34

January 2020

engineering based on a vessel designed to carry LNG tanker

trucks with an onboard loading module to fill the trucks through

ship-to-ship (STS) transfer.

The LNGTC, with the loading module and the tanker trucks,

in combination with auxiliary infrastructures on the ground, is a

flexible, scalable solution that will meet the present and future

small and medium scale LNG market demands, allowing

end-users access to an economical, safe and environmentally

friendly energy source.

LNGTC

Schematically, the solution requires an LNG supply entity, such

as an LNG carrier, a floating storage unit (FSU), a floating storage

and regasification unit (FSRU), or an LNG export terminal, and

the patented LNGTC. The LNGTC has a deck area enabled to

arrange the tanker trucks, each in its corresponding loading

bay. It is also equipped with a connection module to the LNG

supply entity, an LNG loading module for the tanker trucks, a

distribution module that links the LNGTC connection module to

the LNG supply entity and to the loading module for the tanker

trucks, and access and exit ramps.

The connection module consists of the following:

z

Cargo hoses between the LNGTC and the LNG supply entity,

which are used for the transfer of LNG, nitrogen and gases

from the vaporisation of the LNG.

z

Boil-off gas (BOG) return line. This BOG can be also used for

the feeding of the engines or turbines of the LNGTC.

z

Nitrogen connection, which fills the tanks, pipes and hoses

with inert gas.

z

Instrumentation and control equipment to monitor and

control the transferred LNG, nitrogen and gas discharge.

LNG logistics and supply chain

The LNGTC sails between an LNG carrier position and the

Ro-Ro dock at the port, where it facilitates the exit and

subsequent return of tanker trucks for LNG distribution among

end customers. With this system, neither gas storage tanks

nor distribution facilities in the port are needed, since the

tanker trucks are autonomous to move inland to the customer

facilities.

The end customer may be one of the following: an electric

power generation plant that uses gas as a means of producing

energy, either through turbines or combustion engines; a

regasification and channeled distribution plant of gas to small

end consumers; an intensive gas industry; or even a small

consumer, such as a hotel complex or a hospital.

The LNG supply entity supplies the LNG to the LNGTC to

refill the tanks, performing this operation at sea or at an LNG

terminal under suitable metoceanic conditions.

Once this operation is finished, the LNGTC sails to the

nearest port and dismebarks the LNG tankers trucks, which will

drive by road to the final consumer. Once unloaded, the tanker

trucks drive back to the port, where they return to embark on the

LNGTC, waiting to be filled again when the LNGTC sails back to

the LNG supply entity.

Figures 1, 2 and 3 show the sequence of operations that

would be performed to supply the daily demand.

Certifications and patents

One of the highlights of the LNGonWheels project was

obtaining the ‘approval in principle’ (AiP) certification from the

American Bureau of Shipping (ABS), following its procedure of

new concepts evaluation.

Previously, a hazard identification (Hazid) study was chaired

and scribed by ABS.

In parallel, the patent application processes were started

and two Spanish patents have been granted in recognition of

the innovative nature of the LNGonWheels solution:

P 201730936 ‘Carrier for Carrying LNG Tanker Trucks’ and

P 201730935 ‘Maritime System for the Transport and

Distribution of LNG’.

The target was to patent a solution which significantly

reduced the total cost of investment associated with the

installation of new natural gas import infrastructures, providing a

cost-effective and environmentally friendly gas solution to small

and medium scale customers located in marine areas.

Further studies

With the support of SiPort 21, Naturgy has developed a

compatibility analysis of the LNG supply entity with the LNGTC to

carry out STS LNG transfers in different operating scenarios.

A dynamic analysis of the behaviour of the moored ships is

being performed (LNG carrier and LNGTC side-by-side). The scope

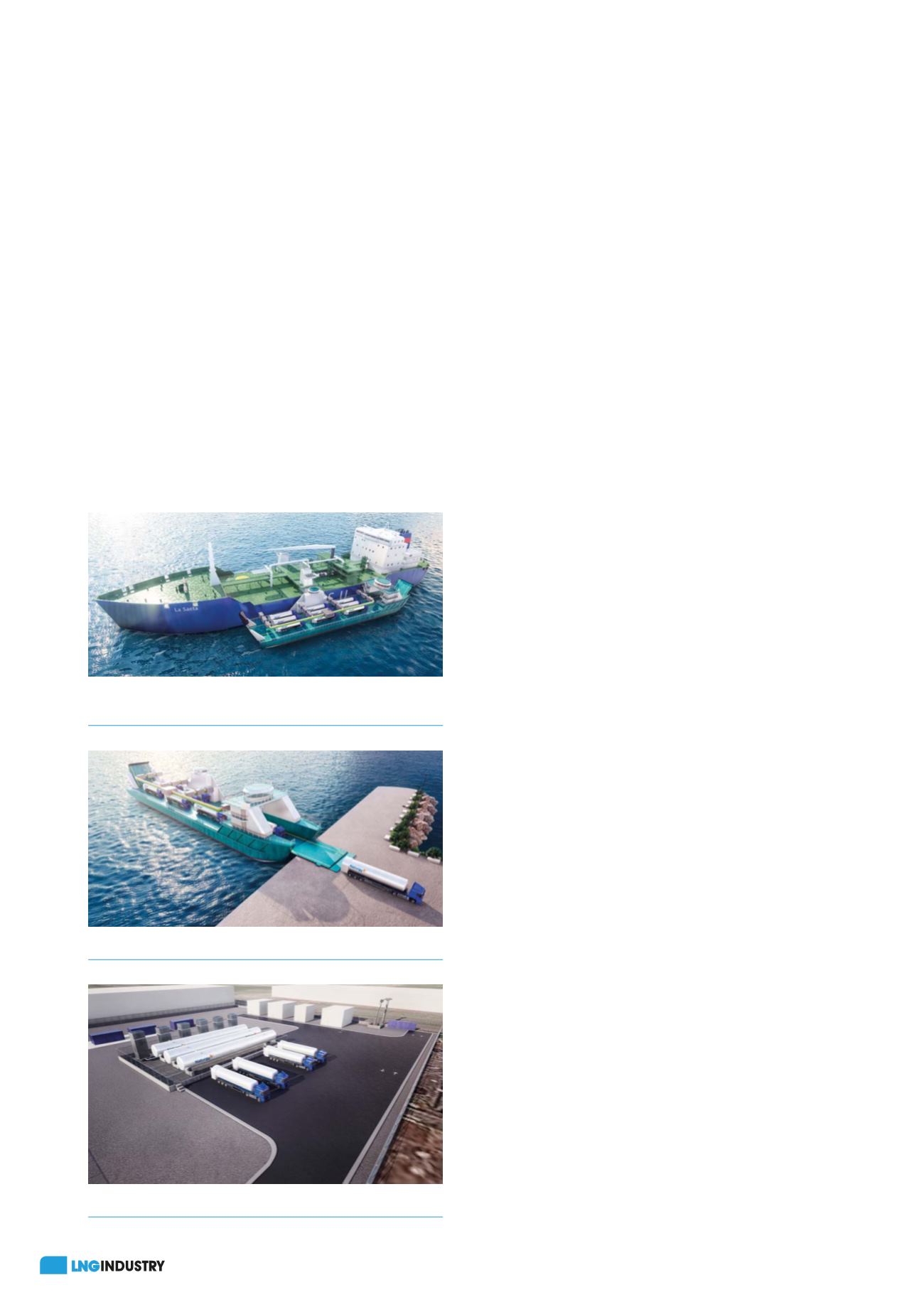

Figure 2.

LNG tanker trucks disembarking from the LNGTC.

Figure 1.

Feeding process of LNG tanker trucks on top of

the LNG tanker truck carrier (LNGTC).

Figure 3.

LNG satellite plant operations with tanker trucks.