42

January 2020

efficient best available technologies in reducing its carbon

footprint throughout the natural gas value chain, including LNG

production.

LNG plants have traditionally been developed as integrated

projects by stranded natural gas asset owners controlling the

entire value chain. Focus was placed on reducing capital costs

due to its high cost outlay and long payback periods at these

remote sites. These projects often overlooked operating cost

savings, as typically feed gas cost was minimal for an integrated

project developer. Further, there were no strict regulations in

place to reduce carbon emissions in jurisdictions where LNG

projects were developed. Plant improvements were focused

around equipment design enhancements, such as improving gas

turbine metallurgy to withstand higher exhaust temperatures,

optimising compressor driver arrangement and increasing heat

transfer area per unit volume in heat exchangers. Although the

benefits of waste heat recovery and combined cycle power were

well understood, the vast majority of LNG plants continued to be

built with open cycle industrial gas turbines as an inefficient but

capital cost-friendly approach, with little or no consideration paid

to CO

2

emissions and operational efficiencies.

The growth of LNG projects with third-party pipeline feed

gas, coupled with lower LNG prices and an increased awareness

of CO

2

emissions, have caused project owners to focus more on

plant efficiency improvements and embrace the use of

innovative technology to improve project lifecycle economics.

This article looks at how purposefully designed mid scale LNG

trains with combined cycle heat integration can increase LNG

plant efficiency and reduce carbon emissions while remaining

highly cost-competitive.

LNG plant energy efficiency

LNG plants convert feed gas into a chilled liquid product

after removing the contaminants from the natural gas. LNG

plants use part of the feed gas as fuel to produce the required

energy to provide refrigeration, gas treatment, plant heating,

boil-off gas (BOG) handling, ship loading and other utilities.

The plant efficiency is therefore calculated by the ratio of the

heating value of product to the heating value of the feed gas,

which typically ranges from 88% to 92% for LNG export plants

located close to the equator.

LNG liquefaction efficiency is primarily influenced by two

factors: heat exchange efficiency, and the efficiency of

turbomachinery. Heat exchange efficiency depends on the

refrigerant selection, liquefaction process configuration,

exchanger type and temperature approach. Turbomachinery

efficiency depends on the selection of gas turbines and

compressor string arrangement. A considerable amount of

optimisation has been undertaken in traditional export scale

liquefaction processes to maximise the heat exchange

efficiency by optimising the cooling enthalpy curves. Similarly,

the move to aeroderivative gas turbines over industrial frame

gas turbines coupled with refinement of refrigeration

compressors have seen gradual efficiency improvements in

turbomachinery over the years of a few percentage points.

LNG plants can also utilise heat integration and boil-off

recovery to reduce fuel consumption and improve energy

efficiency. Large scale LNG plants have often implemented

limited sensible heat recovery systems from the compressor

drive gas turbines exhausts. The most common method is to

use a heat transfer medium, hot oil or water, to recover sensible

heat from the gas turbine exhausts to be utilised in the acid

gas removal unit, molecular sieve dryer regeneration, and in

fractionation units. The use of heat recovery steam generators

(HRSGs) to recover waste heat from the gas turbine exhausts

has been implemented in a few LNG plants, such as in

Tangguh LNG,

1

Qatar LNG Trains in Ras Laffan

2

and recently in

Cove Point LNG. This article looks at heat recovery arrangement

where waste heat from gas turbine driving the mixed

refrigeration loop is utilised to drive a steam turbine that

powers the precooling refrigeration circuit, thus forming a

combined cycle refrigeration system. A significant increase in

LNG plant efficiency can be achieved when such a combined

cycle refrigeration arrangement is utilised in LNG plants.

Combined cycle power plants

Gas turbine power plants have adopted combined cycle power

generation since the 1960s to increase efficiency. Initially,

HRSG units provided steam for co-generation applications,

since the gas turbine temperature level was still relatively

low. In the late 1960s, the gas turbine unit sizes became

large enough to start building combined cycle power plants

with HRSGs supplying the main steam for a bottoming steam

turbine cycle. Cogeneration is also referred as combined heat

and power, which provides electric power and process steam

with higher fuel efficiency. The introduction of Public Utilities

Regulatory Policy (PURPA) in 1978 had promoted the use of

cogeneration plants in the US.

3

With advancing gas turbine

technology, combined cycle power plants reached net efficiency

levels closer to 60%, meeting US Department of Energy (DOE)

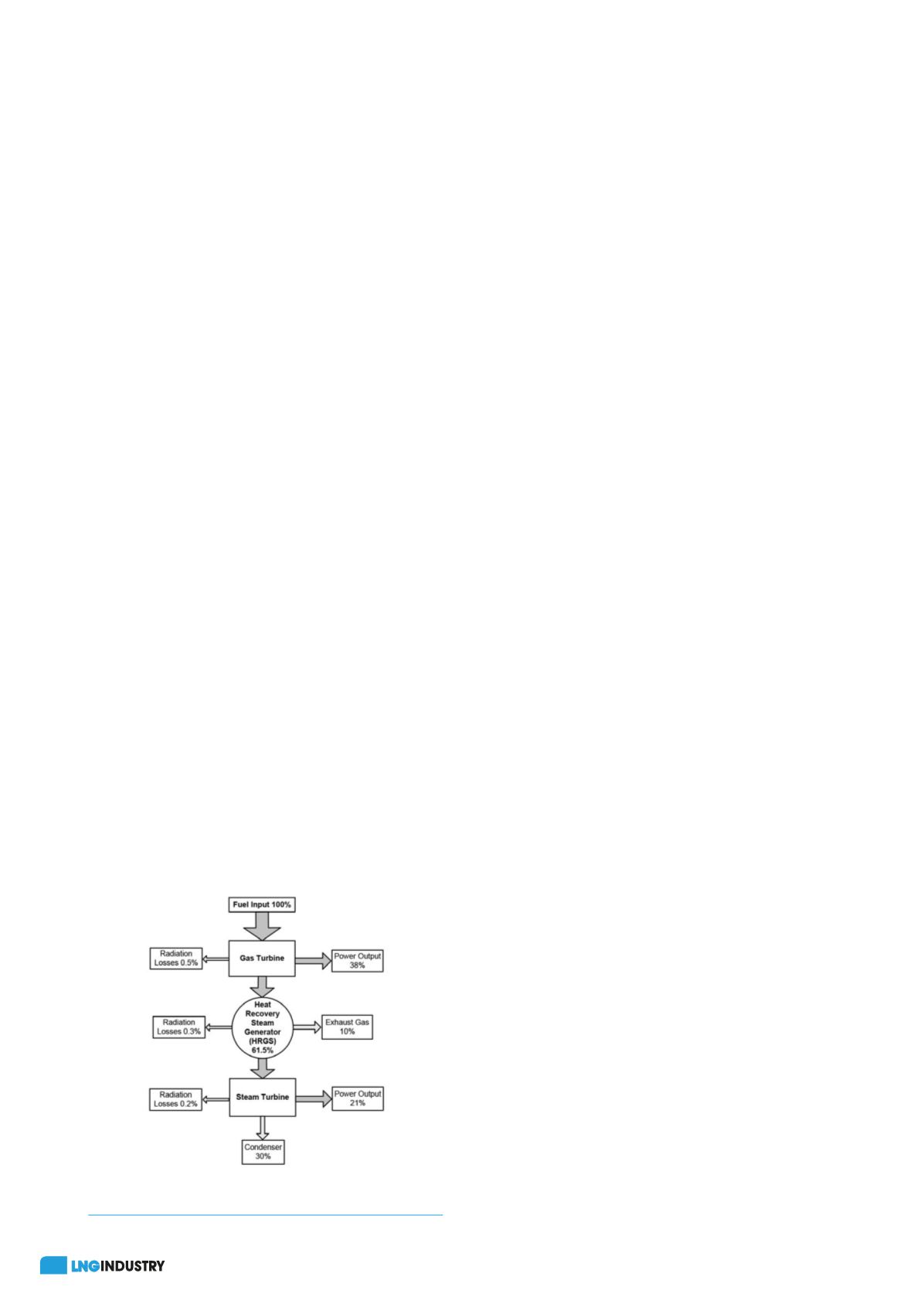

efficiency targets in the 1990s. An energy distribution schematic

of a typical combined cycle power plant is provided in Figure 1.

Combined heat and power plant

Heat integration and combined heat and power forms the

central part of the patented OSMR® LNG process. Waste heat

from the mixed refrigerant compressor gas turbine exhaust is

utilised in steam generators to produce high pressure steam,

and then used to drive the precooling refrigerant compressors

and meet plant heating requirements. A process schematic is

shown in Figure 2.

Combined cycle configuration in an LNG plant should

avoid complex steam systems to ensure capital costs

associated with steam systems remain minimal and enable

plant operators to focus on LNG production operations. The

Figure 1.

Energy distribution in a combined cycle power

plant.