For typical BOG sources and indicative flows for a floating

storage and regasification unit (FSRU), refer to Table 1.

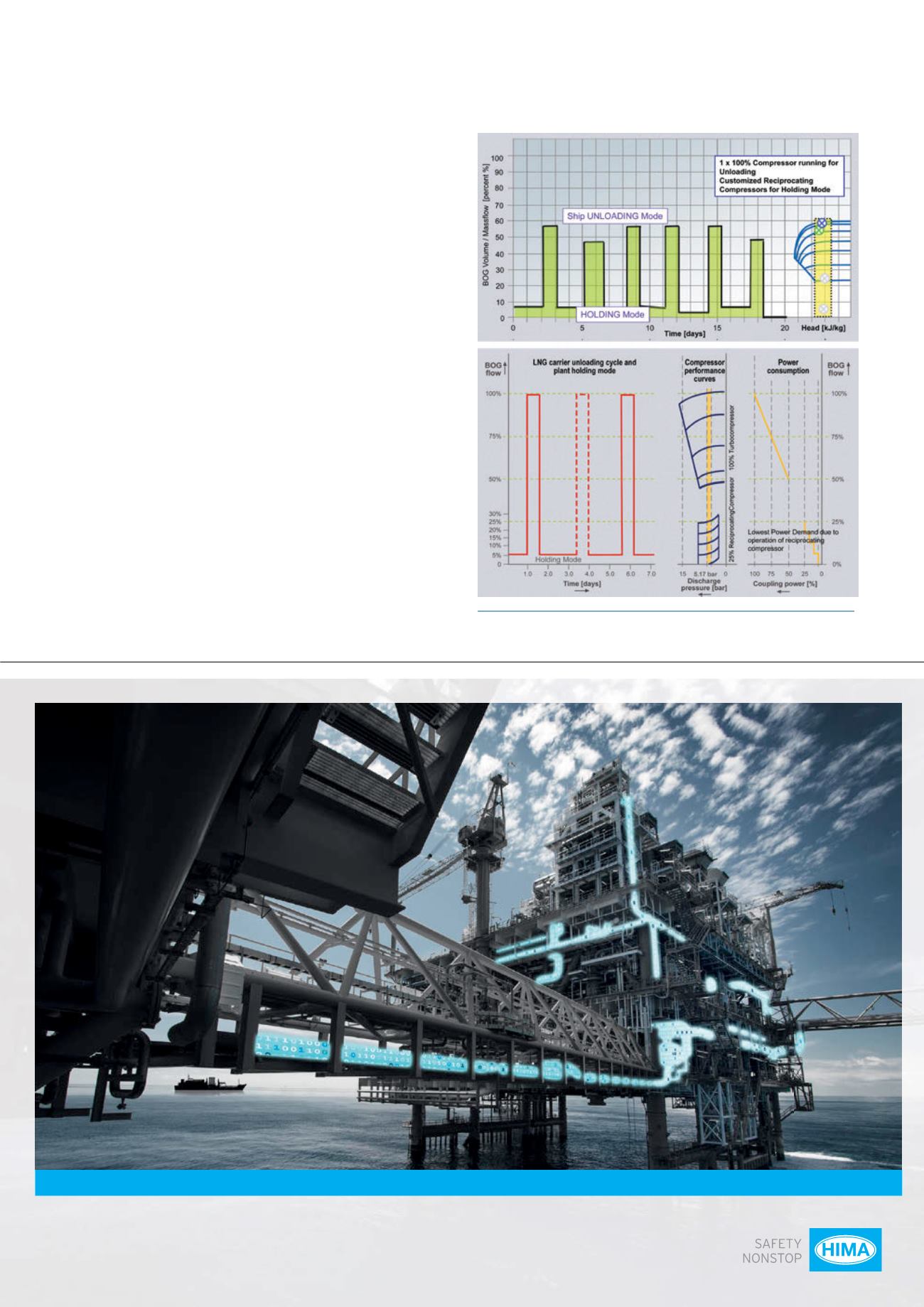

The relatively high maximumBOG flow and the difference in

BOG volume fluctuations between holding and ship unloading

require a combined compressor concept. In Figure 4, the spread

ranges from 32 tph down to 2 tph, which can only be handled by

combining both the strength of the single-shaft turbocompressor

and reciprocating machines.

While the loading requirements are handled by one 100%

turbocompressor package, the small holding operating points are

operated by either existing terminal extensions, or new

reciprocating compressor packages.

With the configuration outlined in Figure 4, optimised

compressor BOG handling concepts become increasingly attractive.

Rather than covering the whole BOG flow range by small LNG

re-liquefaction units (single-cycle N

2

LNG cooling), or multiple large

reciprocating compressors (re-condensing concept), it is more

energy efficient to cover the maximumBOG duty through a

single-casing, single-shaft centrifugal compressor combined with

reciprocating machines.

In summary, of the outlined concept descriptions and based on

the factors of maximumBOG flow and minimumBOG flow, the

following compressor concepts (visually portrayed in Figure 5) for

BOG handling can be used:

Concept A (conventional arrangement for LNG receiving

terminals):

2 x 50% (plus one spare) or 3 x 33% reciprocating

compressor.

Figure 4.

Simplified BOG generation and operation profile (LNG

import terminal), combining turbo and reciprocating compressors.

ESD

F&G

HIPPS

Subsea

Pipeline

TMC BMS

Comprehensive

Safety Solutions

increase Profitability

Visit us at OTC in Houston: Hall B, Booth 4527-17