48

LNG

INDUSTRY

APRIL

2016

Along the whole LNG chain – during production,

transportation and regasification – BOG is constantly evaporating

from the LNG, which is bunkered in storage tanks at cryogenic

temperatures and atmospheric pressure. According to its nature,

the BOG flow profile differs along the different steps of the value

chain, thus the requirements on BOG compression also differ.

BOG generation during LNG carrier transportation, while

constant, is rather small. For LNG export plants and LNG import

terminals, the maximumBOG volume flow is much greater and

faces large fluctuations. This is due to the impact of increased

heat leakage during ship loading (export plant) and ship

unloading (import terminal).

In LNG export plants, the BOG generation rate is the highest

along the LNG chain and the BOG flow undergoes large volume

fluctuations defined in two major plant operating modes.

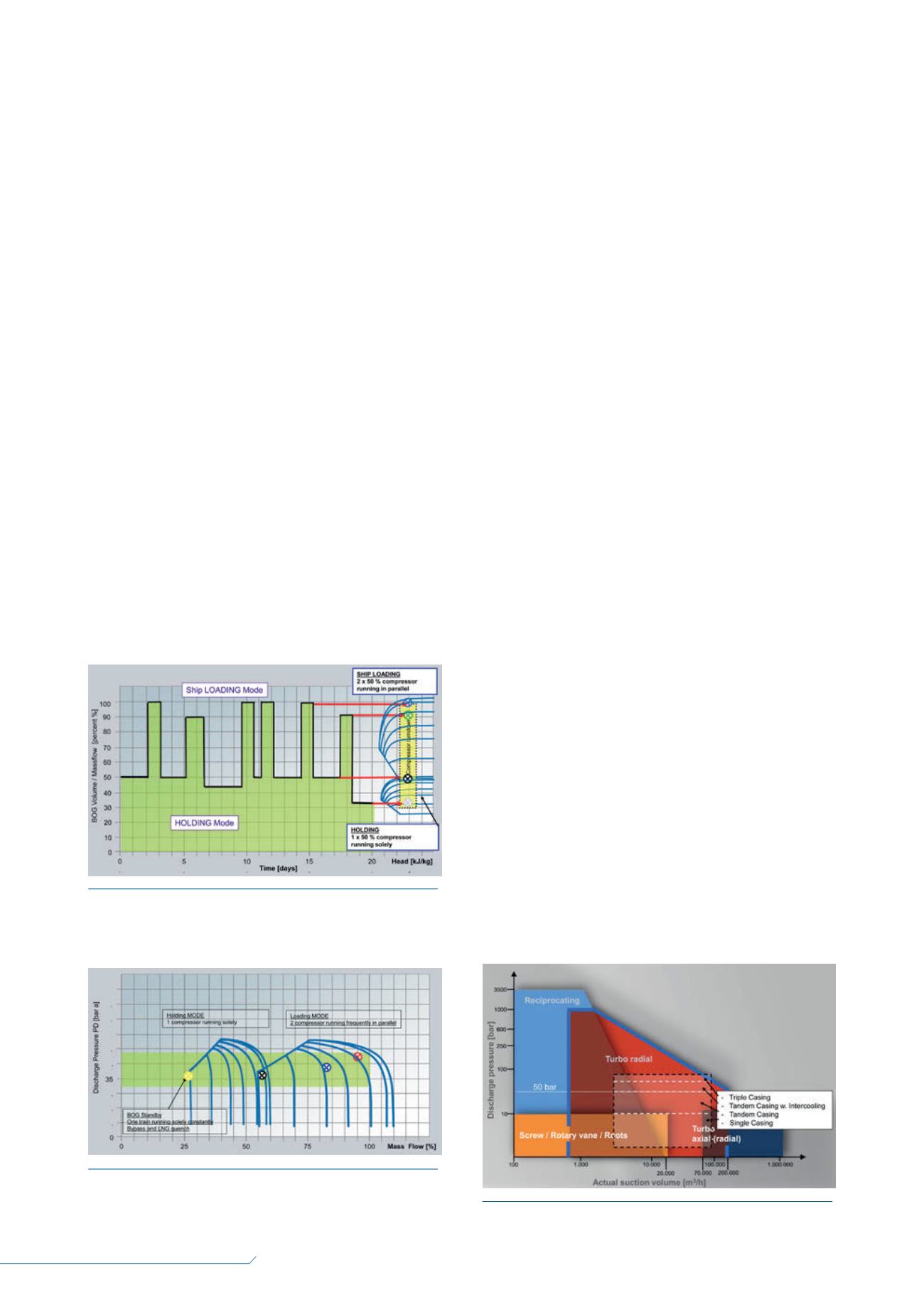

Figure 1 shows the project-specific LNG BOG/end flash gas

(EFG) generation profile over time with one almost constant BOG

and EFG flow called ‘holding’ and a characteristic peak in BOG

volume flow during ship loading.

The different BOG volume flows are caused by different heat

leakage sources. In the holding (BOG/EFG) example, onshore

LNG tank heat leakage and the flash effect from LNG production

(main cryogenic heat exchanger pressure flashed down to

storage pressure) are the key sources of heat leakage.

In the ship loading example, heat leakage comes from the six

submerged LNG pumps (approximately 1 – 2 MWeach), the jetty

piping and the LNG ship cargo.

On the right side of Figure 1, the 2 x 50%overlapping BOG

compressor performance maps have been flipped with different

inlet guide vane (IGV) settings. The holding operating point (blue

dot) is basically the main operating point and for that reason

should run at good efficiency and without any bypass flow and

LNG quench.

In Figure 2, the ship loading operating point (red dot)

represents the peak volume flow, which occurs frequently and is

covered by starting another BOG compressor train. The graphic

also shows a BOG flowrate of 2 x 50 tph, which equals a 100%

mass flow – a usual value for today’s typical LNG plant.

By serving the flow requirement with either one or two trains,

all operating points are covered with a single-casing BOG

compressor.

Some loading operating points, especially at the beginning of

the new loading cycle, temporarily increase the BOG temperature

above the design point ranging from approximately -145°C

(-229°F) down to -160°C (-256°F). Thus, volume flow increases

and outlet pressure decreases.

Allowing minor LNG quench of approximately 3 – 5% for the

initial loading operating point would provide a more compact

compressor that can be maintained while featuring a 2 x 50%

solution instead of a 3 x 33% arrangement. By this measure,

recycle flow can be minimised, or even prevented, while outlet

pressure can be maintained.

All specified operating duties can be covered with two

identical tandem-casing BOG single-shaft centrifugal compressor

trains. This solution for process optimisation would ensure

minimum equipment count and the lowest installation volume,

while still maintaining maximum operating reliability, availability

and safety.

In LNG plants, the BOG, together with the EFG coming from

the flash drum, is often used as fuel for gas turbines. Thus, the

fuel gas pressure required by the turbine significantly affects the

required BOG compressor concept. Despite inherent flow

fluctuations, the BOG package needs to deliver the flow at a

specified pressure to satisfy the fuel gas pressure requirement for

the gas turbines in the facility.

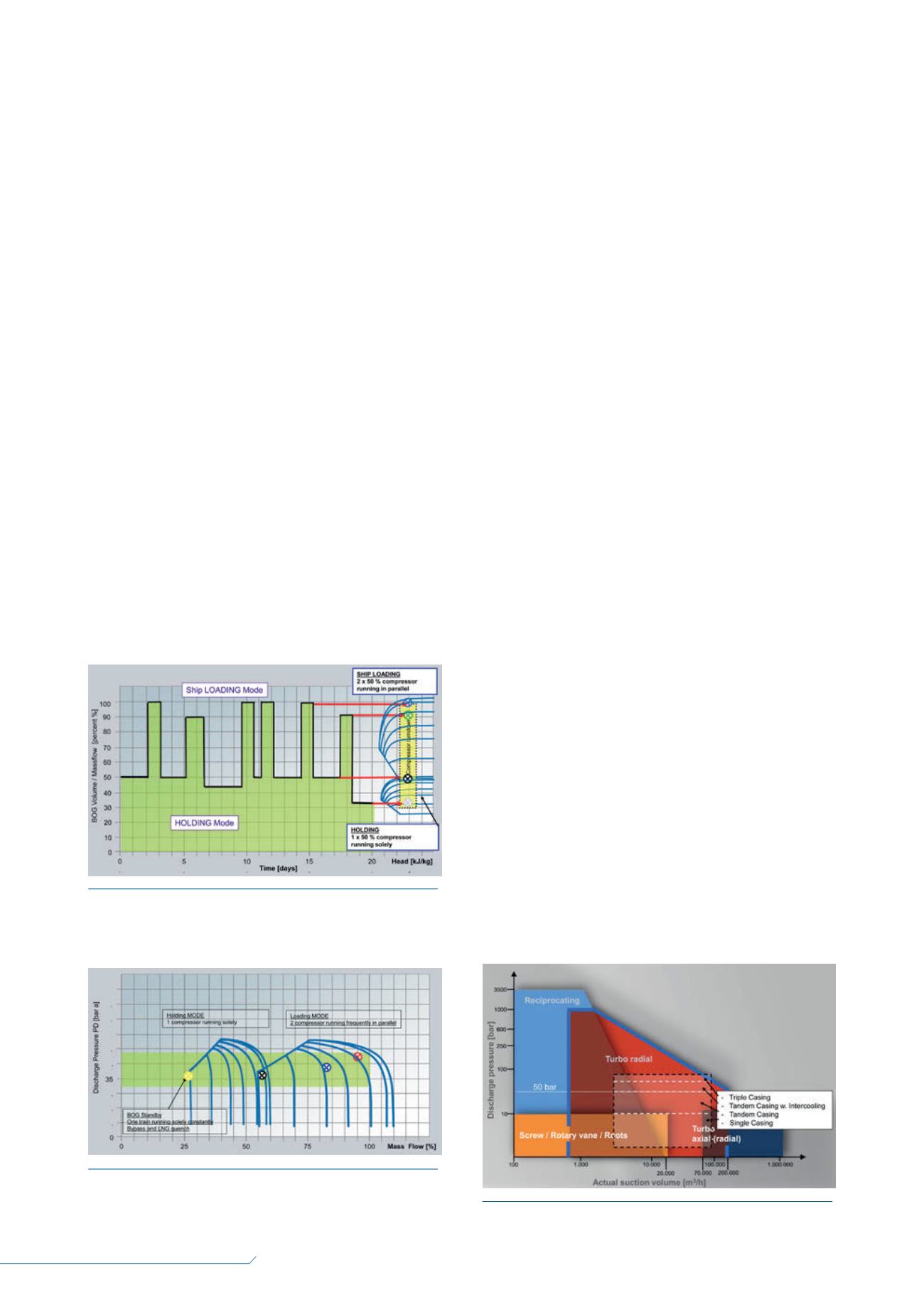

Depending on the different fuel gas pressure requirements,

single, tandem, or even triple-casing BOG compressors may be

required (Figure 3).

An unconventional arrangement

for LNG import terminals

In LNG import terminals (onshore or offshore), there are two

major operating modes – holding mode and unloading mode –

which determine the BOG duties.

Figure 2.

Using the 2 x 50% BOG compressor model from

Figure 1, the predicted compressor performance can be mapped

out, inlcuding the peak volume flow of the BOG compressor.

Figure 3.

The application range of different compressor types.

Figure 1.

A boil-off gas (BOG) generation profile (2 x 50%

BOG compressor concept) at an LNG export plant showing the

flow fluctuation between the holding and loading modes.