46

LNG

INDUSTRY

APRIL

2016

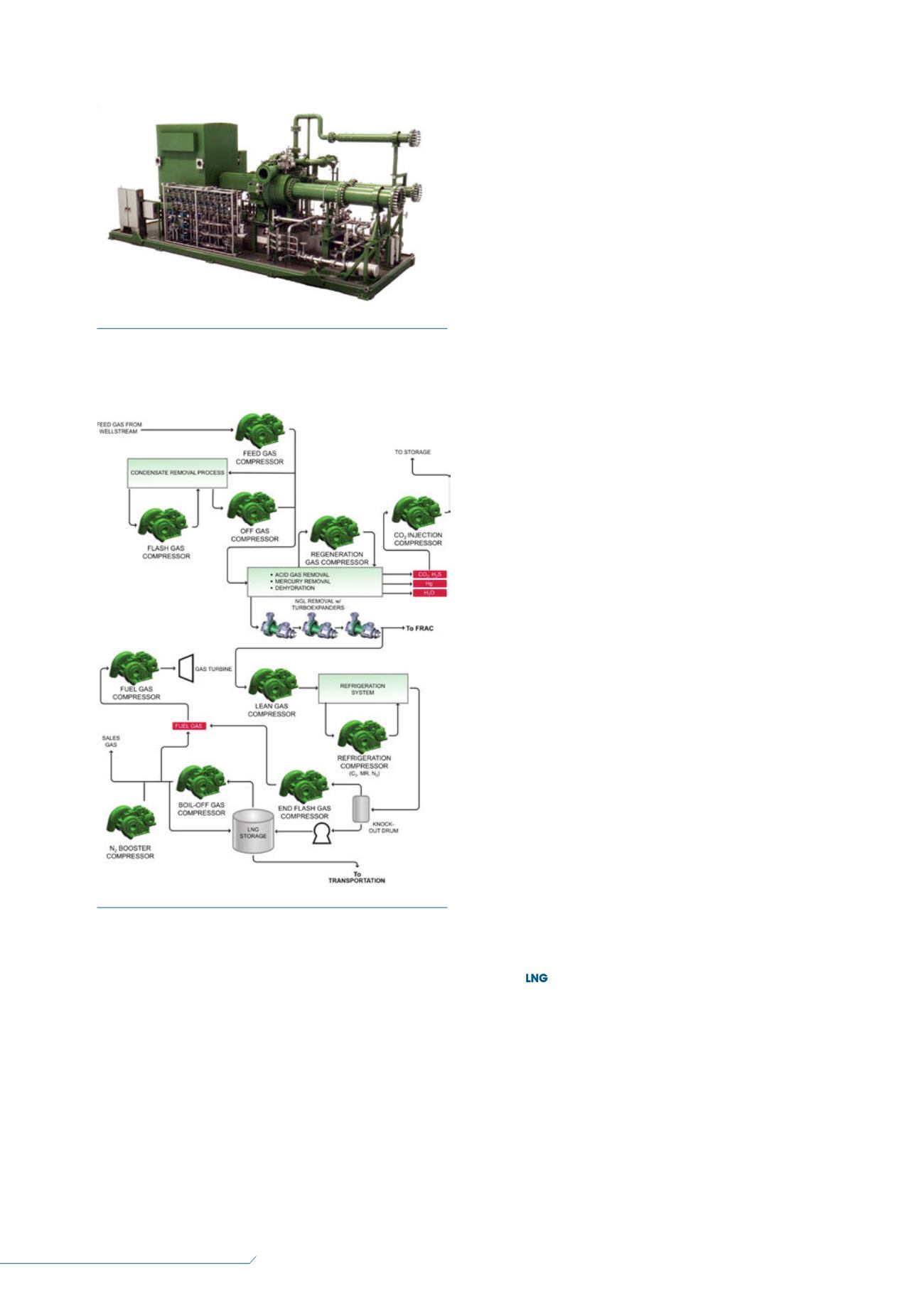

scope, the contract required integrated API 617/614

features, including an on-skid lubrication system, which

fed the compressor and main drive motor, tandem

dry-face seals, the seal support system, and a custom

integrated control system.

The integrated seal support system was fully

engineered and fabricated in-house by the compressor

OEM. This integration of the seal support system

included complete tubing to and from the dry-face seals

prior to shipment. By having the OEM both design and

supply the seal support system, potential field fit-up

issues were eliminated along with the potential for site

work delays associated with the seal system. Figure 1

depicts an integrated skid design for a typical MR

IGC compressor. Based on the client’s requirements for

minimising the assembly work in the field, the

compressor core unit, lubrication arrangement, seal

support system, instrumentation rack, and

customer-supplied controller were all integrated on a

common base, and were able to ship in place for ease of

transportation and installation. It was estimated at the

time of shipment that the total commissioning time for

the skids would be reduced by 30 – 40% compared to

an arrangement fully erected at site.

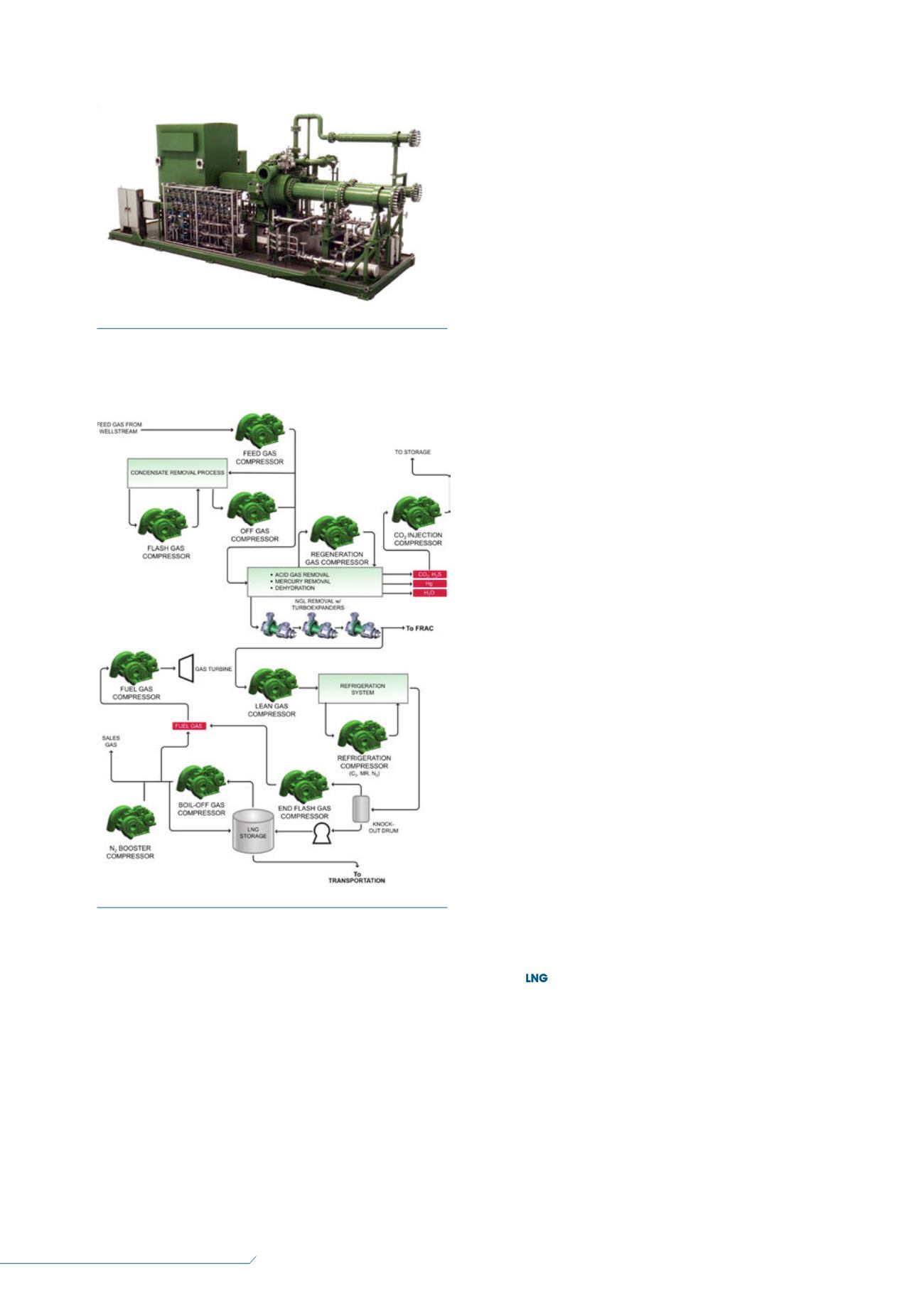

LNG applications

It is important to note that IGC compressors have been

increasingly selected by LNG engineering, procurement

and construction (EPC) contractors and end-users for

their flexibility in design, reliability, efficiency, and

expedited delivery. Since the completion of this project,

IGC compressors have continued to gain on alternative

technology in this growth space. Subsequently,

portfolios continue to expand with players specifically

developing products that can handle more flow,

increased power, and higher pressure, and that fit into

new applications and can be easily mobilised. Within the

liquefaction process, there are a variety of compressor

applications in which IGC compressors are a good fit

(Figure 2).

A bright future

The authors expect application-specific compressor

offerings to continue to mature and evolve, in line with

the small scale LNG market. Some of the expected

developments include additional standardisation in

OEM product offerings for various applications, modular

designs for ease of transportation and installation, and

partnerships with EPCs to align OEM products with

standardised plant offerings.

The number of successful plants utilising

IGC compressors for MR applications continues to

increase at an accelerating pace due to the reliability

and wide market acceptance that the technology offers.

This successful project is yet another example of how

IGC compressor OEMs are leading the industry towards

a faster, more efficient and ultimately more profitable

way to engineer, design and operate small scale LNG

plants.

References

1. BEATY, P. J., EISELE, K., MACEYKA., T. D., and

SCHWARZ, C. ‘Integrally Geared API 617 Process

Gas Compressors’, paper presented at the 29

th

Turbomachinery Symposium, (September 2000),

Houston, Texas, US.

2. BLOCH, H. P. and GEITNER, F. K., ‘Use Equipment

Failure Statistics Properly’,

Hydrocarbon Processing

,

(January 1999), pp. 49

–

53.

3. GRABAU, D., ‘Use Integrally Geared Compressors

for Small-Scale LNG’,

Hydrocarbon Processing

,

(October 2013), pp. 25

–

28.

Figure 1.

A three-stage MSG

®

-8 integrally geared centrifugal

(IGC) compressor serves the main cryogenic heat exchanger

refrigeration loop in a liquefaction process.

Figure 2.

A simplified diagram of the liquefaction process,

demonstrating potential applications for IGC compressors.