78

LNG

INDUSTRY

APRIL

2016

Abnormal Situation Management (ASM) Consortium and the

Engineering Equipment Materials Users Association (EEMUA 201),

as well as making sure it did not move too fast and cause

confusion. Therefore, it used its existing simulation system and

set up a console to stage the proposed changes, and invited the

shift teams to vote on their preferred HMI option. It was not a

surprise that a compromise was met between the full

ASMConsortium grey and the original graphics (Figure 2).

Operator scope of responsibility was key. It is critical that the

operators’ console only displayed the information and alarms

within their designated scope. This took a lot of education to

move away from the mindset of ‘I need to see all that is going on’

to the understanding of ‘somebody else is dealing with that. I

need to concentrate on my area.’ The systems department

developed overview screens and operator scope that showed the

process rather than the items of the plant, reducing the need for

the operator to build a mental model of the process. Figure 2

shows an example of how a single operator controls ship offload

from a single display, regardless of what area of the plant needs

filling. Historically, this could have needed three operators to

control each of their areas.

Bringing information together

To take full advantage of open systems, Grain LNGworked

to incorporate all standalone systems, such as CCTV, permit

to work, muster role call, work instructions, piping and

instrumentation diagram (P&ID) drawings and process status,

into a single video wall. This enabled the operator to see

information, such as running order of equipment, plant under

permit and isolations, on a single display. Once again, the user

experience was crucial. Grain LNG did not want to produce an

electronic piece of wallpaper that nobody looked at or interacted

with. It needed to be rich in content and simple to use, which was

a considerable challenge due to the infancy of the technology

being used (Figure 3).

Grain LNG opted to use a touch screen controller to

automatically manage the inputs and to switch the operator

keyboard and mouse from their console to the video wall. What

was pressed on the touch panel appeared in front of the station

that pressed it. Together with some pre-configured ‘incident’

layouts, this provides the operators with all of the information

that they require.

Let in the light

Work flows were studied and the building layout was designed

to minimise traffic flow and disruption to the operations

technicians. Visitors have a separate entrance and can only

gain access to the control area via the shift engineer’s office,

empowering the engineer to promote a calm, non-disruptive

environment for the technicians. Once again, small details were

key, and Grain LNG even installed a ceiling-mounted card reader

that allows a technician to open the door with their hands full,

maintaining a secure environment by reducing the temptation to

prop doors open.

The shift engineer’s office has a second function as an

incident control room, complete with smart board and plant

maps incorporated within a custom actuated desk, which allows

users to stand up. This is especially useful for emergency services

personnel whom usually have lots of equipment hanging from

their kit belts.

Natural daylight was high on the operations list of

requirements. Therefore, a large blast-proof windowwas

Figure 7.

Completed main control room.

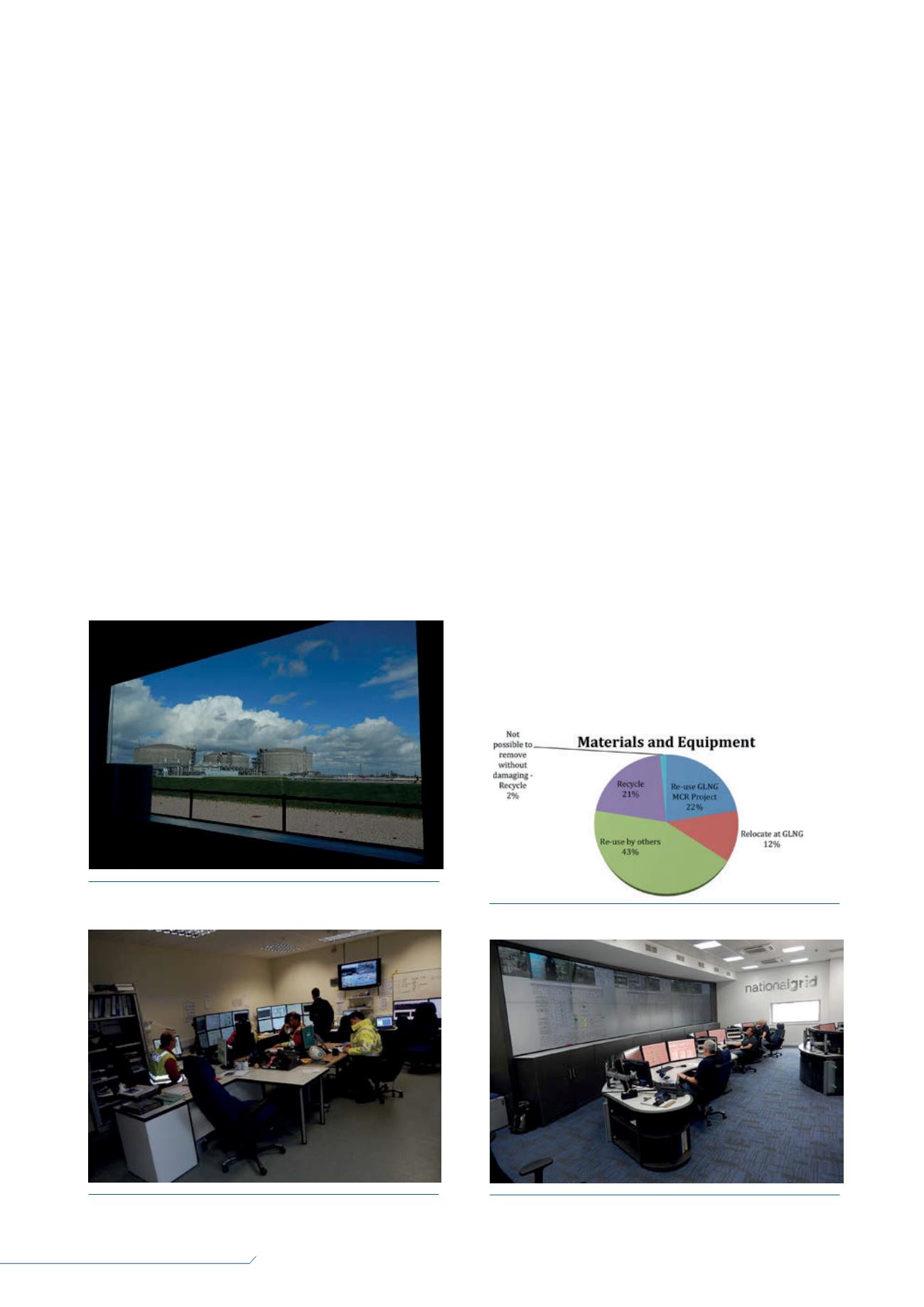

Figure 6.

Reuse statistics.

Figure 4.

View from the new window.

Figure 5.

Temporary control room.