22

LNG

INDUSTRY

APRIL

2016

Early planning and development

In its early stages, implementation planning is connecting the dots

between the FERC DEIS/EA (which detail the draft conditions

that the project may receive in its permit), the requirements of the

EPC contract, and the EPC contractor’s construction schedule.

Ideally, the developers will put together an implementation

plan (IP) team consisting of representatives from the developer,

the EPC contractor, legal counsel, those knowledgeable about

environmental aspects and the engineering design of the project,

and those knowledgeable of the permitting effort and future

permitting requirements for the project. The goals for the IP team

should be as follows:

Identify all permits and approvals and the associated

processes that must be followed to obtain such permits and

approvals.

Ensure the project properly plans in advance for all federal,

state, and local requirements and inspections.

Ensure the project complies with all federal, state, and local

permits.

Ensure the project does not sustain any delays in approvals for

construction, which will result in impacts to the construction

schedule and associated construction cost.

Ensure the project fully understands all engineering design

requirements that were incorporated into the permitted

design or imposed as conditions to the design.

Ensure the project has a fully developed implementation plan

for the execution phase of the project.

Implementation planning is usually first started in a workshop

with the IP team following a generic sequence:

Firstly, the IP teambreaks down all of the FERC DEIS

conditions to understand what the requirements of each

condition are and who will be responsible for clearing each

condition. This will include identifying the information that will

be required from the EPC contractor to satisfy each condition,

and what work activities will be predicated on FERC clearing

each condition.

The IP teamwill start to strategise a plan for resolving any

issues that may be found to surround DEIS conditions. For

example:

Any conditions that may be impractical to achieve within

the timeframe required by FERC.

Any conditions that may pose unintended safety, reliability,

operability, or maintenance concerns.

Any condition that may be satisfied by an equivalent

mechanismother than as prescribed in the DEIS/EA.

Next, the IP teambreaks down the EPC contractor schedule

to identify ‘packages’ (or ‘work scopes’) for construction

sequences and identifies the applicable FERC conditions

associated with each ‘package’ and the necessary engineering

design information to clear each condition.

Then, the IP team reviews the EPC contractor’s schedule for

producing this information and estimates the timeframe for

FERC to review this information and issue data requests.

The teamestimates the timeframe to respond to these

data requests and eventually authorise construction of the

package, and compares when the EPC contractor needs

to start construction on that package to ensure that there

is acceptable alignment between the schedule to produce

the engineering designmaterials and when authorisation is

needed to construct.

Finally, if there is acceptable schedule alignment, then the

IP teamputs together an executable package. If there is not

acceptable schedule alignment, then an iterative process is

taken where changes aremade until alignment is met. These

changes can include dividing the work package into separate

parts to better match engineering vs construction schedules,

re-visitation of engineering schedules to see if engineering can

be accelerated, or re-visitation of construction schedules to

validate construction ‘need-by’ dates.

Ideally, the IP teamwill develop the following:

An initial implementation plan with a strategy on how the

project is going to incorporate all permit conditions into the

execution phase.

Initial definition around all initial site preparation packages.

Initial definition around all early construction packages, with

a good framework in place to help define future construction

packages, recognising that overall schedules often change.

Construction package

development

Essentially, all initial site preparation and construction packages

contain the following core components:

A description of the scope of work being requested for

approval for construction.

Identification of all of the conditions in the order that are

applicable to the scope of work being requested.

All necessary engineering design information required to

satisfy the conditions associated with the scope of work and

any additional information necessary to support any changes

or deviations from information originally submitted to FERC

associated with the scope of work.

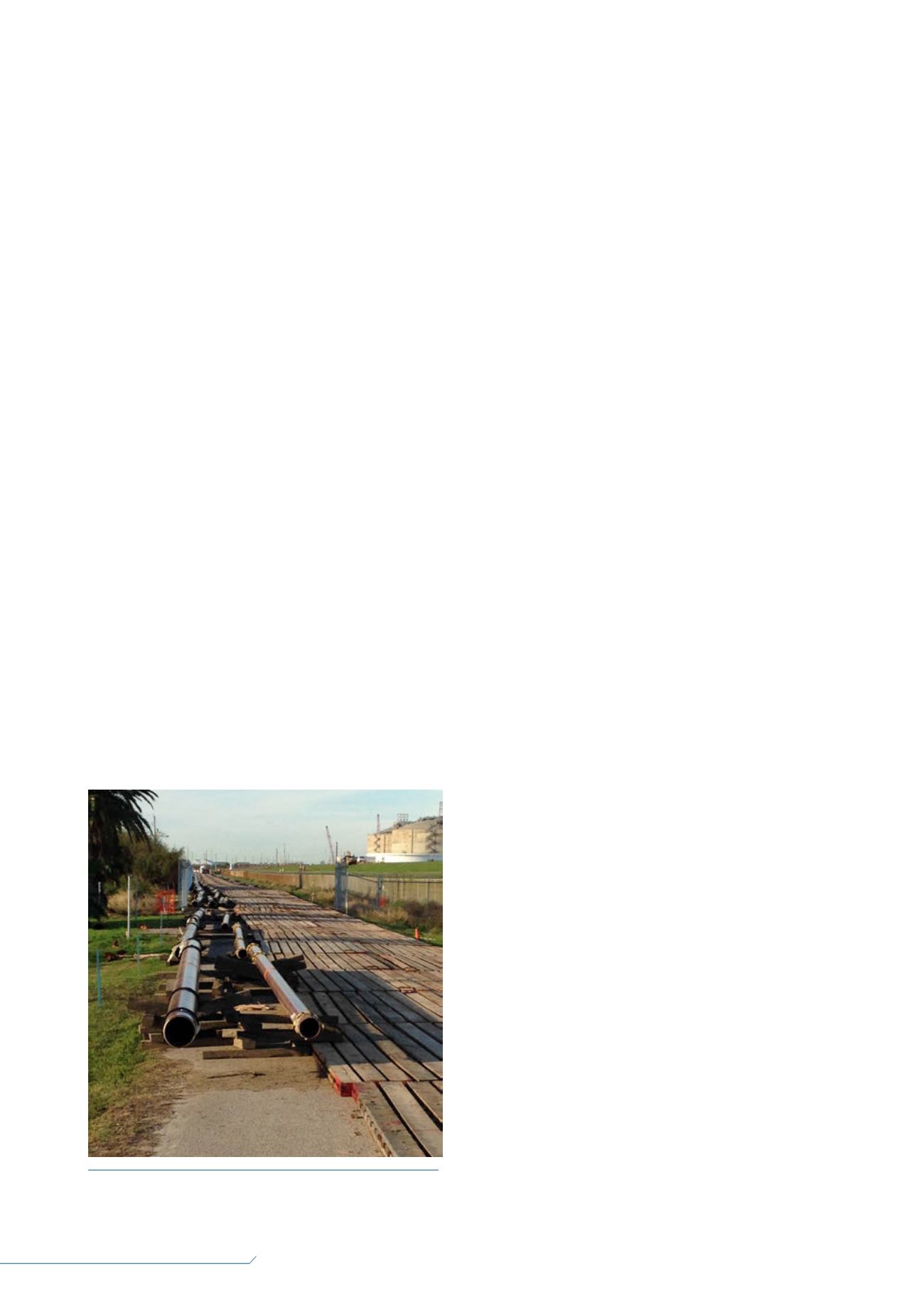

Figure 2.

Initial site preparation. Image courtesy of

Freeport LNG Development L.P.