50

LNG

INDUSTRY

APRIL

2016

Unloading: all 2/3 compressor units run in parallel.

Holding: one unit runs under bypass control.

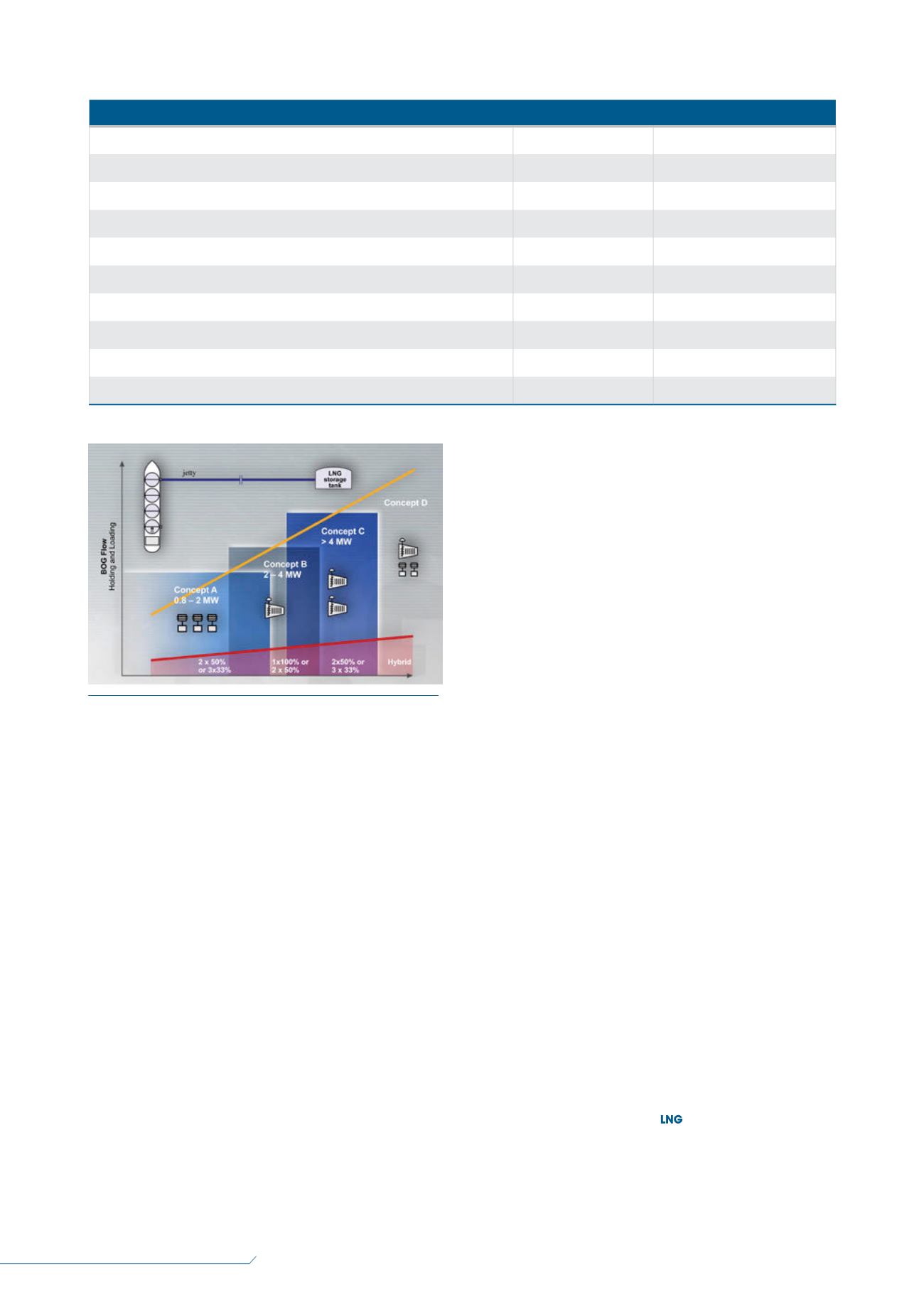

Concept B (most commonly used):

1 x 100% (no spare unit) or 2 x 50% single-casing,

single-shaft centrifugal compressor.

Unloading: compressor unit runs at high IGV setting.

Holding: compressor unit runs at a minimum IGV setting

in automatic start/stop frequency, leading to the most

economic plant operation.

Special note: for offshore installations, such as an LNG

carrier converted into an FSRU, the holding BOG flow

is used to fuel the steam boilers for the onboard steam

turbine driven power generators.

Concept C:

2 x 50% or 3 x 33% single-shaft centrifugal compressor

packages.

Unloading: compressor units run in parallel at high IGV

settings.

Holding: one compressor unit runs at different low IGV

settings.

Concept D (hybrid):

1 x 100% (ship unloading compressor) single-casing,

single-shaft centrifugal compressor running with high

IGV setting during ship unloading, plus two small

customised reciprocating compressors covering the

holding mode

Unloading: single-shaft centrifugal compressor runs at

high IGV setting only during LNG tanker unloading.

Holding: small customised reciprocating compressor runs.

It is important to understand that the optimised BOG

recovery concepts for LNG import terminals require

compressors that are capable of direct online start/stop

operation in order to avoid compressor cool-down with

associated gas flaring, as well as utilising reciprocating

compressors suitable for cryogenic gas applications.

Key design features for this achievement are the

turbo-type compressor design, material selection and

combination for cryogenic service, dry gas seals encapsulated

in heated seal carriers, and an adjustable IGV compressor

control system.

Single-body, single-shaft BOG centrifugal compressors are

customised for exactly this purpose, as they are specifically

designed and engineered for maintenance-free, intermittent

(start/stop) operation from ambient, as well as from cold

conditions, without any special cool-down procedures.

These unique features make the units the best technical and

most reliable fit, and provide the highest possible start-up

availability customised for the needs of today’s state-of-the-art

LNG import and export terminals.

Conclusion

The demand for safe, efficient and cost-effective compression

systems for handling BOG on both carriers and LNG receiving

terminals is greater than ever before. This means that

maximum BOG flows are increasing and require a custom

engineered compressor solution (or configuration).

This scenario uses the advantage of cold gas reciprocating

compressors for low-flow handling and turbocompressors for

higher loads, which goes beyond the application range of

reciprocating BOG compressors.

Reference

1. ‘World LNG Report 2015 Edition’, International Gas Union,

/

IGU-World%20LNG%20Report-2015%20Edition.pdf

Figure 5.

The application range of different compressor types

in receiving terminals.

Table 1.

BOG sources – a typical case study

Source of BOG

Unloading mode (kg/hr)

Holding mode (kg/hr)

Flash due to ship cargo tanks operating at higher pressure than onshore LNG tanks

3600

–

Pumping heat from unloading pump

20 000

–

Unloading line heat leak (with 20% added for fittings, expansion loops, etc.)

1700

–

LNG tanker (ship) cargo tank heat leak

6000

–

Onshore LNG tanks heat leak

2000

2000

Vapour return to ship cargo tanks

(22 000)

–

Negative displacement due to LNG sendout

(1300 variable)

(1300 variable)

Displacement from LNG tanks due to unloaded LNG

22 000

–

Total

32 000

2000 maximum. Down to zero