44

January 2020

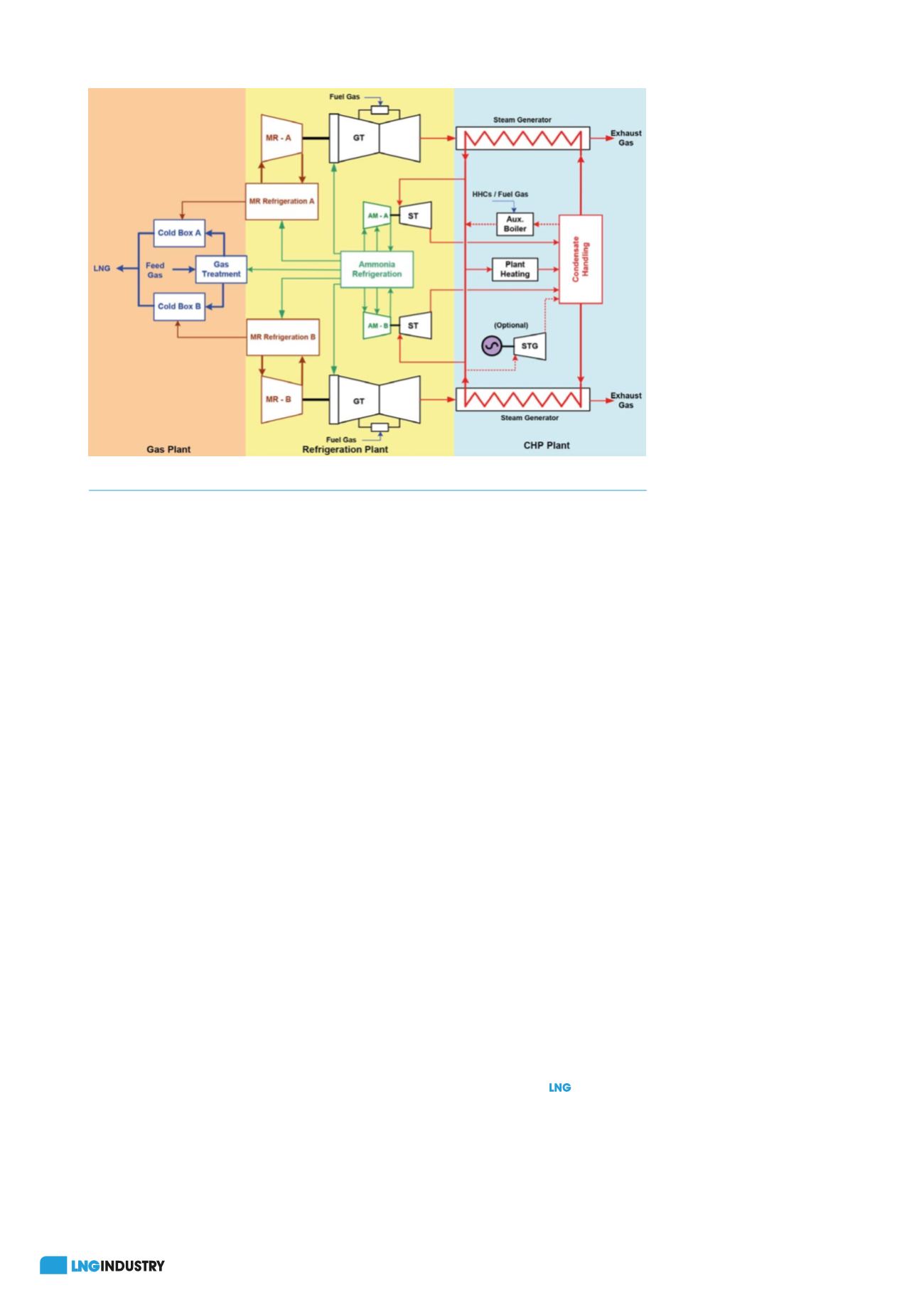

selection of smaller, compact, efficient gas turbines and

smaller steam turbines in the OSMR process is aimed at

developing simple, compact, modular mid scale LNG trains

with a nominal capacity of 2.0 million tpy. Plant availability

and turndown is increased by selecting a two-in-one train

design, where two identical liquefaction circuits with separate

mixed refrigeration loops powered by individual gas turbines

are used in each OSMR LNG train. A single pressure level is

utilised for the steam system to minimise complexity for the

2.0 million tpy nominal capacity LNG trains. LNG projects are

developed with multiple LNG trains capable of operating

independently while sharing a few plant utilities among the

trains, such as power, water, air and nitrogen. OSMR

liquefaction train based plants are developed in a similar vein,

with the closed steam and condensate handling systems

within each of the trains to maintain independent train

designs with better modularisation, construction and

operation. An auxiliary boiler is used primarily as a plant

waste gas consumption boiler and to assist with steam unit

startup and balancing. The primary waste gas in the plant is

high N

2

vapour rejected from the BOG recovery unit.

Typically, LNG plants are developed with their own

dedicated power plant rather than relying on the local grid. But

when reliable grid power is available, imported electrical power

is an efficient option to meet auxiliary plant power

requirements. Plant power demand in an LNG plant fluctuates

with ship loading operations causing an increase in plant

power demand. In remote locations where LNG plants are built

with no access to an electrical grid, plant power can be

generated within the site using a steam turbine generator in an

OSMR Plant, as shown in Figure 2. This would reduce the

amount of steam available to drive the ammonia refrigeration

compressors, hence reducing liquefaction capacity and train

production compared to a plant with imported grid power.

When multiple trains are in a plant, sufficient reliability is

provided by the multiple steam turbine generators. Plant power

demand increases during ship loading operations are met by

utilising more fuel in the aux boilers to produce more steam for

the power generators.

The use of an island

mode combined cycle power

plant to support an

all-electric LNG facility has

been proposed for certain

projects to improve thermal

efficiency compared to a

typical open cycle industrial

gas turbine driven LNG plant.

The use of electric drives in

large refrigeration

compressors adds more

complexity to an LNG plant,

requiring variable speed

drives for the large motors

along with the management

of startup and shutdown

dynamics of these motors.

Furthermore, the size of the

combined cycle power plant

including spares required to

meet an adequate level of

redundancy for an LNG facility

is generally much larger, therefore resulting in higher overall

project costs. The overall efficiency of the facility decreases

during operations since the power plant generally operating at

60 – 70% of its capacity, including installed spares. Therefore,

the optimum design will utilise a combined cycle refiguration

configuration, such as in the OSMR design.

Key takeaways

There is increased scrutiny on carbon emissions throughout

the natural gas supply chain, from upstream flaring to LNG

plants and LNG shipping. LNG plants consume a significant

amount of power and typically use open cycle gas turbines.

The power industry has moved from open cycle power plants

to combined cycle power plants, starting in the 1960s with

combined cycle considered best practice for the industry.

The LNG industry has used open cycle gas turbines for

driving refrigeration compressors over several decades with

minimal consideration for efficiency or carbonbemissions.

The use of combined cycle power for direct driving the

refrigeration compressors provides significant energy

efficiency improvement to an LNG plant, and can reduce

fuel consumption and carbon emissions by nominally

20

–

25% compared to traditional open cycle LNG plants.

The additional cost of equipment associated with the steam

system is offset by improved efficiency of the plant due to

fuel gas savings and the extra revenue from the additional

LNG produced in the plant. Furthermore, with reduced carbon

emissions, combined cycle refrigerant LNG plants, such as

the OSMR-based LNG plant, will have a smaller carbon

footprint,benabling it to be utilised in carbon constrained

jurisdictions and maintain social licence as a best available

technology.b

References

1.

‘Tangguh LNG – Energy EfficiencyMeasures through Life Cycle

Cost Analysis’,

Gastech

, (2005)

2. ‘GHG Emissions fromLNG Systems – AQatar Perspective’,

IPIECANatural Gas LCAWorkshop

, (2012)

3. BALLING, L. and BAUMGARTNER, R., ‘Forty Years of Combined

Cycle Power Plants’,

ASME Power Division

, (2002)

Figure 2.

The two-in-one OSMR® LNG process schematic.