composite heat curve for SMR liquefaction process.