46

January 2020

IMO Type C LNG fuel tanks

International Maritime Organization (IMO) Type C tanks

have until now been chosen due to a lack of alternative

LNG fuel tanks designed to withstand increased pressure

loads. Type C bi-lobe and even tri-lobe are offered for the

combination of high fuel volume and pressure tolerance for

ship types such as large containerships, cape size bulkers,

very large crude carriers (VLCCs) and car carriers.

Type C tanks need, per regulations, to be designed for a

pressure higher than 2 barg, depending on the tank size,

with larger sizes giving higher minimum design pressure. In

many cases, this does mean using more tank steel than

needed with regards to restrictions in weight optimisation.

Due to the rounded form of Type C tanks, there are further

restrictions in volume efficiency.

Prismatic LNG fuel tanks

The market has responded to the restrictions relating to

the IMO Type C tank by choosing very large, prismatically

formed LNG fuel tanks – the CMA CGM container

ships project in China being one high-profile example.

Furthermore, there are now different types of prismatic

fuel tanks hitting the drawing board for several other

large scale LNG fuel tank projects.

Prismatically formed LNG fuel tanks (i.e. membrane

types, IMO Type A and IMO Type B) have high volume

utilisation, but IMO regulations have restricted their pressure

capacity to an upper limit of 0.7 barg. For many projects, an

operation pressure limit of 0.7 barg is too low. One concern

is the holding time capability, which requires that the ship

be able to remain in an idle condition for 15 days without

venting gas. Other concerns relate to various operational

factors, such as how cold does the LNG need to be to avoid a

build-up of excessively high pressure in the tank after

bunkering? How quickly is it possible to bunker within the

limited pressure inside the tank? Movements inside the tank

in rough weather may cause a rapid increase in pressure;

how can this be handled within the 0.7 barg pressure

margin?

A solution to this problem is to fit boil-off handling

equipment, which can become expensive and power

demanding.

Pro and contra considerations for Type A, B, C and

membranes reveal that volume efficiency, steel weight and

tank pressure are strongly influencing the investment and

operation costs associated with using LNG as fuel.

Novelly designed LNG fuel tanks

LNG fuel tanks that are constructed according to available

ship volumes, and at the same time can tolerate a pressure

above 0.7 barg, were not accepted in the earlier revisions

of the IMO International Gas Carrier (IGC) Code. In the

latest revision, LNG tanks of novel design have finally been

introduced.

Novelly designed LNG tanks create the opportunity to

combine prismatically formed tanks and pressure build-up

possibilities, with the freedom to choose tank design

pressure. A thorough design and safety philosophy is a

prerequisite for getting authority and class approval for

novel designs. This design method is called ‘limit state

design’.

Briefly described, the reliability and safety of a novelly

design tank, under increased pressure, shall be equivalent or

better than the prescriptive tank types defined in the

IGC Code.

2 barg pressure prismatic LNG

fuel tank

LNT Marine specialises in prismatically shaped marine

LNG tanks and LNG tank insulation. The company’s novelly

designed LNG tank, which is called the LNT Fuel-Box, has

been developed in close cooperation with the classification

society ABS. As a result of this cooperation, ABS issued an

approval in principle (AiP) for the LNT Fuel-Box in 2019.

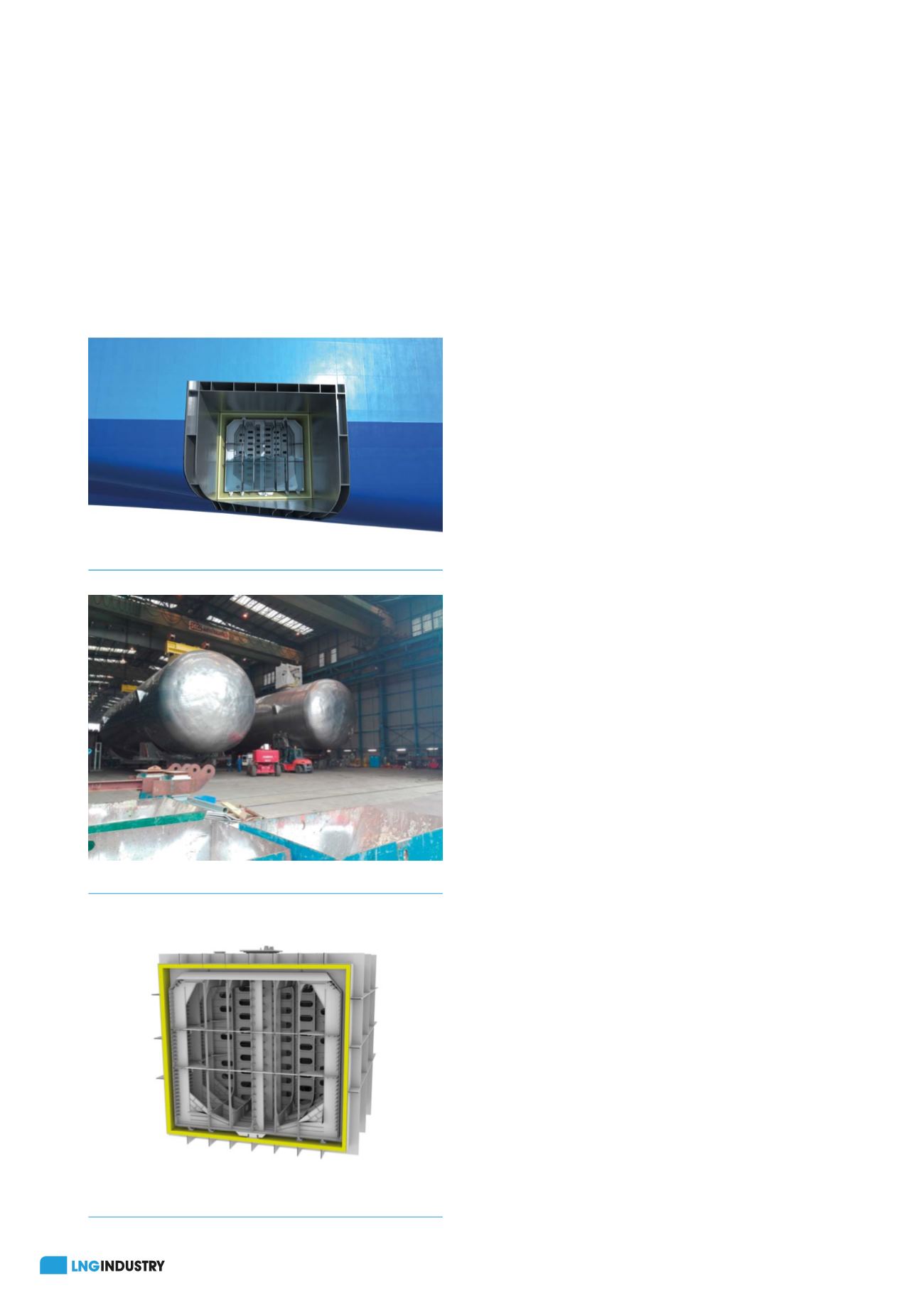

Figure 1.

Prismatically formed LNG fuel tank.

Figure 2.

Foam insulated IMO Type C fuel tanks.

Figure 3.

Arrangement of an LNT Fuel-Box.