42

LNG

INDUSTRY

MARCH

2016

The solutions were designed using proven technology and

components of conventional onshore loading arms, supported

by 50 years of LNG transfer experience.

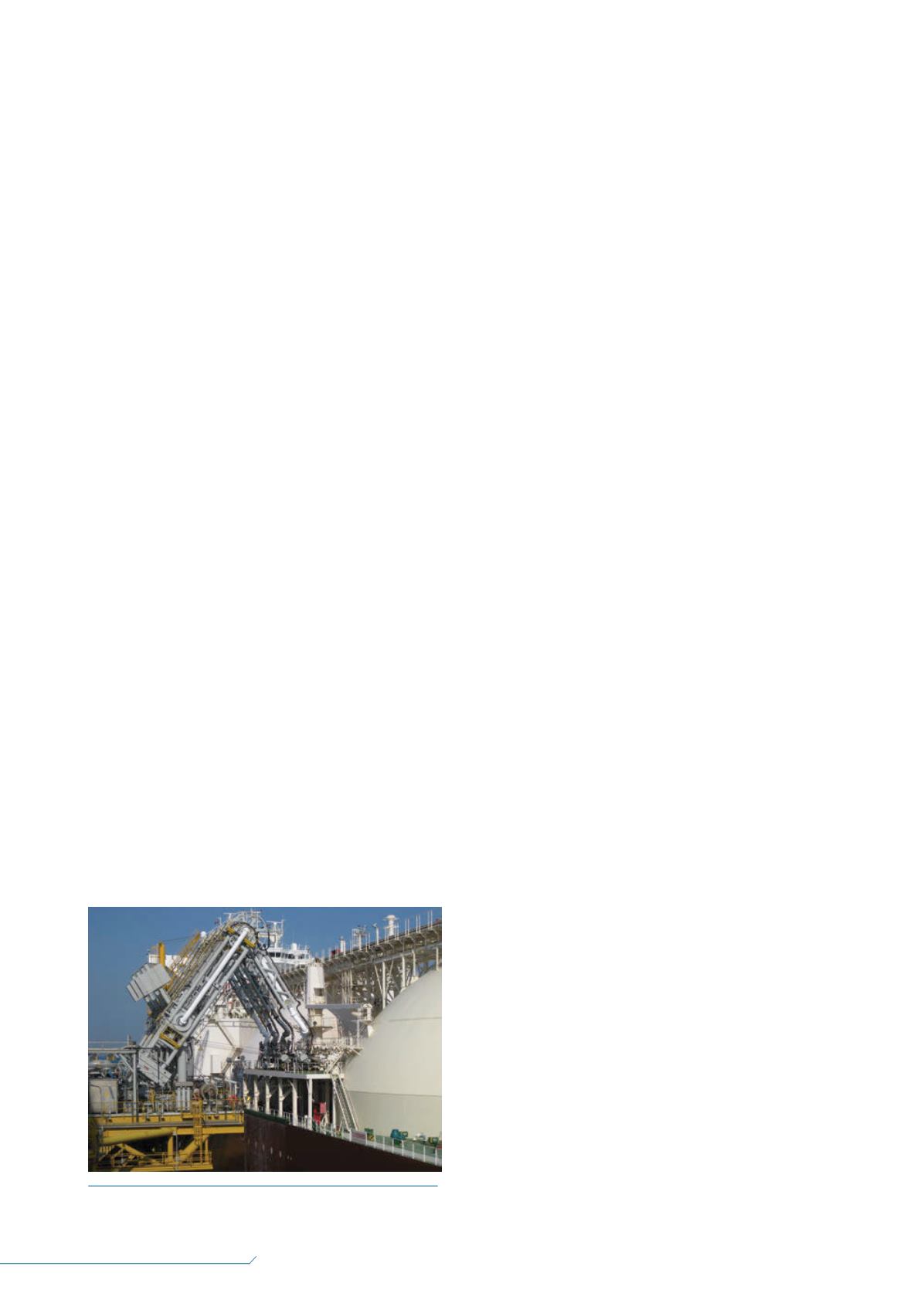

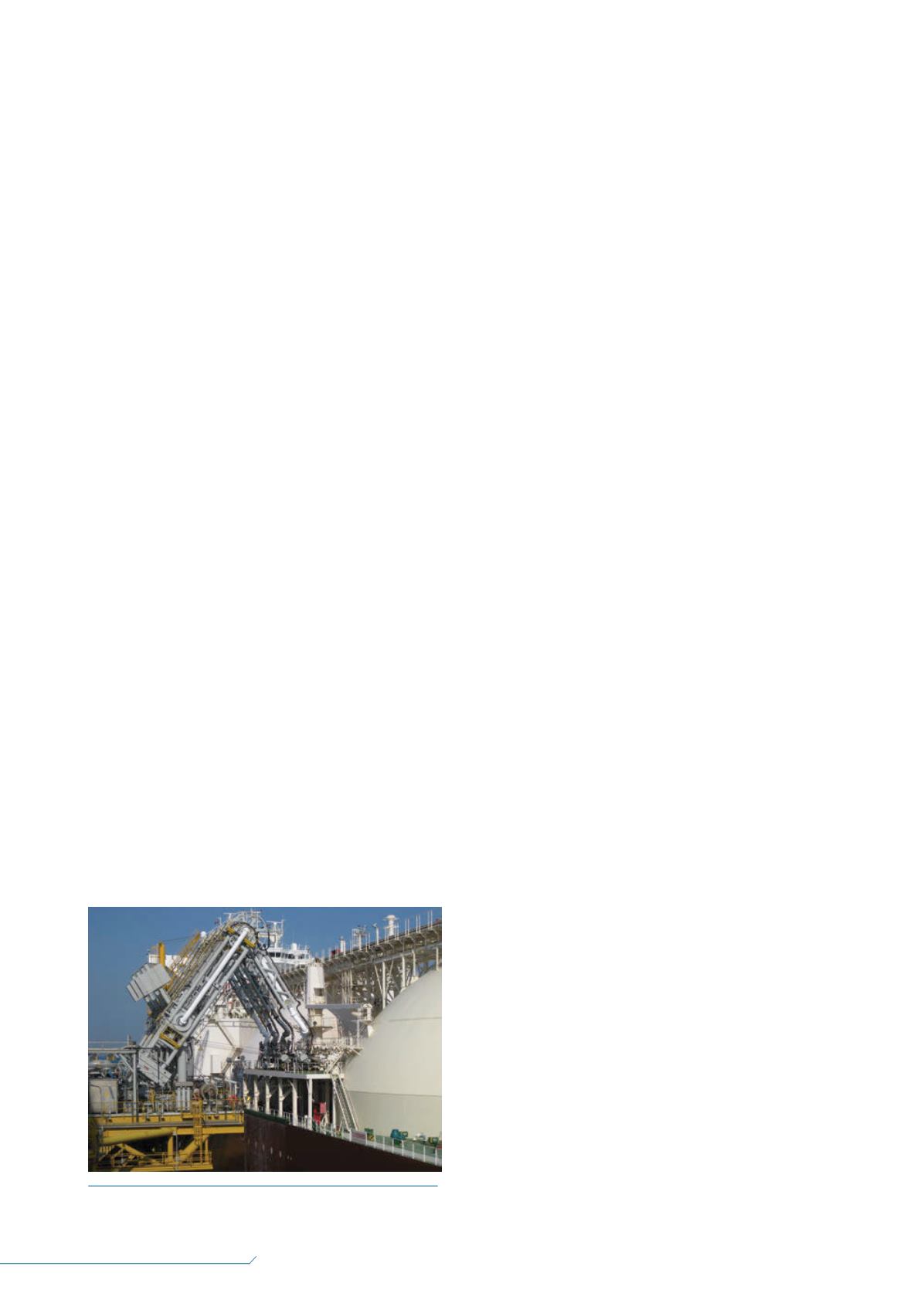

Side-by-side offloading

Technology challenges

When moving to nearshore and offshore locations, the loading

arms are installed between two floating structures, requiring

the replacement of traditional stress analysis with complex

non-linear methods to design and ensure the integrity of both

the loading arms and the LNG carrier manifolds during operation.

The fatigue caused by dynamic motions is a key consideration

in the design of the loading arms. It impacts the design of the

structural bearings and swivel joints, as well as the sizing of the

welding nets.

Assistance must be provided to allow full capability and

availability of the transfer system during the connection and

disconnection of the manifolds to the LNG carrier. The patented

targeting system developed by FMC Technologies consists of a

rope stretched at constant tension between the base riser of the

loading arms and the LNG carrier manifold. This guides the

loading arm, which is placed in passive mode during the

connection phase. A winch fitted at the end of the loading arm

drives the loading arm up to its final connection to the LNG

carrier manifold.

The control system has been rethought with care. In

conventional onshore LNG transfer, the loading arms use

proximity switches to detect the maximum extension and the

slewing limits. Meanwhile, a SIL 2 PLC manages the Emergency

Shutdown (ESD) sequences. A Position Monitoring System

(PMS) is used in parallel to monitor the position of the loading

arm coupling flanges.

The control system developed for offshore application

enforces a SIL 3 PLC and analogue sensors replace the proximity

switches. As a result, the operating envelope shape can be fully

customised in the Constant PMS (CPMS) and reflect exactly the

operating envelope defined during the engineering phase, which

comes from the outputs of the naval studies performed by the

engineering, procurement and construction (EPC) contractor. The

design of the loading arms is validated in stress and fatigue at

every location of the operating envelope. Thus, such CPMS

set-up ability is key to ensuring that the loading arms will never

remain connected to the LNG carrier manifold when outside of

this operating envelope. This system also enables the

implementation of safeguards to limit human errors.

Finally, the involvement of classification societies at an early

stage of the project has an impact on the design and execution

schedule.

FLNG: a new milestone

The transition from onshore to offshore operations has been

successful for the first FSRU/GBS projects and is close to

reaching a newmilestone with the upcoming deployment of

the first floating LNG (FLNG) projects. FMC Technologies has

supplied loading arms for Shell’s

Prelude

, Petronas’

FLNG

1

and

FLNG 2

and the Golar

Hilli

projects. The loading arms have

been mechanically completed and entered the start-up and

commissioning activities for the

Prelude

and Petronas

FLNG 1

projects whose first gas is planned for the next 12 to 18 months.

These floating facilities will operate in exposed

environmental conditions (typically up to 2.5 mHs), under which

it has been demonstrated that side-by-side offloading remains a

safe and viable operation. The excellent track record of marine

loading arms in the LNG industry – as well as the ability to

distribute LNG to conventional LNG carriers – naturally led to the

development of offshore loading arms.

Offshore systems and

maximised operability

Such specific operations require particular attention with regards

to the handling and maintenance of loading arms.

A variety of solutions are available to help conventional LNG

terminal owners install the loading systems, including the

following:

Training: almost every incident reported in the last 10 years

has highlighted the responsibility of personnel. Perfect

understanding and control of the equipment is key to

ensuring safe and continuous operations. Classrooms

and hands-on training sessions are proposed for loading

arms operators, as well as for electric, instrumentation and

mechanical maintenance supervisors.

Spare parts and maintenance: the maintenance programme

of the loading arms shall be defined at an early stage of the

project execution phase. On some projects, a fourth loading

arm has been considered for redundancy purposes. The

maintenance activities have to be coordinated by skilled

supervisors.

Such aftermarket programmes are managed through regular

specialist site interventions on import/export terminals, FSRUs

and GBSs, to maintain equipment performance and operator

competence.

When producing LNG offshore (FLNG), the consequences of

loading arm downtime can become critical in a short period of

time, because of continuous operations and limited LNG storage

capacity. The increased duration required to reach the floating

unit must also be taken into account. Full time assistance

onboard the floating unit is a new approach to the operation and

maintenance management that is seen in upcoming FLNG

projects. FLNG operator companies are particularly interested in

maintaining the offloading function along the FLNG operation

life, hence encouraging the loading arm supplier to remain fully

involved in the maintenance of the equipment after delivery.

Figure 2.

Offshore loading arms of Adriatic LNG.