38

LNG

INDUSTRY

APRIL

2016

This article discusses some of the design features of the

all-electric liquefaction facility, focusing on the benefits and

challenges from an operator’s perspective.

Driver selection: maintainability

in focus

In a large scale LNG plant, refrigerant drive power can be provided

by using electric motors, gas turbines or steam turbines.

The electric motor driver option selected by Freeport LNG is

efficient, reliable, simple to operate, and offers a long period

between twomaintenance events, as well as minimum air

emissions. The other inherent advantages of this option are

reduced seasonal fluctuations in power available to the

refrigeration compressors and a higher breakaway torque.

Steam turbine drivers were not considered for the project. On

the gas turbine side, single-cycle industrial gas turbines have low

efficiency, although it is possible to improve their heat rates with

the addition of heat recovery steamgenerators (HRSG). Their

operation would bemore complex and result in higher levels of air

emissions.

The use of aeroderivative gas turbines with higher efficiency

was another viable option. Themain drawback is that their

generated power decreases with ambient temperature sharply. In

a location that has hot summers, such as the US Gulf Coast,

power reduction will negatively impact LNG production. Options

for augmenting aeroderivative power with air inlet cooling

systems to achieve a relatively flat power profile increases

operational complexity, and augmented horsepower is expensive.

Typical data for comparing industrial gas turbines, aeroderivative

gas turbines andmotors with load-commutated inverter (LCI)

drive are shown in Table 1.

Lifecycle cost

The CAPEX for an electrically-driven LNG plant would be higher

than for a gas turbine driven facility. This is mainly because of

the cost associated with power generation equipment, but the

Freeport LNG project has decided to import 90%of its required

power from sources outside of the plant boundary. Importing

most of the required power helped tomanage project CAPEX

significantly.

Electric drivers can savemillions of dollars in annual OPEX by

cutting fuel gas, providing higher availability and reducing carbon

taxes. In a typical three-train 15million tpy gas liquefaction facility,

with the assumption of 200MWof power required per train, gas

turbines would consume enough natural gas to produce over

1 million tpy of LNG. Furthermore, because of fewer outage days

and consistent power levels during hot summers, the

electrically-driven plant will easily produce the equivalent of

10 – 15 days more of LNG per year.

Finally, while carbon taxes are not

assessed at the Freeport LNG facility, if

one assumes that a tax of US$30/t of

CO

2

could be assessed against such a

facility, total tax reduction would

amount to over US$10million/yr.

Reducedmaintenance costs are

another itemon this list. It is estimated

that themaintenance cost of an electric

drive is approximately 30%of the

maintenance cost of a gas turbine drive.

All-electric

liquefaction facility

The overall power requirement for the

three-train liquefaction facility will be

approximately 660MW, which will be

supplied from the public grid system

through two new 138 kV, 4000 A

circuits. A new substation

will be installed adjacent

to the liquefaction facilities

with a four-breaker outdoor

arrangement.

The new substation

will be the primary power

distribution point and will

include gas insulated

switchgear (GIS) of the

two-bus type with the GIS

feeder breakers installed

indoors. Additionally, the

existing power system at

the LNG import terminal

will remain in operation.

Within each LNG train,

one 138 kV circuit will

connect directly to the

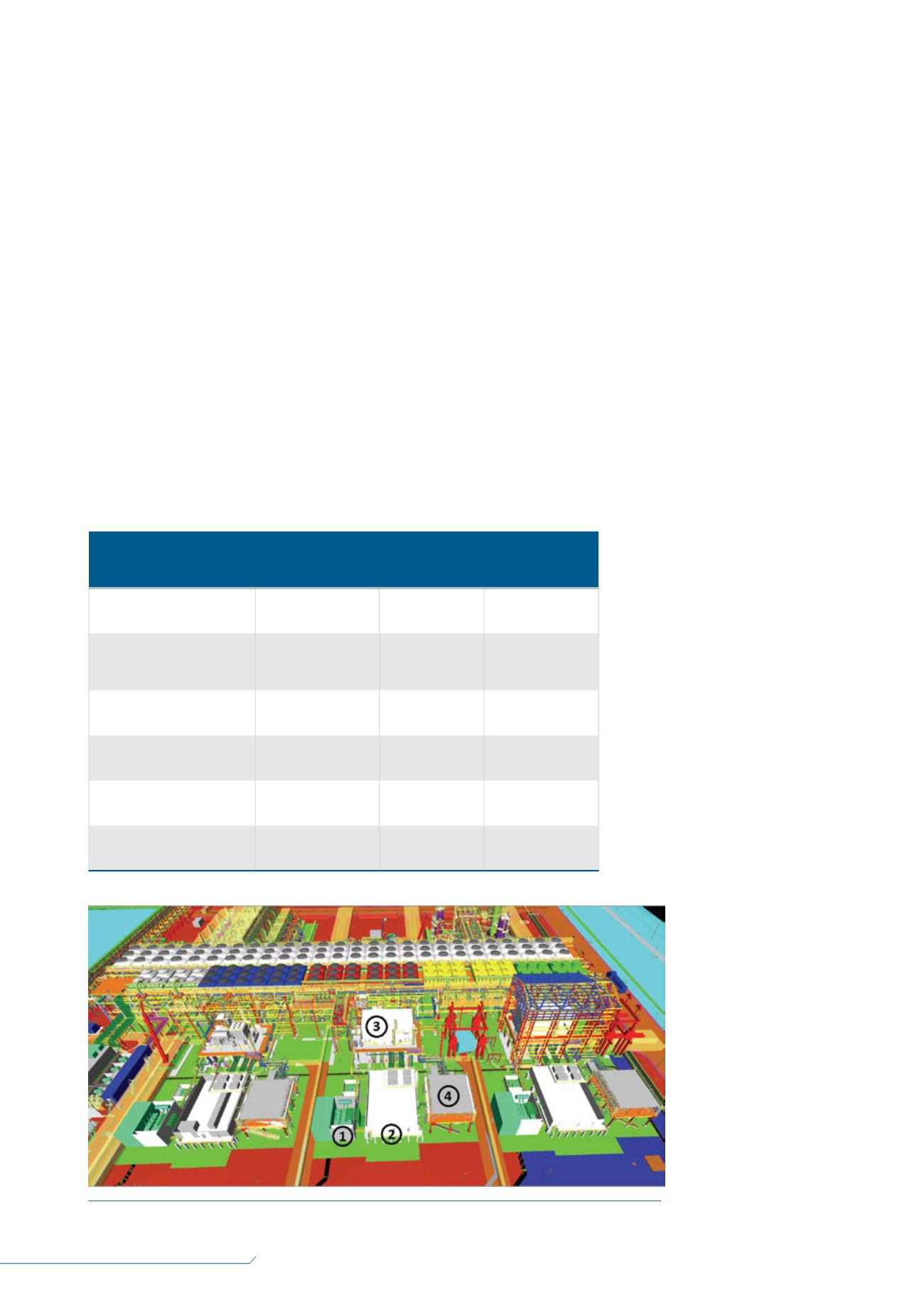

Table 1.

Typical data for comparing industrial gas turbines, aeroderivative gas turbines

and motors with LCI drive (data may vary depending on manufacturer and site particular

conditions)

Industrial gas turbine Aeroderivative

gas turbine

Motor with LCI

drive

Number of days down per year

(averaged to cover all minor

and major maintenance plans)

7 – 10

2 – 4 (assume

engines are ready

for swap)

2 – 4

Average driver efficiency

30 – 35%

40 – 42%

94%

High ambient temperature

sensitivty

Power reduces

moderately

Power reduces

sharply

No power reduction

Number of operating hours

before minor maintenance

12 000

4000

24 000

Number of operating hours

before major maintenance

24 000

24 000

48 000

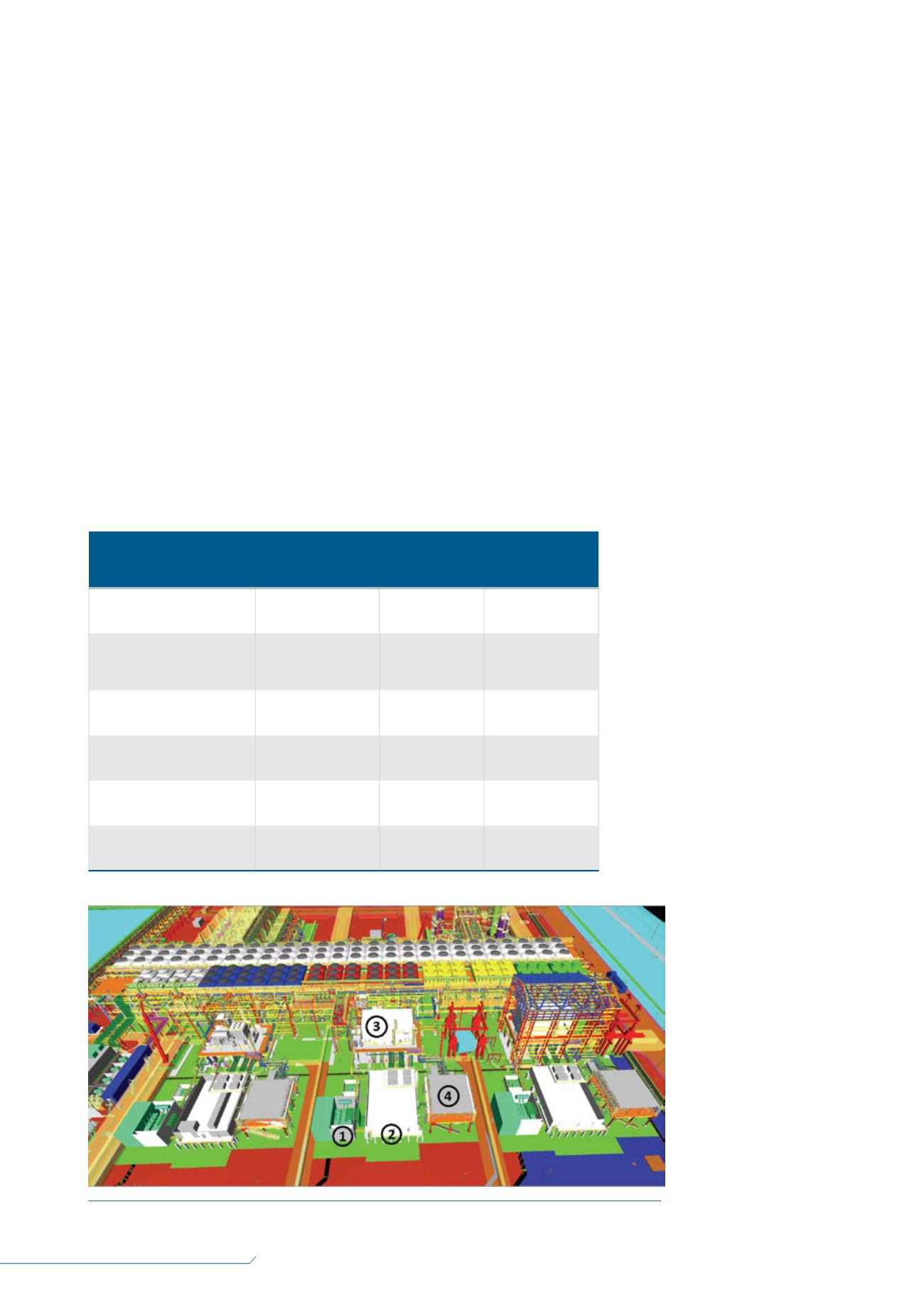

Figure 1.

3D model of the facility showing three compressor strings within one liquefaction unit.