38

January 2020

focusing on the key elements within the chain. This article

specifically focuses on the LNG liquefaction facility. GHG

mitigation measures are compared and discussed by

considering a realistic LNG facility case study, identifying the

steps required to reduce GHG emissions. This approach

demonstrates how a project could be configured to meet

stringent GHG emissions targets.

GHG emission sources

To effectively target the right carbon reduction measures, the

emitters must first be identified and then assessed to what

degree they impact the overall emissions.

Carbon dioxide (CO

2

) in the feed gas is one source. For

high CO

2

field developments, this has a significant impact on

GHG emissions. For all liquefaction processes, the CO

2

in

feed gas must be removed to a strict specification to prevent

cryogenic freezing, and is typically removed with amine

before being released into the atmosphere. Rather than

releasing CO

2

into the atmosphere, some facilities with high

CO

2

content reinject it back into a reservoir. This is often

seen as the initial step in reducing emissions from these

developments. This is the case for both Hammerfest LNG and

more recently Gorgon LNG.

A second, and major, CO

2

emitter is the liquefaction

process, as it requires huge amounts of energy to drive the

refrigerant compressors. This energy typically derives from

burning fuel gas in gas turbines resulting in high CO

2

emissions. Some facilities use electric motors to drive the

compressors instead of gas turbines, with the electric power

being delivered from a low CO

2

emissions source.

Hammerfest LNG was the first baseload LNG plant with

electric drives, but more recently Freeport LNG also adopted

this approach. Future projects, such as Kitimat LNG, are also

exploring an e-drive solution with power imported from

hydroelectric sources.

Auxiliary power generation is another CO

2

emitter for

consideration. The majority of facilities generate this power

through the use of gas turbines. However, some projects,

such as Canada LNG, are considering importing auxiliary

power from a renewable power source as a means of

reducing emissions.

GHG emissions reduction

measures

These key CO

2

emitters are where emission reducing

measures need to be applied. Existing LNG plants have

varying GHG emissions for these sources and some facilities

can be as high as 0.46 t of CO

2

equivalent per tonne of

LNG (tCO

2

e/tLNG). By focusing on a case study, it can be

observed how the GHG emissions are affected by various

GHG emission reduction measures. For this evaluation, a

tight GHG emissions limit of 0.16 tCO

2

e/tLNG is targeted, in

line with the regulations of British Columbia, Canada. The

measures for consideration are grouped into four categories:

electrification; efficiency enhancements; technology

advancements; and carbon capture.

The case study

The case study consists of an onshore liquefaction facility

operating with conditions similar to those observed in

Canada – a region of the world where there is considerable

LNG activity with numerous projects expected to reach a

final investment decision (FID).

The key parameters include the following:

z

Feed gas composition (CO

2

, nitrogen, hydrogen sulfide

and methane being <0.7, 0.7, 0.5, 90 mol %, respectively,

with the balance being heavier hydrocarbons).

z

An air-cooled facility with 10°C ambient air

temperature.

z

60 barg liquefaction feed gas pressure.

z

Dual mixed refrigerant (DMR) liquefaction technology

consisting of refrigerant compressors driven by

aeroderivatives.

z

Auxiliary power is generated within battery limits by gas

turbine generators operating on fuel gas.

When considering liquefaction technology selection,

many other important factors and criteria are considered in

addition to efficiency, so the benefits of the various

liquefaction technologies and their licensors should be

reviewed in conjunction with any impact on GHG emissions.

This does not form part of this evaluation.

Figure 1.

Floating wind turbine.

Figure 2.

Just Catch™ carbon capture technology.

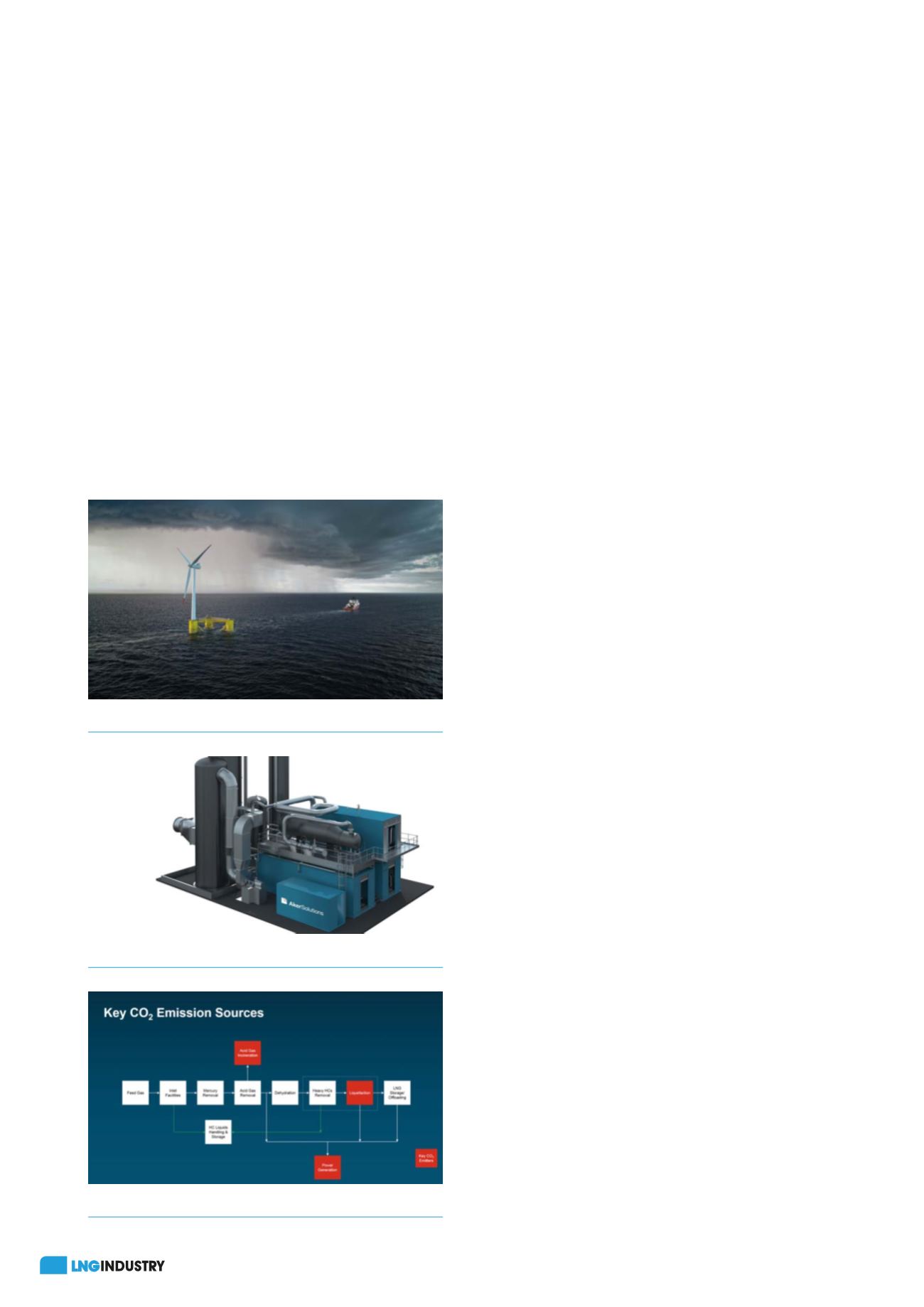

Figure 3.

CO

2

emission sources from LNG trains.