The process

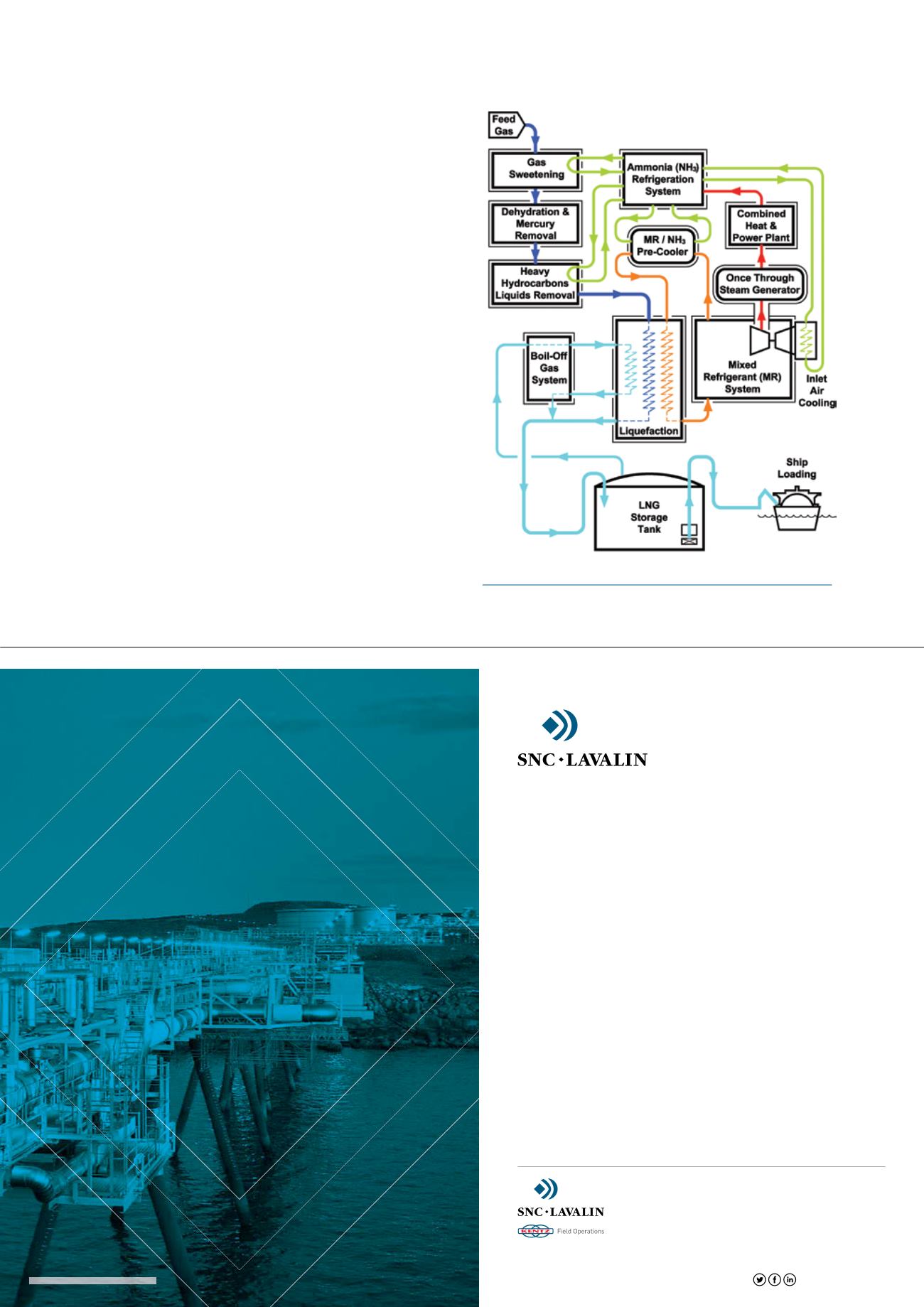

Figure 4 shows a schematic representation of the liquefaction

process technology.

Pretreatment

Feed gas routes from the gas gate station to each LNG train and

initially passes through an inlet filter coalescer to separate any

liquids/solids to prevent foaming in the acid gas removal unit

(AGRU). Removal of acid gases (CO

2

and H

2

S) using a proprietary

amine solution occurs in an absorber column. Removal of CO

2

to approximately 50 ppm avoids freezing in the downstream

liquefaction unit. An ammonia refrigeration systemprecools the

water-saturated sweet gas exiting the absorber column, which

passes through a knockout separator to remove bulk water from the

gas. The condensed water and trace amounts of amine are recycled

to the amine system as make-up water.

Depending upon the design of the dehydration unit, the gas

recycled back to the process will beminimised, or even eliminated.

The dry gas stream also accommodates any shortfall in fuel gas.

Amercury removal unit, provided after themolecular sieve dust

filters (typical position), removes any tracemercury in the gas prior to

entering the liquefaction unit. A treated gas filter downstreamof the

mercury removal unit is also in place to capture any loose dust

particles from themercury removal system.

Heavy hydrocarbon removal plant

The final pretreatment unit involves removal of heavy hydrocarbons,

such as pentanes and benzene. Benzenemust be removed to avoid

freezing in the liquefaction plant. The heavy hydrocarbon removal

Figure 4.

Schematic of OSMR liquefaction process

technology.

Proven LNG

Capabilities

Our 20,000-strong Oil & Gas professionals deliver end-to-end

services to our clients in the global LNG sector.

We offer capabilities in:

›

Liquefaction plant build

›

Completions and commissioning

›

Non-process infrastructure

›

Marine infrastructure

›

Operations and maintenance

›

Telecommunications

›

Re-gasification and receiving terminals

›

Off-sites and utilities

›

Gas processing and handling

›

Pipelines and compressor stations

snclavalin.com

Pluto LNG, image courtesy of Woodside

SNC-Lavalin Kentz Field Operations is world

renowned for providing multi-disciplinary

construction and technical field services.