76

LNG

INDUSTRY

APRIL

2016

It is important to avoid overcomplicating a once simple

system and ultimately overloading the very people that hold a

large stake in plant safety and efficiencies.

Need for change

Grain LNG had experienced significant growth in a relatively short

space of time. Within seven years, the terminal had gone from

a traditional peak shaving plant to a major import terminal, with

the largest above ground storage tanks in Europe, two jetties

with the ability to offload Q-Max vessels, as well as the ability to

deliver up to 20%of UK gas demand. Up to 1 million m

3

of LNG

can be stored on site, the largest in Europe.

The main control building was added as part of the second

expansion phase in 2008 and, whilst it could be argued that the

control roomwas functional, it certainly was not cutting edge and

did not reflect the investment made at the terminal (Figure 1).

More importantly, it did not help the shift team’s morale. The

limited space incorporated in the original design restricted the

ability for the terminal to expand further, as well as having a

multitude of human factor issues and poor operator control

graphics.

Structure and scope

The Grain LNG control systems team has significant experience

in working on operator graphical improvements and

alarm rationalisation, and has made some real headway in

understanding the operators’ needs. The team realised early on

that something needed to be done, so they focused on building a

case for refurbishment.

Options?

Upon investigation, it was clear that the project needed to

incorporate more than first expected. Not only should the control

room be considered, but the welfare facilities and building layout

all needed reviewing.

The systems team collated a variety of ideas, but focused on

what could be done to the existing building.

Turning the tables

This posed some questions. Should Grain LNG contract an

external body to carry out this project or use its in-house

expertise within the systems department?

An important question was whether the system should be

designed to fit the building, or whether the system should be the

focal point, and the building designed to accomodate it. It was

time to turn the tables and ensure that the building was designed

from the inside out, incorporating the operations and systems

team collaboratively designing the layout and interfaces.

Who is needed?

A team comprising of a systems project engineer, supported

by two main technicians, construction design manager (CDM)

liaison, procurement contact and key operations personnel was

established. The internal re-fit was carried out by an appointed

contractor, with all aspects of the control desks and video wall

completed by Grain LNG’s in-house systems team.

Raising the roof

Several human factors studies had been carried out over the

years and, through surveys, Grain LNG identified the following

key issues:

Poor lighting. No natural daylight.

Poor heating and cooling.

Cramped working environment.

Poor welfare facilities. Not enough lockers. No wet/dry room.

Standalone CCTV and handwritten plant status boards.

Display Screen Equipment (DSE) and ergonomic issues with

consoles.

No plant overview.

Compartmentalised view

of process.

Operating philosophy,

scope of responsibility

and standardised jetty

unloading screens.

‘Raising the roof’ relates

to the physical constraints of

the existing building. What

was possible; what are the

key deliverables; how far

could Grain LNG go?

Keeping within the original

footprint is a good example

of how there will always be

compromise, finding a

balance between cost and

functionality.

Figure 1.

The main control room.

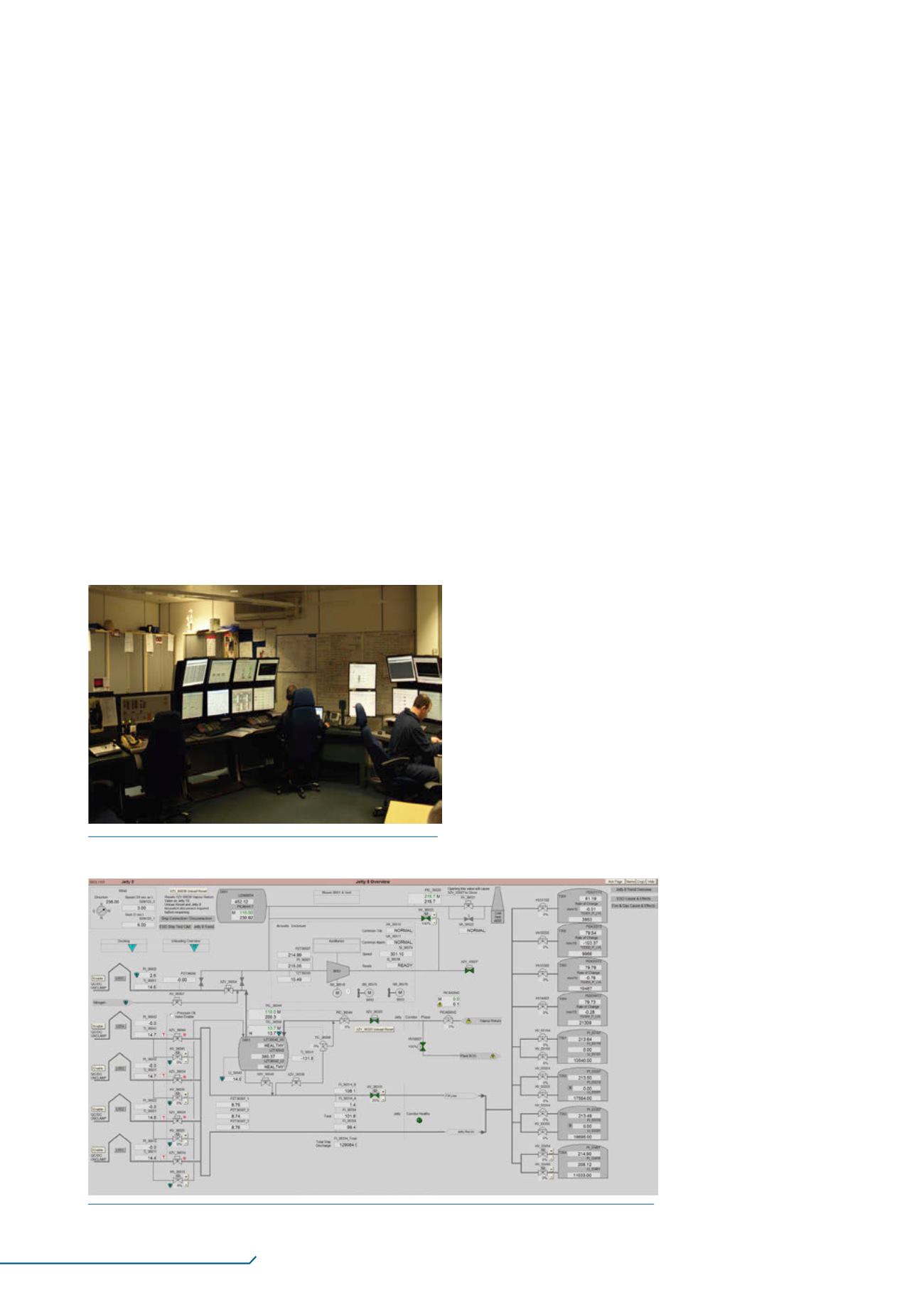

Figure 2.

Improved operator scope of responsibility and process review.