44

LNG

INDUSTRY

APRIL

2016

and highly efficient package. Through this progression, and

the associated recognition from the American Petroleum

Institute (API), IGC compressors now see significant market

penetration and have become a dependable solution that

many industries look to for their compression needs.

1

Case study

On a recent project intended for installation in Nigeria,

compressor manufacturers were approached in 2H14

regarding their ability to supply multiple compressors for

LNG trains on an expedited basis. A 0.50 million tpy LNG

plant was at stake, which would need, among several other

major purchased components, a mixed refrigerant (MR)

gas compressor. The specifications of the project would

require four compressors to manage the total flow of gas,

and they would all need to be delivered in a critical six to

eight month window. Based on reliable and proven designs

with similar applications, it was expected that more than

one supplier would be able to develop the right solution

within the time constraints, as well as begin contract-specific

engineering work less than a month after the original inquiry.

As with many fast-tracked projects, an original equipment

manufacturer’s (OEM) ability to quickly assemble a team,

formulate a solution, and provide the necessary information

are vital to meeting the customer’s goals.

Efficient and reliable

The client was determined to meet the project schedule,

but also knew that it needed to meet the given efficiency

and reliability requirements. IGC compressors were selected

due to their proven ability to meet all of these requirements.

Equipment durability parameters, such as reliability,

availability, and mean time between failures (MTBF), were

compared and evaluated during the equipment selection.

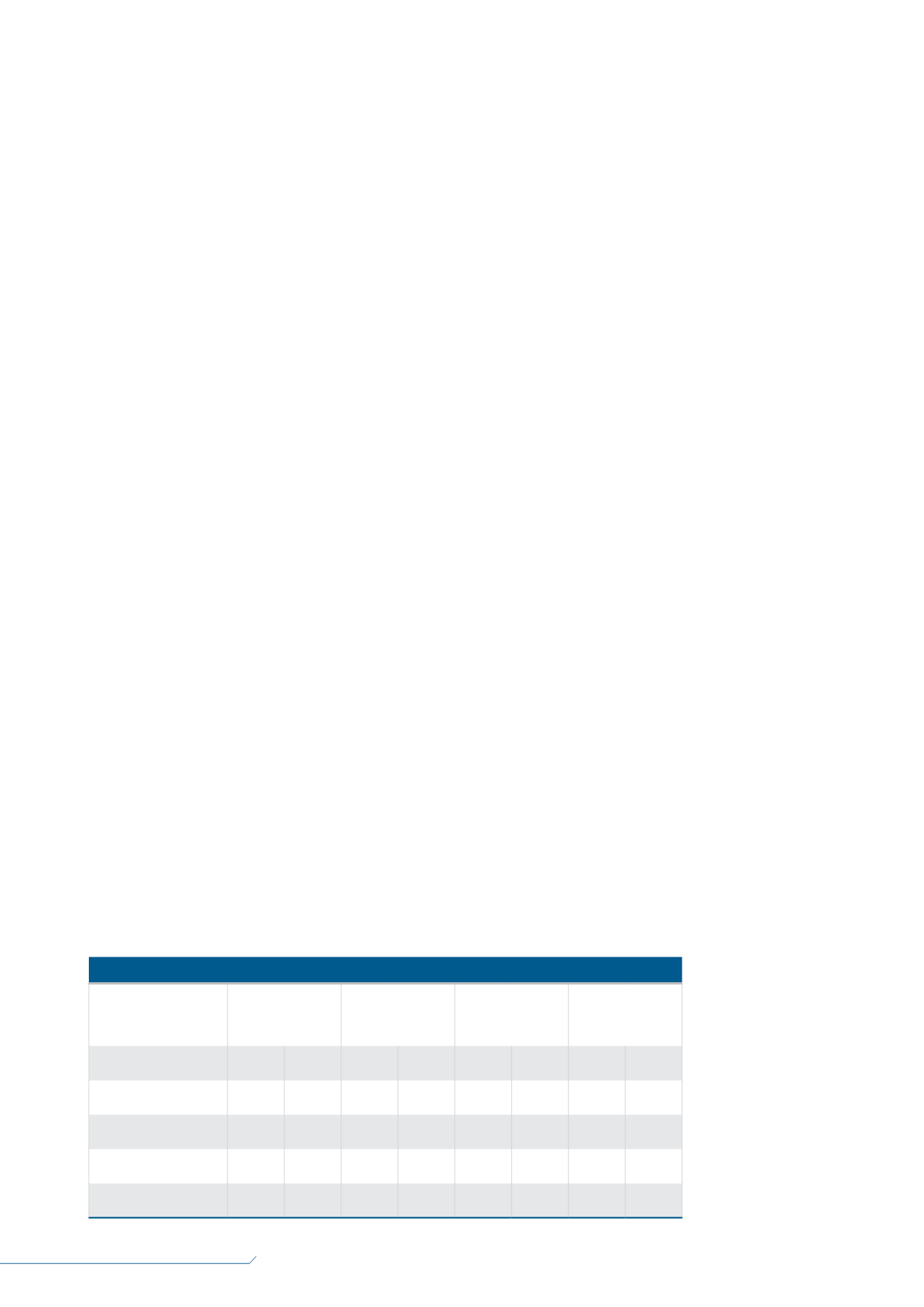

Table 1 illustrates the relative differences in such categories.

2

Finding an LNG compression solution

Fortunately, the compressors required by this application

aligned well with a recently completed project for another

end-user. As is typical in the process gas compression

business, no two applications are ever the same, and thus

the main compressor design would need to be tweaked.

Details ranging from high level API requirements, to finer

specifics, such as superheat, rise to surge, and turndown

range, were worked through at great pace and with a high

level of detail in an effort to create a clear path forward.

The essential front-end engineering for the compressor

design needed to be worked on in an expedited basis due

to the schedule constraints. In the weeks leading up to the

contract award, direct dialogue between the aerodynamic

design engineers and the client’s process engineers was

often required to quickly work through specific questions

and to iterate the best design solution. Requested

changes in the preliminary process conditions needed to

be analysed and the individual engineers responsible for

the impeller (aero) design, rotordynamic stability, and

mechanical integrity all verified the design selection,

which was then reviewed with and approved by the client.

Project management resources responsible for the

execution of the compressors were also mobilised early in

the process to assist in the necessary meetings, as well as

with customer documentation requirements. The

compressor contract was ultimately signed by the

involved parties by the end of September 2014, with a

forecasted ship date for all four compressors in the late

spring of 2015.

Scope of design

IGC compressors are well suited and adaptable to

the varying process conditions for gas compression

applications. The compressor utilises a large helical-cut

bullgear driven at low speeds to drive multiple pinion

gears with overhung impellers. The integral gear design

allows for the rotational velocity of each pinion gear

to be designed based on the optimal aerodynamic

characteristics of the impeller. The intrinsic design

arrangement of IGC compressors naturally separates

the lubricating oil in the gear casing from the process,

ensuring oil-free process gas without the need for

additional separation systems. Some OEMs employ

enhanced measures, such as an atmospheric air gap

between the gear casing and compression volutes and/or

maintaining the gearbox at vacuum pressure to keep

lubricating oil from seeping out of the casing, to further

ensure the delivery of oil-free gas.

3

Based on the requirements of the LNG train, the MR

IGC compressor was rated for a maximum power of

9300 hp, sized accordingly for a variety of design points,

such as maximum flow, maximum ambient temperature,

minimum ambient temperature, and gas recycling. In this

case, and as with most designs, it was imperative to fully

understand and analyse each of the required operating

conditions;

specifically, changes

to the inlet suction

temperature, coolant

temperature,

molecular weight,

and required gas

flow. All of these

conditions were

known to change

from season to

season, and on a

more granular level

from day to day.

Along with the

aforementioned basic

Table 1.

Availability and reliability parameters for different compressor types

Availability (%)

Reliability (%)

Proactive

maintenance

downtime

(hr/yr per five years)

MTBF (yr)

Compressor type

Best

Average Best

Average Best

Average Best

Average

Reciprocating (lubricated)

99.5

97.3

99.8

97.8

120

240

1.5

0.5

Screw (oil-flooded)

99.2

97.7

99.8

98.8

250

300

3

1.5

Screw (oil-free)

99.6

99

99.9

99.7

150

300

10

5

Centrifugal (clean service)

99.9

99.7

100

99.8

12

30

15

8