70

LNG

INDUSTRY

APRIL

2016

Compared to marine diesel, power generated by

gas-powered engines can lower the emission of NO

X

by 80%

and CO

2

by 25%. The discharge of SO

2

and soot particles is

eliminated entirely when gas-powered engines are employed.

For a cruise season with 34 calls at port and an average layover

time of 10 hr, the reduction of CO

2

, for example, adds up to

320 t.

The LNG hybrid barge is the first floating liquefied gas power

plant. It possesses no propulsion of its own and is towed to its

areas of operations. With a length of 76.7 m, a width of 11.4 m

and a draught of 1.7 m, the barge carries five gas-powered

engines with a total installed electrical output of 7.5 MW. The

gas is supplied from two vacuum-insulated 15 t Type C LNG

tanks. The LNG is provided to the engines in gaseous state by

the gas processing unit (GPU), consisting of an evaporator and a

pressure control system. The barge’s extensive technical safety

equipment essentially consists of the following:

Gas lines made of double-walled stainless steel tubes, gap

filled with nitrogen.

Stainless steel collecting tanks below the LNG tanks.

Ventilation of the engine rooms with a 30-fold air exchange

per hour.

Gas warning sensor system along the gas lines, in the engine

rooms and other sensitive areas.

The principle of cogeneration is employed to generate

electricity, enabling highly efficient operation in accordance with

Germany’s Combined Heat and Power Act (KWKG). In several

stages, the heat of the running engines and exhaust gases is

extracted, achieving a thermal output of 8.8 MW.

The utilisation concept of the LNG hybrid barge consists of

summer and winter operating modes. In winter operating mode,

the barge serves as a stationary combined heat and power plant

and for six months is connected to the electrical supply network

of industry customers, the municipal natural gas network and the

district heating grid. As a self-generator of electricity, the industry

customer receives funding in accordance with the KWKG and a

prorated exemption from the EEG levy.

In summer operation, the gas generators are run to generate

power in 60 Hz and 11 kV operating mode and supply power over

a small onsite distributed generation system (isolated operation)

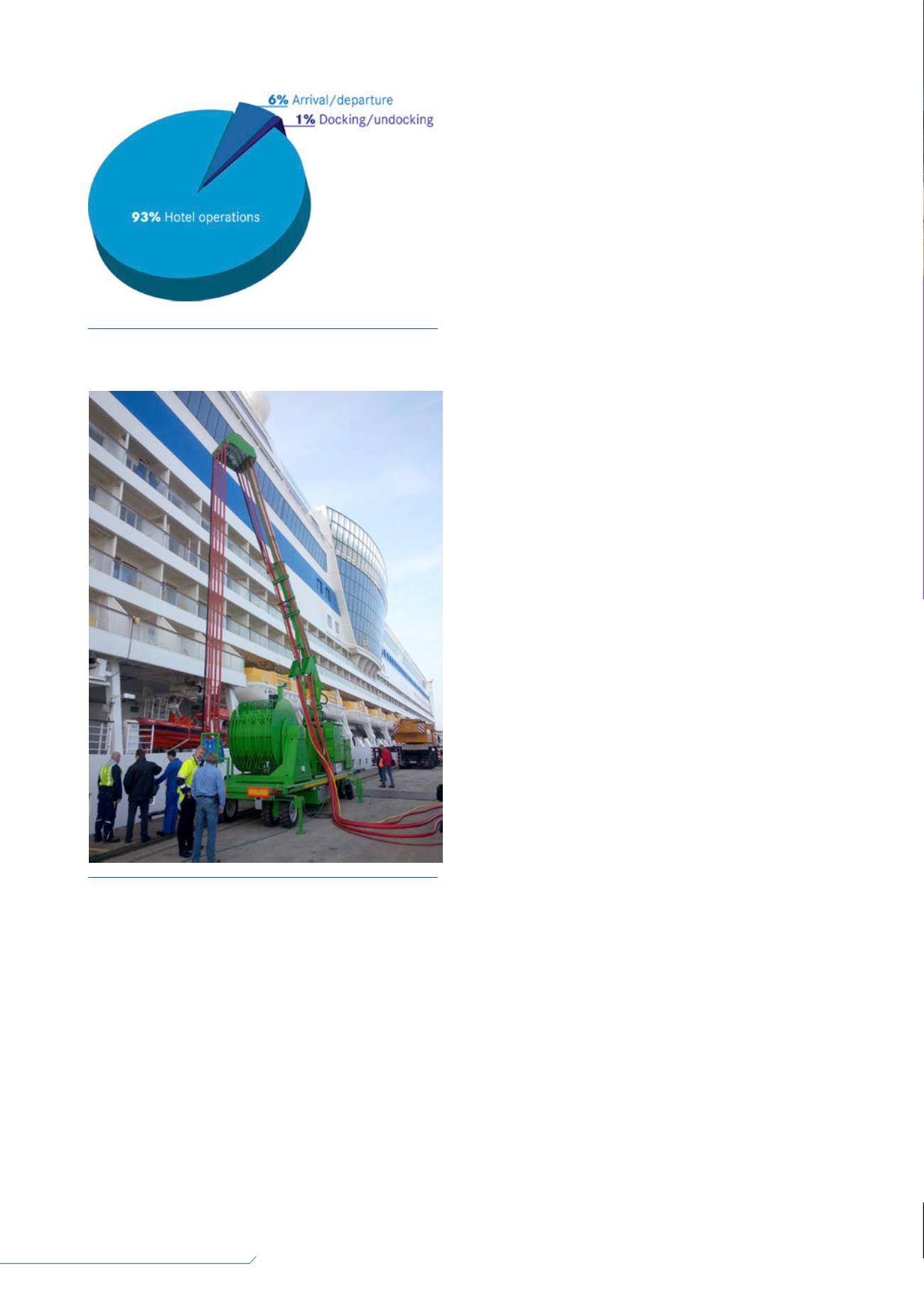

to the cruise ship berths. The transmission of electricity requires

technical solutions that must be safe, mobile and flexible. The

cruise ship is connected to the LNG hybrid barge via eight cables

(Figure 2).

A connector is approximately 650mm long and weighs

around 30 kg. The transfer points, barge onsite distributed

generation system and onsite distributed generation system

vessel must, if required, have the flexibility to compensate for

differences in height caused by tides and also be able to bear the

enormous weight loads of cables and connectors. A two-man

crew is needed onboard to carry and connect the cables.

The cruise ship’s power management system (control room)

sees the barge as an additional engine for generating power. By

slowly powering down and switching off the ship’s engines,

electricity production is increasingly taken over by the barge, until

all of the ship’s engines are completely shut down.

Ships with their own propulsion and carrying fuel must

basically supply themselves, i.e. the technical equipment for

external power procurement is not normally installed. Starting in

2005/2006, pre-equipped and partially equipped cruise ships

have been built and during final outfitting can be equipped with

the necessary technical requirements for the external

procurement of power. For each cruise ship, final outfitting costs

from €500 000 to €1 million and involves a shipyard stay lasting

several days. Without being technically pre-equipped, the

outfitting costs rise significantly and, in economic and technical

terms, may put retrofitting into question.

The year-round utilisation

concept

The development, construction and utilisation concept, as well

as financing, were executed by Becker Marine Systems (it is not

reliant on subsidies or grants). Through its Hybrid Port Energy

(HPE) subsidiary, the company operates the LNG hybrid barge

Figure 2.

Cables and cable handling equipment.

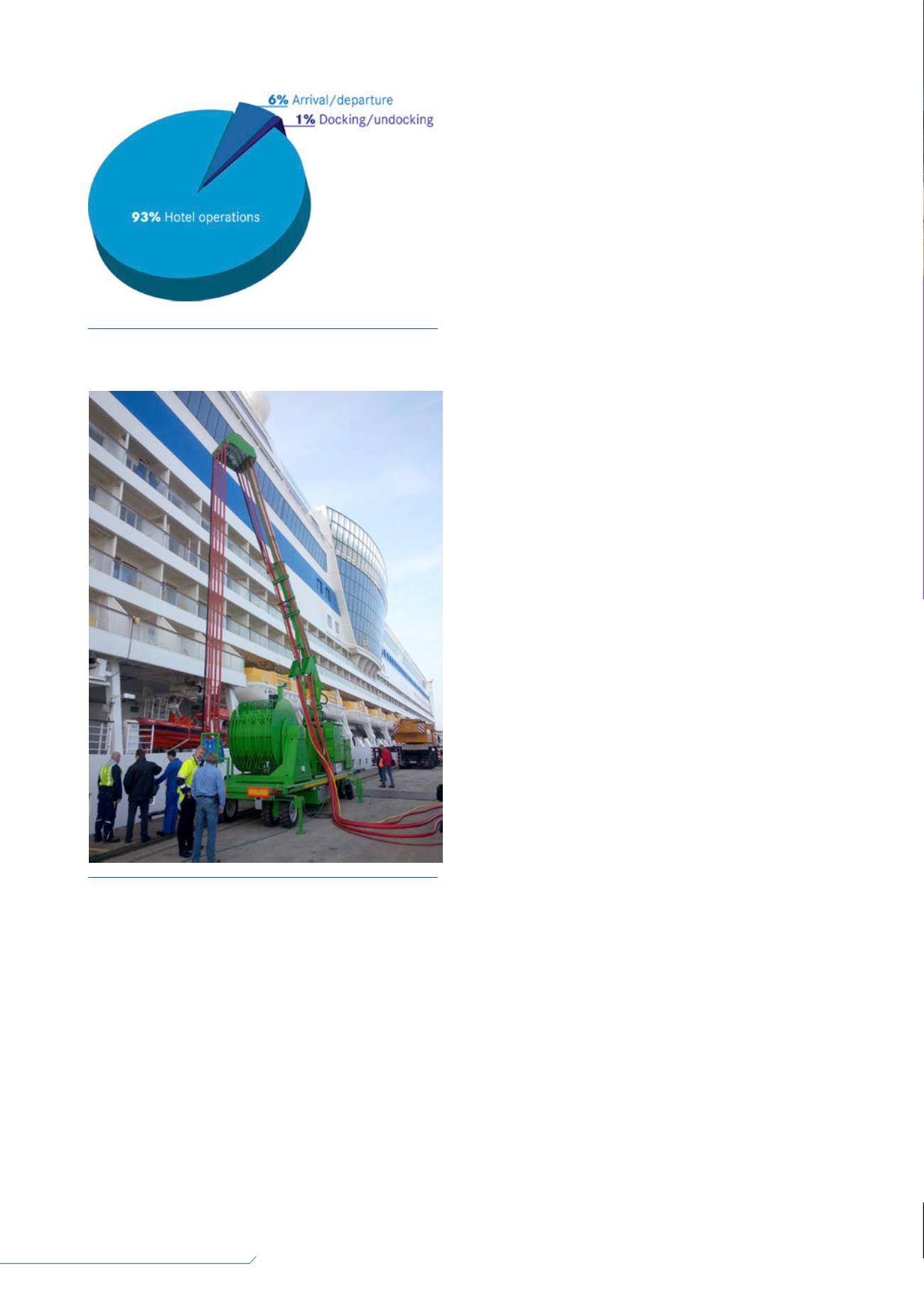

Figure 1.

Graph of the proportions of emissions.