54

LNG

INDUSTRY

SEPTEMBER

2016

the process and awareness of the conditions presented by the

system.

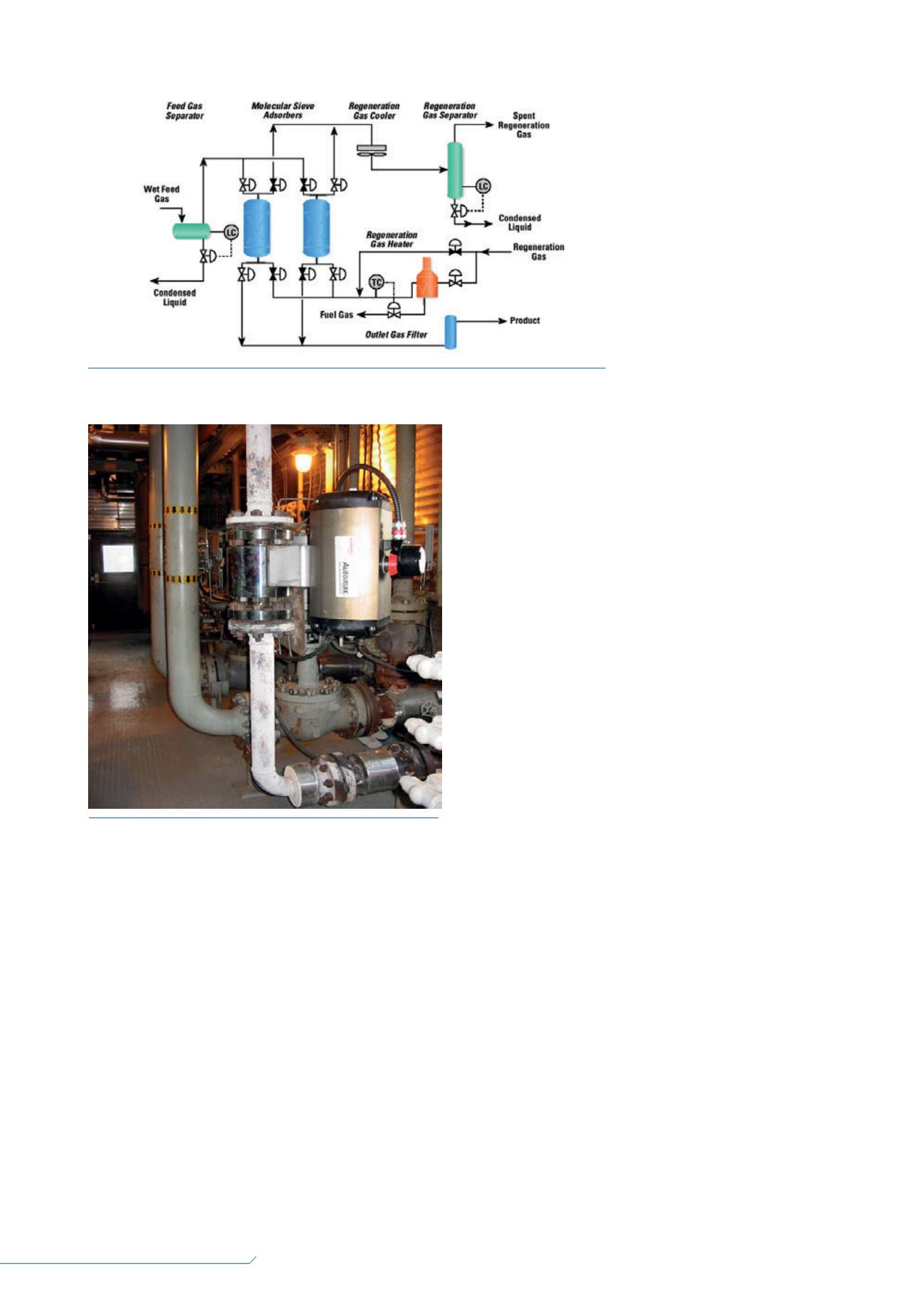

During gas treating, removingmoisture from the gas is an

important step to protect equipment and components of the

piping system. With H

2

S and CO

2

present in natural gas feeds to

the LNG facility, there is potential to generate sulfuric acid and

carbonic acid, which increases corrosion rates of several materials

typically used in piping systems. Dehydration (also known or

referenced as molecular sieves) of the natural gas becomes an

important step in protecting piping systems and plant safety

(Figure 1). This process typically will have at least two towers, but

there can bemultiple towers with absorptionmedia to collect the

H

2

O. These towers typically consist of beds holding desiccant

beads. As the absorptionmedia becomes saturated, it must be

regenerated by reverse flowing with high temperaturemedia to

drive off and collect the process water for disposal. In two-tower

systems, one unit will be in absorption phase and the second will

be in regeneration or stand-by phase. As a result, switching valves

are required to isolate between the

towers for efficient operation of each

unit. These valves need to handle

high cycles, high temperature, high

pressure and varying process media

with abrasives and corrosives. The

abrasives and corrosives present wear

potential to valve sealing and

operating components, which

impacts long-termperformance and

safety.

Review the valve

and the process

CGIS began working with a large

producer and operator of a molecular

sieve system, in which switching

valves were causing process

inefficiencies. The challenges faced were isolation and cycling

failures occurring at random intervals, which required repair or

replacement on average every 18months. Through review of the

valves and process, it was found that the seats and ball were

being damaged by abrasives from the natural gas and desiccant

beads in the towers. In reviewwith operations teammembers, the

company discovered that valves seized or stuck during operation,

caused by design andmaterial build-up in key areas of the valve,

which would require immediate attention at all times of the day.

The process conditions present were as follows:

1100 psig (76 barg) plant operating pressure.

40 – 285°C plant operating temperature.

Sour natural gas consisting of the following:

20%H

2

S average (ranging from 17% to 35%).

10 – 12%CO

2

.

8 – 10%H

2

O.

55 000 – 65 000 ppm chlorides.

Asphaltines, sand, sulfides, mercaptans, light hydrocarbons.

Desiccant dust.

As a result of the review, CGIS realised that the sealing and

operating components of the valve would have to provide high

wear resistance to the dynamic conditions of temperature,

pressure, and both abrasive and corrosivemedia.

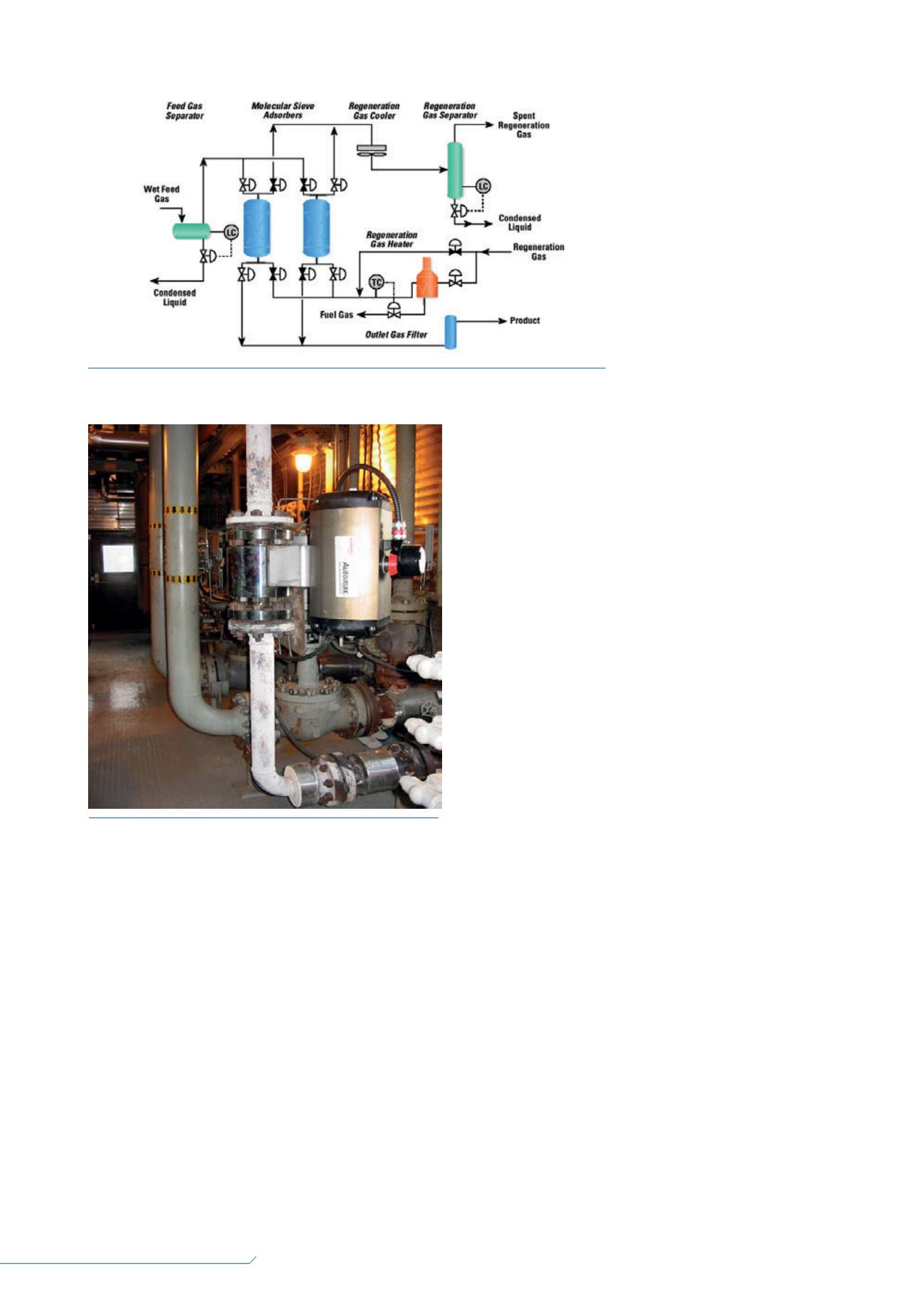

The solution provided was ValvTechnologies’ V Series

quarter-turnmetal seated ball valve (Figure 2), which can handle

the challenges and dynamic conditions of this particular

application.

Ball valves are generally categorised as either fixed or floating

based on the position or movement of the ball. Trunnion-mounted

ball valves would be a fixed ball valve design where the seats are

pushed towards the ball via springs and process pressure from

behind seat rings. The ball is held in position via a lower and upper

stem connected to the ball. Pressure-assisted or floating ball valve

designs use process pressure tomove the ball into and hold it

against the downstream seat. In these designs, there are two

potential leak paths:

Between the ball and seat.

Behind the loose seats mounted in the body.

In this particular application, rising stem ball valves were in

service and the producer found repairs and replacement to be a

Figure 1.

Open cycle molecular sieve dehydration system.

Figure 2.

ValvTechnologies’ 3 in. class 900 V Series valve for

molecular sieve regeneration switching installed in July 2003.