52

LNG

INDUSTRY

APRIL

2016

BOG in LNG terminals

LNG is stored as a boiling cryogenic fluid and does

not change as it is cooled by evaporation. BOG is

generated in LNG tanks and liquid-filled lines as a result

of heat influx from the environment. In order to avoid

environmental impact and loss of revenue to the owner’s

operations, BOG is generally not flared, but collected and

either recondensed or compressed for use as fuel gas or

grid send-out. Compression of the BOG is also required

prior to recondensation, as there is no cold energy source

available to condense the BOG at atmospheric pressure.

The amount of BOG that can be recondensed depends

on the amount of LNG send-out, because the LNG is

used as the cold energy source to condense the BOG. If

there is insufficient LNG send-out, the vapour must be

compressed to pipeline pressure.

During ship unloading, the quantity of BOG generated

in the tanks and piping increases significantly. This

additional vapour consists of: volume displaced in the

tanks by the incoming LNG; vapour resulting from the

release of energy input by the ship’s pumps; flash vapour

due to the pressure difference between the ship and the

storage tanks; and vaporisation from heat leakage

through the unloading arms and transfer lines. An increase

by a factor of 4 can be expected during unloading.

Technology considerations

for BOG compressors

In comparison to refinery applications, BOG compressors

do not run at constant operating conditions, because the

amount of BOG can differ significantly over time. The flow

is dependent on the amount of liquid in the tank, as well

as heat ingress. Furthermore, the flow increases heavily

during ship unloading. Therefore, it is required that BOG

compressors are equipped with provisions for capacity

control to be able to handle these variable boil-off

conditions.

Due to the low operating temperatures, lubrication of

compressor cylinders by means of mineral oils or

synthetic lubricants is not possible. Oil-free compressor

cylinders are mandatory for BOG compressors, due to the

oil behaviour at cryogenic temperatures. For instance, oil

could stick to the chillers and clog the piping system

during and after recondensation. Research has shown that

operating in the hydrocarbon mist (typically found in a

BOG compressor) can increase the wear by a factor of

400 – 500%. Therefore, rider rings, which carry the

weight of the piston and piston rod in horizontal

reciprocating compressors (Figure 1), and are always one

of the most vulnerable abrasion points in oil-free

compressors, may have to be replaced four to five times

more often than in conventional, non-lubricated

applications. Furthermore, the wear of the conventional

rider rings in oil-free compressors is unpredictable,

making a linear wear forecast virtually impossible in

scheduling maintenance stops by using a condition-based

maintenance approach. Failing to replace a worn down

Figure 1.

Howden Thomassen’s six-cylinder C-85.6

compressor.

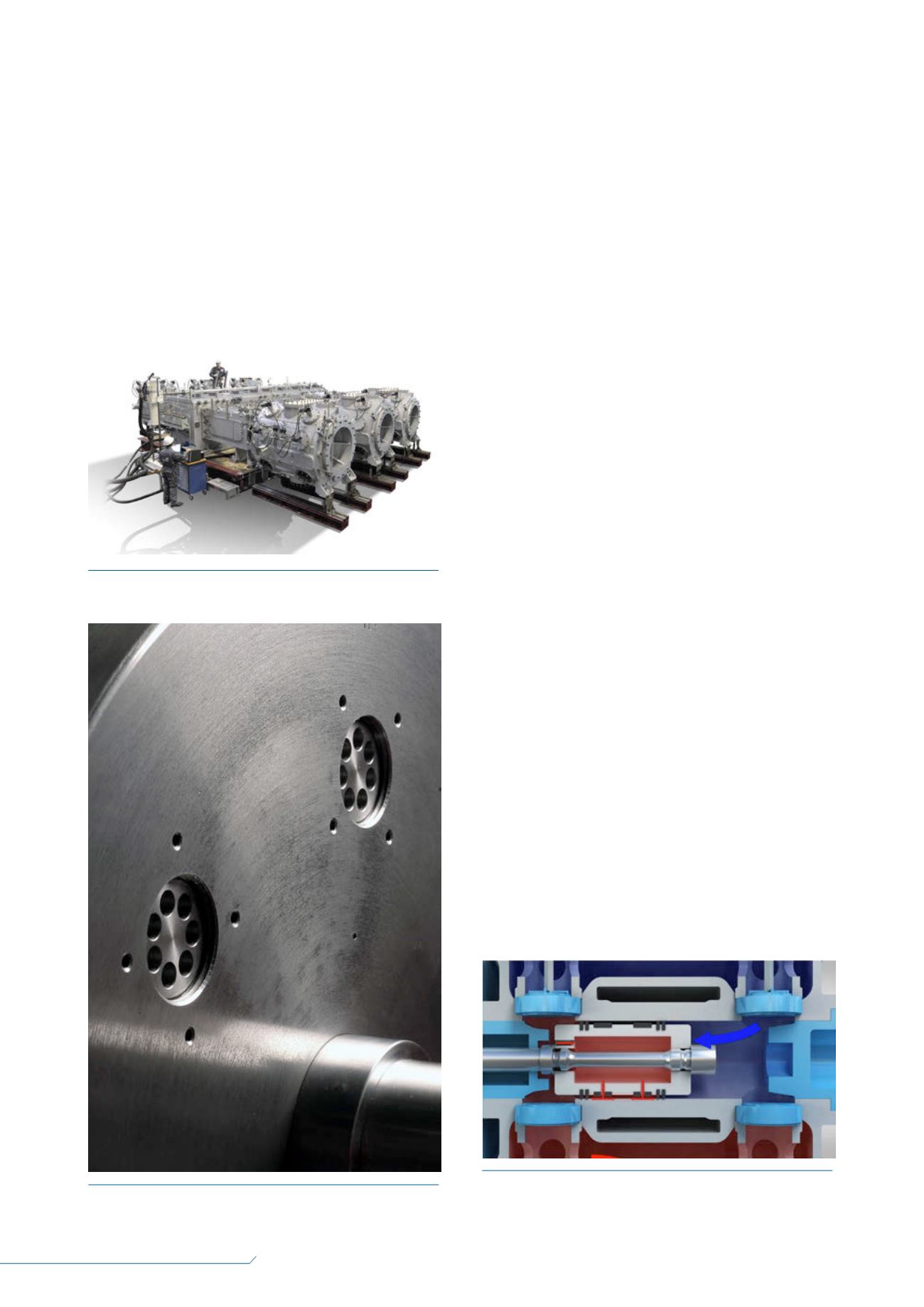

Figure 2.

Free Floating Piston (FFP

TM

) check valves.

Figure 3.

FFP operation principle for a double acting

compressor cylinder.