58

LNG

INDUSTRY

APRIL

2016

shipowners need to be confident that they can purchase and

load the fuel on board safely and efficiently when and where

they need it.

All of the current LNG as fuel projects depend on one-off

LNG bunker arrangements, with fixed suppliers delivering gas

either from fixed terminals or using trucks. To build a wider

and deeper LNG bunker chain (similar to the highly flexible

bunker chain that ship owners using oil can depend on), LNG

needs to be widely available and capable of being loaded

onto ships in a safe and standardised way. Furthermore, the

quality and quantity of the fuel needs to be accurately

measured.

Classification societies play a strong role in helping

develop this bunker chain and facilitating the shift to gas.

They can help develop guidelines and standard safety

procedures, validate measurement protocols, and can carry

out studies and audit the outcomes for determining what is

safe and what is not. They can also work with operators and

shipyards to develop new types of vessels specific to LNG

bunkering, and can ensure that ships are ready when the

economic case for LNG becomes more interesting.

What is needed?

Ships that may switch to LNG fuel in the future need to be

laid out, built and equipped to bunker LNG fuel safely and in

a standardised way. A new breed of small scale LNG tankers,

which can carry large cargoes of LNG for significant distances

and then deliver the fuel quickly and safely to ships, are

also needed. Standards are required for the couplings and

procedures, which will make training in, monitoring of and

the operation of LNG bunkering as simple, safe and routine

as bunkering oil fuel is today. Furthermore, agreement on

measuring and analysing gas bunker quantities and qualities

is needed to allow an open market in LNG as fuel to develop

commercially.

Future-proofing

However, first and foremost, the appropriate vessels need

to be built. Bureau Veritas (BV) has published requirements

for ships that are designed and fitted out for dual-fuel or

LNG fuel propulsion, but which are not initially intended

to use LNG as a fuel. The requirements, which are set out

in Rule Note NR 627 Gas-Prepared Ships, cover special

arrangements for new ships that are designed with specific

arrangements to accommodate the future installation of an

LNG fuel gas system.

Many owners consider that they will switch to LNG as a

fuel in the future, but are not yet ready to make that change.

Therefore, it makes sense to build and lay out ships so that

they can easily be converted in the future. The requirements

of this notation set a benchmark for designers and yards so

that they can ensure that every ship is future-proofed and

able to be easily converted to LNG as a fuel when the market

conditions are right.

Logistics

Transporting LNG to where it is needed and building flexibility

into the LNG as fuel supply chain requires a new breed of

vessel. While bunker oil is widely available from quaysides,

there are currently few LNG terminals that can deliver gas as

fuel, and no ports where LNG delivery is feasible from high

speed fixed installations on the quayside during routine cargo

and passenger operations. So, with a relatively small number

of LNG terminals and a small market of ships for the fuel, the

first movers into the LNG bunker chain will need relatively

large bunker vessels, which can move quickly and cover large

areas.

Before anyone can design and build these vessels, they

have to be sure that they will be safe. This is where

classification societies come in. For instance, BV set out

requirements in Rule Note NR 620 LNG Bunkering Ship,

covering special arrangements for ships carrying LNG that will

transfer that LNG to LNG-fuelled vessels. These rules help

ensure the safe development of this new type of ship.

NR 620 covers the design and installation of the LNG

transfer systems from bunkering ships to the receiving ship,

as well as the vapour transfer system from the receiving ship

to the bunkering ship, including LNG hoses, transfer arms and

auxiliary systems for handling the LNG system. The design

and installation of the equipment intended for boil-off gas

(BOG) management and the gas piping system on the

bunkering ship are also set out. There is a separate section on

safety arrangements.

The first LNG bunker tankers

Rotterdam-based Anthony Veder has built a fleet of highly

flexible small gas carriers under BV class and, although

these are built for LNG/LPG/LEG transport and distribution,

they also have the capacity to act as LNG bunker tankers.

It is likely that the 6500 m

3

Coral Anthelia

will be the first

vessel actually deployed as an LNG bunker tanker, working

on charter to Norway’s Skangas to deliver LNG as fuel in the

Northern North Sea/Baltic areas from 2016.

The first purpose-built LNG bunker tanker is being built to

BV class at Hanjin, South Korea, for a joint venture (JV)

between Japan’s Mitsubishi Heavy Industries Ltd and

NYK Line, Fluxys, and ENGIE. The vessel will have two Type C

tanks with a capacity of 5000 m

3

of LNG built into a 108 m

hull powered by twin dual-fuel engines, giving it a speed of

approximately 13 knots. A full set of thrusters will make the

vessel highly manoeuvrable and allow it to have a high

bunker delivery rate. There will be an onboard chromatograph

to measure the exact quality and energy content of the gas

delivered.

The vessel is expected to enter into service at the end of

2016 and the first client has already been contracted. United

European Car Carriers (UECC) will use the ENGIE tanker to

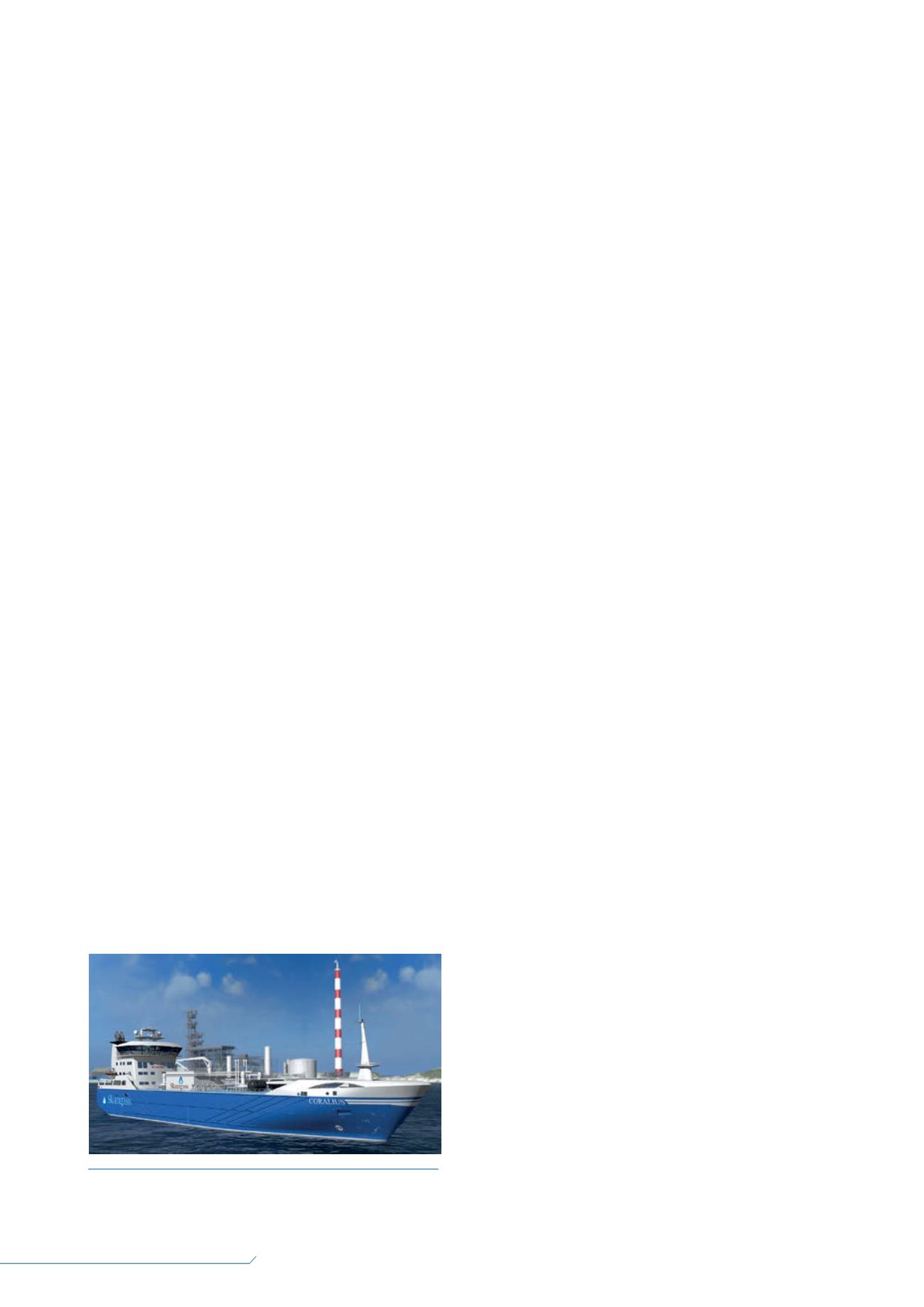

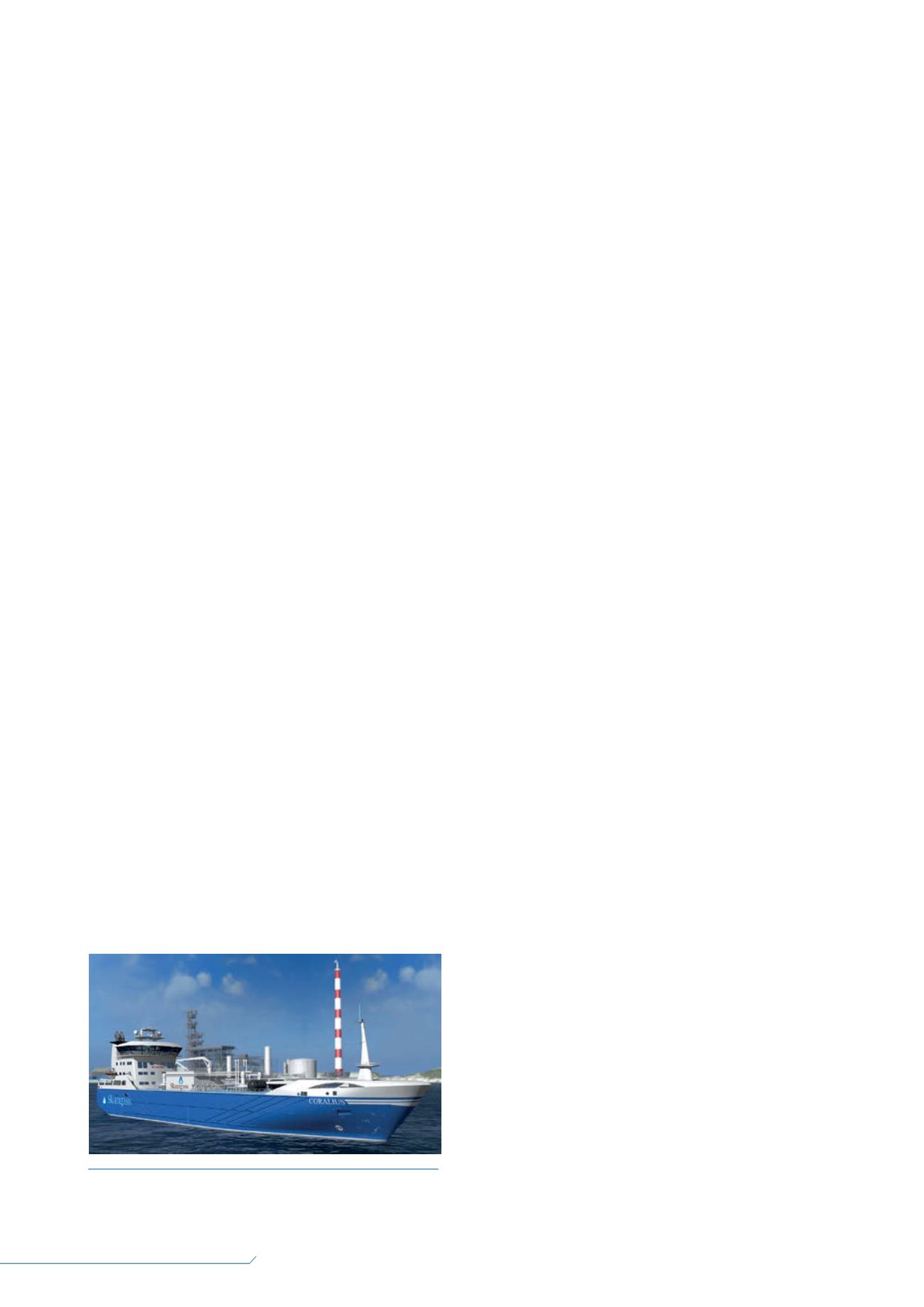

Figure 2.

The

Coralius

5800 m

3

LNG bunker tanker being built

to BV class for Skangas.