40

LNG

INDUSTRY

APRIL

2016

captive rectifier/harmonic filter transformer powering each of the

three large compressor strings in each unit. Each compressor

string is powered by a synchronous motor drive through a variable

frequency drive (VFD) that is connected to the captive

rectifier/harmonic filter transformer. These drivemotors are

controlled and protected by the VFD. Additionally, within each

LNG train, two 138 kV feeders serve the primaries of two

138 – 13.8 kV power transformers that will supply 4.16 kV, 480 V,

and 120/208 V stepdown power transformers. In general, these

transformers are arranged in double-ended, main-tie-main

arrangements to serve all of the remaining loads.

Diesel generators and uninterrupted power supplies (UPS)

featuring battery backup are provided within each LNG train for

essential loads.

Plot plan of an E-LNG plant

When compared to a conventional, same capacity, gas turbine

driven compressor train, the all-electric train requires a larger plot

space, primarily due to the ancillary equipment that the electrical

motors require.

Figure 1 is a snapshot of the 3Dmodel showing the three

compressor strings: (from left to right) the propane compressor

(shown without noise enclosure; note that all compressors and

motors are located inside off-skid enclosures that are installed on

top of the concrete compressor table tops), high pressure/

mediumpressureMR compressor (shown without shed) and the

low pressureMR compressor. Table 2 shows major electrical

components and its approximate plot area.

It is recommended to procure capital spares, such as a

completemotor (stator and rotor) as well as a VFD

rectifier/transformer and one set of VFD harmonic filter legs,

which are long lead items. Due to the large size and weight of

these components, a detailedmaintenance plan needs to be

developed to ensure that there is sufficient space to bring in large

cranes, as well as to ensure that the roads and warehouse are

designed to receive this heavy equipment. Table 3 shows the

approximate dimensions and weight of major electrical

components.

Availability/flexibility

As shown in Table 1, electric motor drives and aeroderivative gas

turbines providemore available days compared to industrial gas

turbines.

Aeroderivative gas turbines need inspection and servicing

every six months, major maintenance every three years and an

engine swap every six years. Engine swaps require the plant

owner to purchase a set of extra gas turbine enginemodules

equivalent to one LNG train. Frequent inspections cause frequent

shutdown of the gas turbine and coupled compressors. Engine

swaps require removing the engine from the plant for an overhaul

and, typically, offsite or onsite storage, which are all major

undertakings.

Electric motors are designed to run for three years without

interruption. It is possible to build redundancy within the

electronics in-drive system to extendmean time between failures

of the drive systemup to two to three years or even longer.

Freeport LNG’s concept of threemotors per train also

separates control of two refrigeration loop compressors fromeach

other, which simplifies overall liquefaction operation control. The

propane refrigeration compressor rotating speed can be adjusted

without directly affecting theMR compressors, since they are not

coupled to the same driver. A typical LNG plant with industrial gas

turbines has two compressor casings coupled to one gas turbine

and any rotating speed adjustment of one compressor affects all

of the connected compressors.

Electric motor drive selection for Freeport LNGwill increase

uptime and provide an opportunity for simplified operation

control.

Table 3.

Dimensions and weight of the main electrical

components

Item

Dimensions: length

x width x height (m)

Weight (t)

75 MW electrical

motor

10 x 6 x 7.3

245

75 MW VFD

16.4 x 10.4 x 2.7

37

138 kVA transformer 8.9 x 6 x 7.4

95 (transport weight

– without oil)

Table 2.

Plot area requirements for major electrical systems

Item (see Figure 1) Description

Plot area (m

2

)

1

138 kV transformer

105

2

E-house building

(compressor VFD, low

voltage motor control

centre (MCC), unit control

panel (UCP) system,

fire and gas (F&G) for

compressor and motor

enclosure)

550

3

Compressor and motor

550

4

VFD cooling package

450

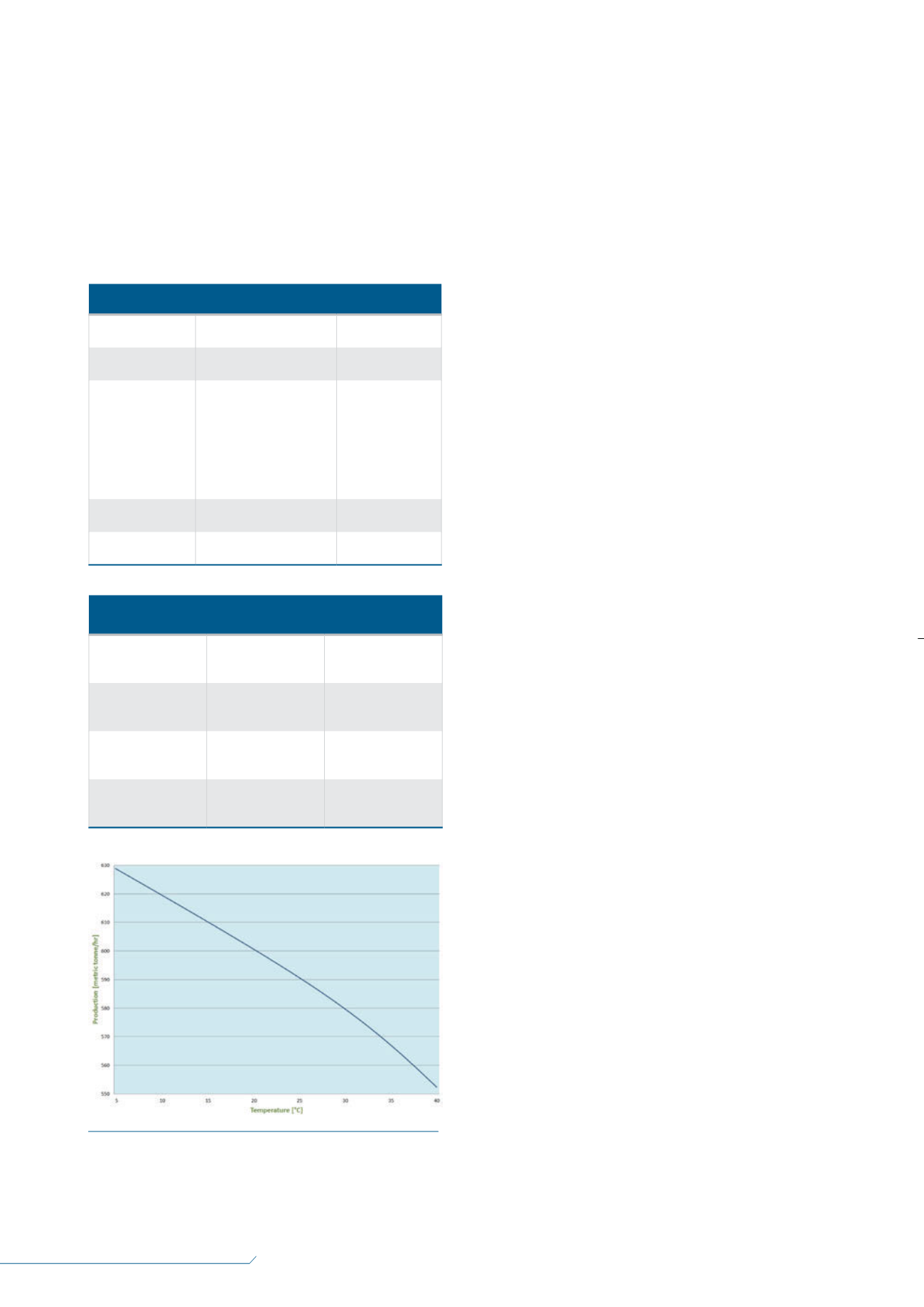

Figure 2.

Estimated production profile for all-electric

refrigeration cycles (air cooled liquefaction plant).