53

S

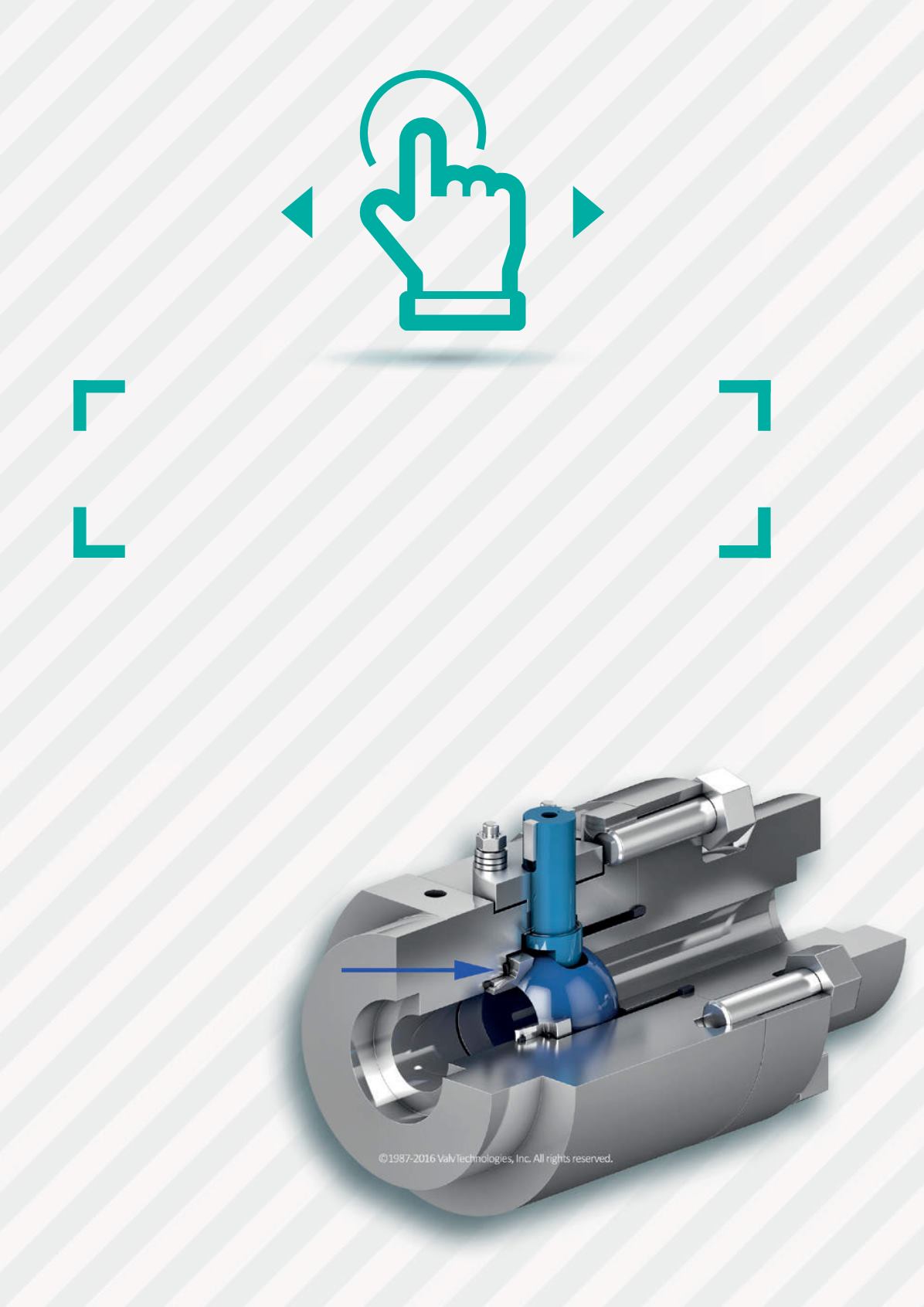

hutdowns for valvemaintenance or replacement are costly to plant capacity and, ultimately,

revenue. As end users strive tomaximise their operating performance and efficiency,

valvemanufacturers are forced to evolve their valve designs tomeet their customers’

expectations and demands. Implementing new designs andmaterials into the valve design is

one way to keep up with the evolving requirements. Another approach is to concentrate

on using the best valve for the application, rather than simply looking at the design and

material specifications. It is crucial that the application and process conditions are

considered when determining which product is selected. In this article, CGISwill

look at an application solution, along with valve design, to address challenges

faced in process industries.

LNG plants typically consist of liquefaction and gas treating areas to

condition the gas to be converted into liquid form. The process and

applications within these facilities are demanding for valves.

Proper review of the operating conditions of the valve should

be completed before a selection is made. The following

application is an example of looking at many aspects of

Kevin Niebergall, CGIS,

Canada,

explains the

importance of selecting the

right Severe Service Valve

(SSV) for LNG applications.

SHREWD

SELECTION