34

LNG

INDUSTRY

APRIL

2016

the steam plant auxiliary boiler. Together, this system enables

recovery and reliquefaction of the low temperature BOG, while

minimising compression losses.

Amodular construction approach allows repeatability with

respect to the liquefaction trains. Use of a modular fabrication

approach translates into inherently safer construction sites and

reduced on-site labour and associated temporary facilities, while

providing a high degree of quality and schedule control.

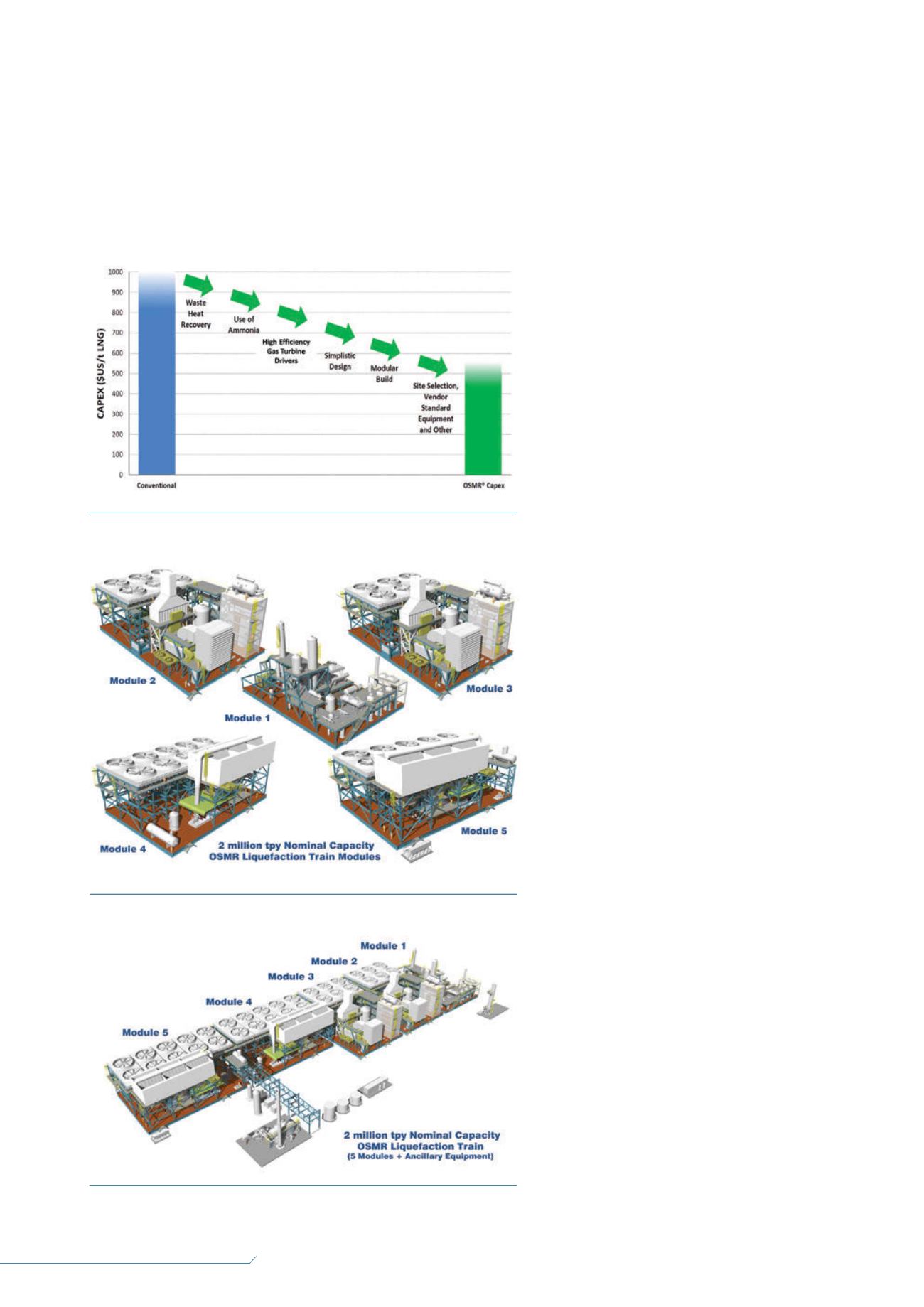

Figure 1 illustrates the component capital cost savings from

applying the company’s liquefaction process design andmodular

construction.

Why ammonia?

The selection of ammonia as the precooling refrigerant is a

significant element of this process technology. Ammonia is a

commonly used, environmentally friendly, naturally occuring and

efficient industrial refrigerant. It has a lifecycle in the

atmosphere of less than one week and, therefore,

has a global warming potential (GWP) and an ozone

depletion potential (ODP) of zero.

When compared to commonly used propane

precoolant, the use of ammonia in refrigeration

cycles demonstrates excellent thermodynamic

qualities, resulting in excellent efficiency and,

therefore, reduced emissions from the power

generation required for refrigeration.

Compared to propane, anhydrous ammonia

vapour is harmful in relatively low concentrations.

Despite this important consideration, whichmust be

managed effectively, ammonia has the following

characteristics:

It is not readily flammable or explosive.

It has a molecular weight of 17.0 and is lighter

than air (molecular weight of 29), so it tends to

rise and naturally dissipate. High volumetric air

flow from the air coolers within the company’s

liquefaction trains assists in the dissipation of

any ammonia vapour present.

Ammonia releases can be readily detectable at

relatively low concentrations.

Importantly, mitigation of ammonia release

exposure is reliable and effective through simple

application of automated detection systems,

automatically isolatable sections, and water

sprays due to ammonia’s high affinity and

solubility in water.

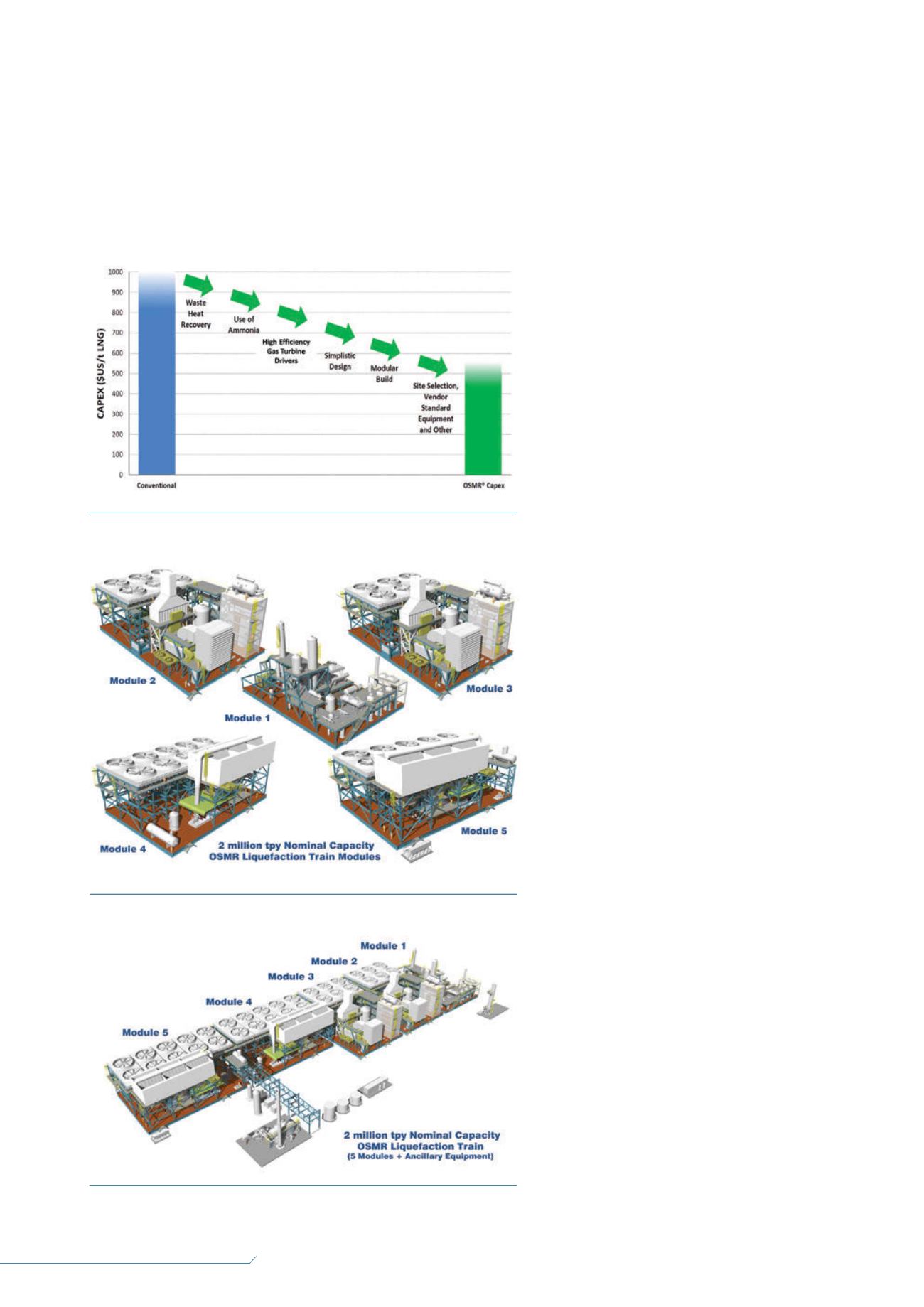

Modular construction

The liquefaction process technology’s compact

mid scale design configuration allows each LNG

train to be broken down into only fivemain process

modules, as shown in Figure 2. Offsite fabrication

of themodules in a specialty fabrication yard, with

transport to the project site via ocean-going barge

or specialty carrier, represents the construction

base case strategy. This modular approach is safe

and reduces onsite labour, whilst providing a high

degree of quality and schedule control during

module construction. Themodular construction

approach allows repeatability with respect to the

liquefaction trains.

Delivery of the process modules to the site in a

pre-determined sequence allows optimised

assembly of the LNG train, as shown in Figure 3. A

material offloading facility (MOF) and a heavy haul

road enable transfer of themodules from the barge

to the final position, using self-propelledmodular

transporters (SPMTs).

Figure 1.

Optimized Single Mixed Refrigerant (OSMR

®

) CAPEX

improvements chart.

Figure 2.

Schematic of modules.

Figure 3.

Schematic of assembled modules.