26

LNG

INDUSTRY

APRIL

2016

Opportunity

Linde has developed StarLNGL™ – a technology that

integrates the production of LNG into a new or existing NGL

plant.

1

This approach is a cost-effective method of producing

LNG because it eliminates redundant infrastructure and it

improves the overall efficiency of the NGL operation. NGL

production can even increase.

Market context

The current price of oil and gas commodities can easily

distract the view toward short-term strategies. Instead, US

midstream operators should think long-term and consider

the vast potential on the horizon. The US is poised to remain

one of the largest NGL suppliers for as much as two to

three decades, according to the US Energy Information

Administration (EIA).

2

With fluctuating market conditions, operators need

flexible solutions to follow these complex arbitrage schemes,

so that they can optimise the monetisation of natural gas

feedstock in the different product sales channels. For

example, ethane can be traded as part of the NGL product

stream to downstream facilities (e.g. ethane crackers, etc.) as

feedstock, or can be sold at its heating value as part of the

residue gas of an NGL plant. Similarly, oil and gas companies

could bring methane to the market as a pipeline gas, or LNG,

to be exported or to service domestic satellite stations to fuel

LNG-driven ships, trucks, or locomotives.

However, in the short-term, LNG is playing a relatively

small role in the domestic market due to the slow growth of

infrastructure, current low oil price, and slow conversion to

LNG in the transportation sector. These factors favour a

softer, reduced risk entry into the LNG sector according to

delayed LNG market development. This approach is opposite

to the concept of the traditional baseload LNG plant.

While investors evaluate their options, many companies

are seeking lower cost bolt-on acquisitions in the NGL

segment, or are exploring

non-traditional

partnerships. Either way,

there is a clear opportunity

for companies to create

enhancements that offer

value for customers, while

opening new revenue

sources. However, it

requires significant capital

to invest in a new,

standalone LNG

processing plant. This

does not fit well with

current market conditions.

Instead, midstream

companies are looking for

projects with low CAPEX

and high rates of return to

reduce their investment

risks.

A solution

One solution is to

coproduce LNG in an

NGL plant. StarLNGL

takes advantage of existing cryogenic investments by taking

its feed gas from the cryogenic column overhead of the

NGL plant. This way, LNG can be made more efficiently. By

contrast, a standalone LNG plant would take gas at ambient

temperatures and require additional duty from the refrigerant

to cool it to cryogenic levels.

Further, by routing some cold column overhead gas to the

StarLNGL plant, the host NGL plant enjoys a debottlenecking

advantage so that it improves plant throughput and

operational efficiency. Combined, this integrated solution will

produce LNG while also increasing NGL recovery. Additional

NGL revenue results from increased NGL production due to a

higher reflux stream routed into the NGL plant’s cryogenic

column, and from the concurrent debottlenecking of the

residue gas system. In addition, a higher reflux stream can

increase the NGL plant’s recovery rates. Linde estimates a

total efficiency increase of between 5% and 10%. With those

improvements, installing the LNG bolt-on will create savings

to return the investment in a short time.

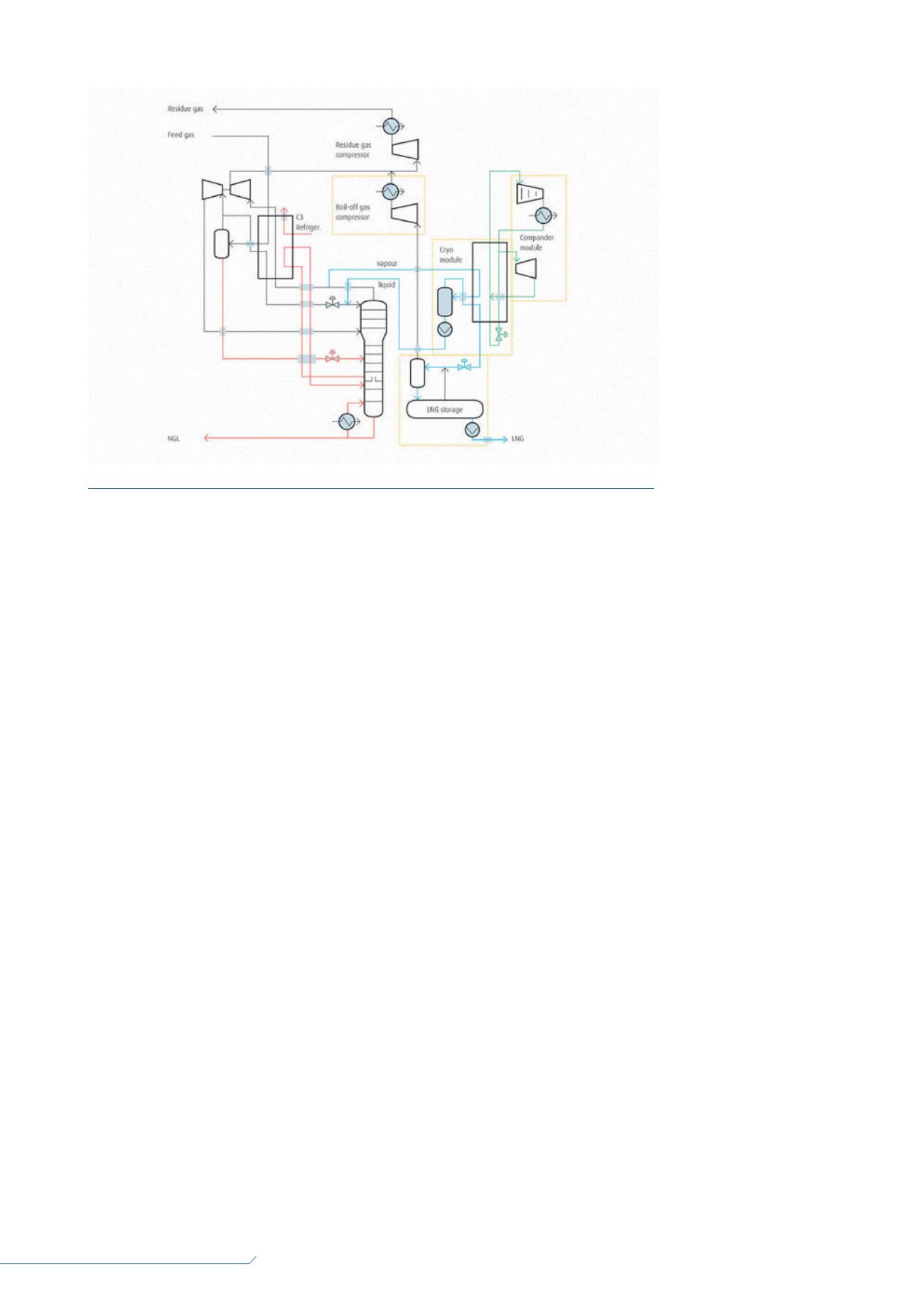

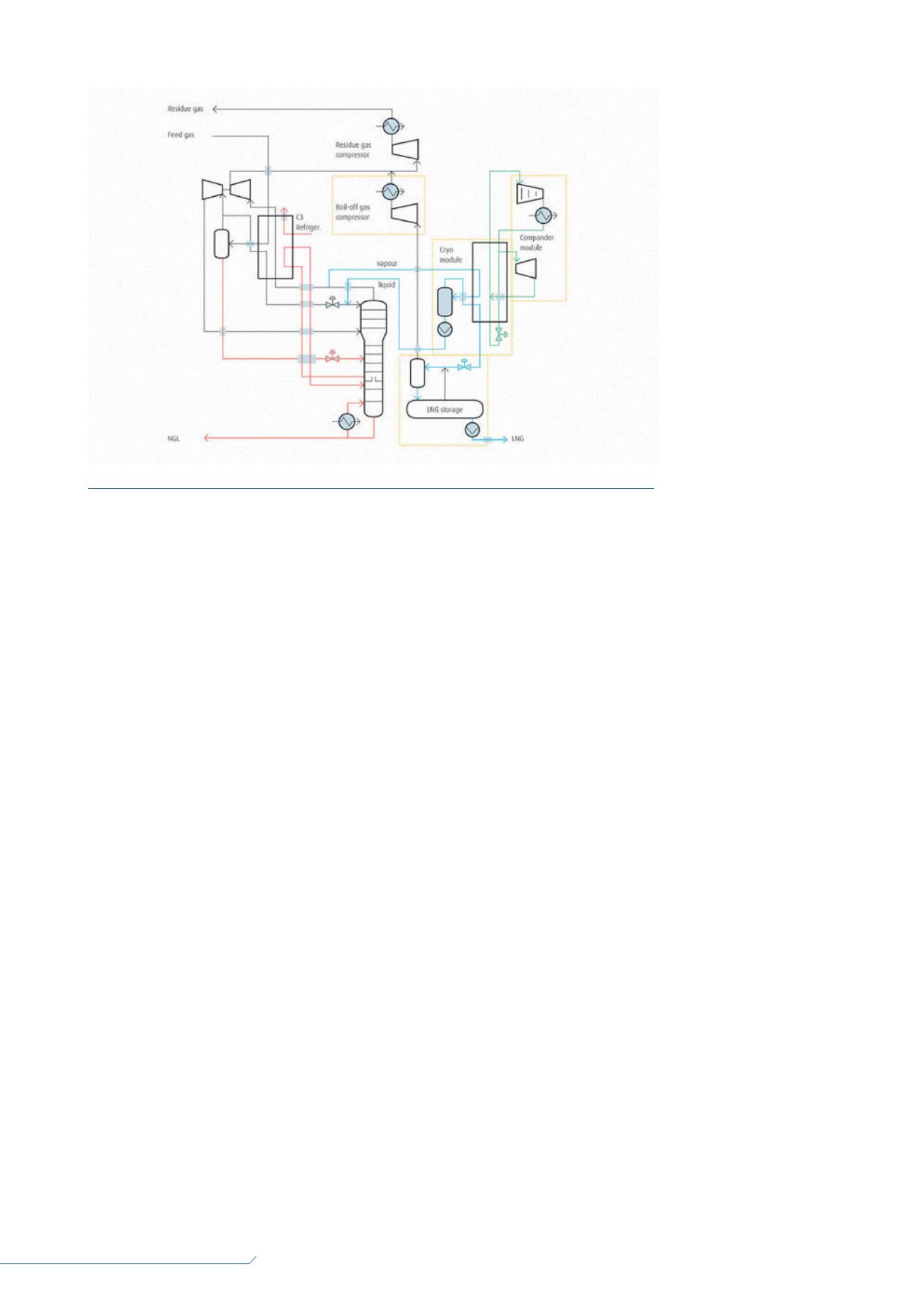

The left half of Figure 1 shows the equipment of a

conventional NGL plant arrangement with a feed gas

turboexpander, a light ends fractionating column (LEFC), a

heat exchange system, and, in many cases, external propane

refrigeration. Residue gas (LEFC overhead) is re-heated and

re-compressed to pipeline pressure with the shaft power of

the expander, and with external power via a residue gas

compressor. In the right half of Figure 1, the StarLNGL

arrangement added to a NGL recovery plant is shown. The

cold vapour leaving the overhead of the LEFC of the NGL

recovery process is routed to the StarLNGL liquefaction heat

exchanger, a brazed aluminium plate-fin heat exchanger. The

vapour stream is further cooled against the refrigerant of the

refrigeration cycle in the heat exchanger’s precooling section.

This results in partially condensed natural gas entering the

reflux separator to allow for removal of the liquids (C

2+

) from

the vapour phase (mainly CH

4

). The recovered liquids are

Figure 1.

Process flow of a standardised StarLNGL

TM

plant (yellow dotted lines) integrated into an NGL

extraction facility (NGL plant).