62

LNG

INDUSTRY

APRIL

2016

It was partly funded by the EU through the TEN-T network,

and aimed to draw up and provide guidance on the installation of

an LNG bunkering network.

After a European call for tender, the contract was awarded to

Marine Assistance – a ship design and marine engineering office

– and Axe Environnement – a consulting engineering company

specialised in industrial risk analysis.

The main aims of the study were the following:

Assess the risks involved in LNG bunkering by trucks, bunker

vessels or shore tanks.

Define local rules for bunkering operations.

Assess the local LNGmarket.

Evaluate putting in place a proper LNG logistic scheme.

Risk analysis

LNG bunkering is a newmethod that appeared along with the

first gas-fuelled vessel (but not methane carrier), the

Glutra

, in

2000.

Bunkering LNG is not entirely different from bunkering fuel

oil, but has two notable exceptions: LNG is stored at cryogenic

temperatures and has an extremely low flash point. The main

risks associated with transferring LNG are flash fire and a

cryogenic hazard that can lead to burns, or to steel becoming

brittle and prone to fracture on contact.

For the purposes of the study, the risks of different bunkering

methods (trucks, vessels or shore tanks) and of different client

vessels (RoPax, containership, etc.) were evaluated. Several

sizing scenarios were defined based on the latest observations

and trends in the gas-fuelled vessel industry.

These scenarios were then applied to the different Seine valley

harbours. Local port configuration had to be carefully considered

on a case-by-case basis. Depending on the history of each port,

the terminals and quays may be located close to the population

centre, or far away, as in the case of themost recently built

terminals.

Bunkering scenarios

In order to cover most of the likely situations, different bunkering

scenarios were defined. These scenarios were based on LNG

bunkering/transfer methods observed throughout the world in

2015.

Typical bunkering scenarios always include the following:

A client: the ship that will receive LNG as bunker fuel.

A bunker tank: bringing and transferring LNG to the client.

A bunkeringmeans: devices used to transfer LNG from a

bunker tank to the client tank. In 2015, the available devices

were flexible hoses and articulated arms.

Safety devices: this refers to all safety equipment fitted to

ensure the safe transfer of LNG.

Dozens of potential scenarios involving different combinations

of tank types, safety devices and bunkeringmeans are possible.

This article will evaluate twomain bunkeringmethods:

truck-to-ship bunkering and ship-to-ship (STS) bunkering.

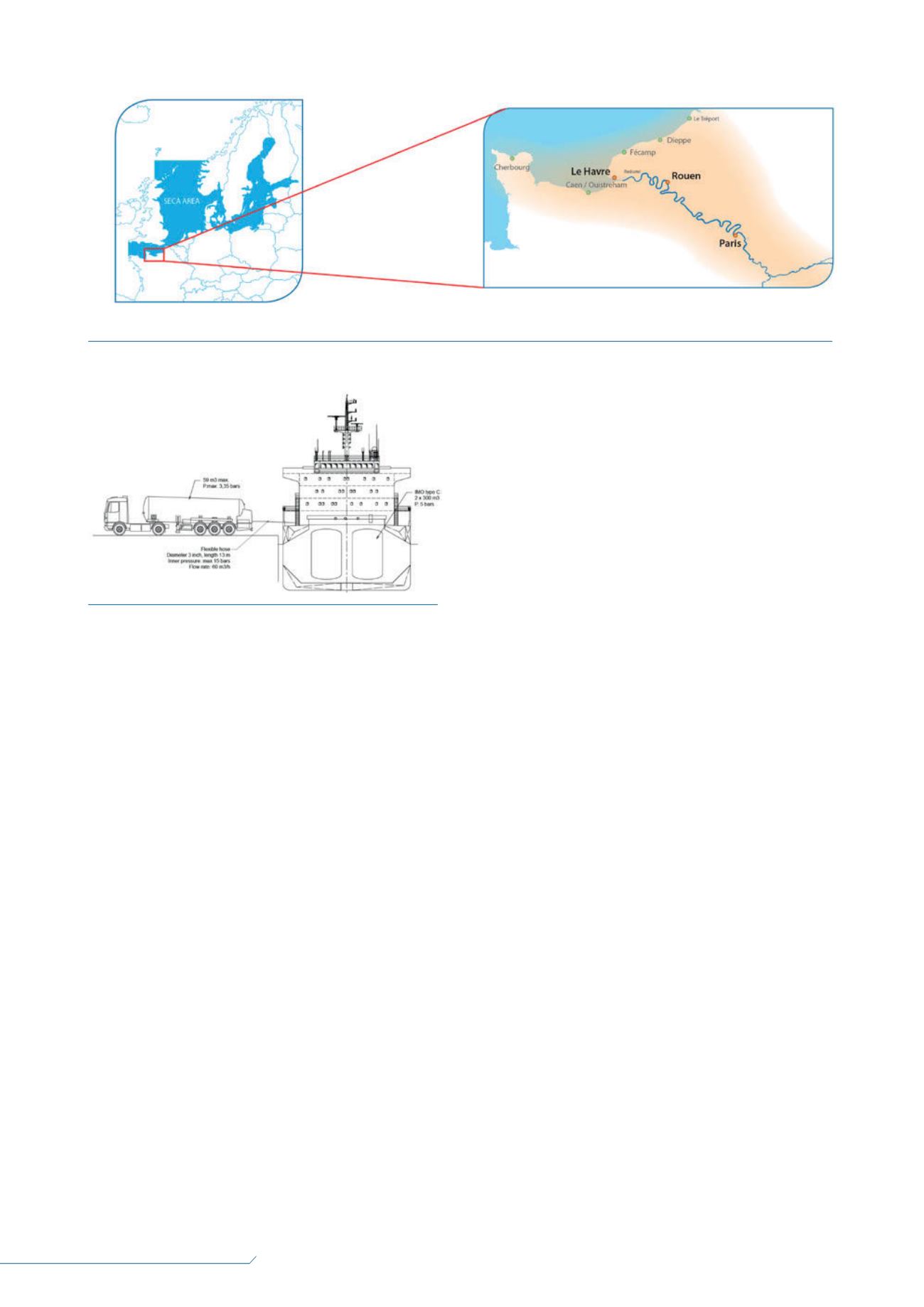

Truck-to-ship bunkering

In 2015, truck-to-ship bunkering was themost commonmethod

of fuelling LNG ships as it provided a flexible and inexpensive

solution. The following describes the equipment used in such

transfers, as well as operational data (Figure 2):

Client vessel:

Typical vessel type: car-ferry, dredger, support vessel, small

cargo vessel or tankers, etc.

LNG tank: IMO Type C, 2 x 300m

3

.

Inner tank pressure: 5 bar.

Bunker truck:

LNG tank: vacuum insulated tank (inner tank stainless steel,

outer tank steel).

Volume: 59m

3

.

Inner tank pressure: 3.35 bar maximum.

Transfer of LNG via hydraulic pump.

Figure 2.

Truck-to-ship LNG bunkering scheme.

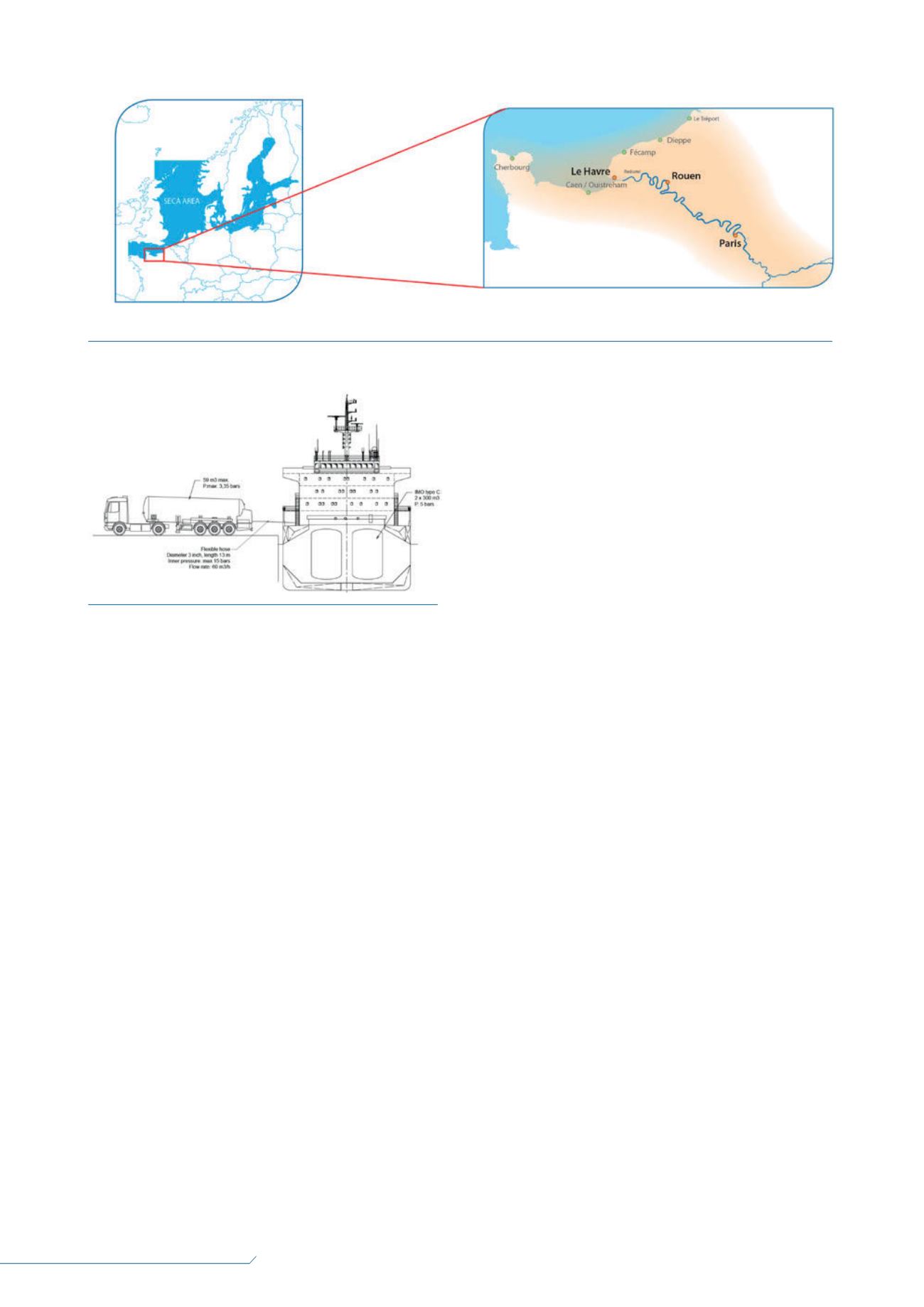

Figure 1.

Seine river valley harbours located at the western side of the European sulfur emission control area (SECA) (credit: Haropa/

Marine Assistance).