46

LNG

INDUSTRY

SEPTEMBER

2016

resources or associated gas that could not be tied-back to a

major LNG plant onshore or otherwise valorised. It has also

been seen as an opportunity to reduce time for gas to

market in many places, while maintaining a competitive

advantage for small to medium scale liquefaction plants.

However, it took some time for the concepts and

technologies to mature before the installation of the first

permanent offshore regasification terminal near Rovigo,

Italy (a gravity-based structure), in 2009. In the same year,

the first floating storage regasification units (FSRUs) berthed

at quayside in sheltered areas in Brazil. At the end of 2013,

OLT Offshore LNG Toscana’s floating regasification terminal,

FSRU Toscana

, was permanently moored off the Italian

coast, between Livorno and Pisa. Now, the first floating

liquefaction units are under construction and will probably

commence LNG exports in 2017. Despite a challenging oil

and gas market with low prices offshore, LNG projects and

technologies are continuing to attract a great deal of

attention from both major and smaller operators. This article

outlines the various types of offshore LNG unit.

FSRUs

The number of operating FSRUs has been continuously

increasing over the past few years, with a dozen now

operating throughout the world. A relatively simple process

ensured that these regasification facilities were the first

LNG plants to be installed on a floating facility. A major

reason for the success of FSRUs is the flexibility offered

by a floating facility in a commercial leasing scheme,

e.g. regasification vessels can be used on a seasonal basis.

However, even on a permanent basis, the FSRU concept

remains an attractive alternative to traditional land-based

onshore regasification terminals. Indeed, few modifications

are needed to convert a standard LNG carrier (be it for

a conversion or on a purpose-built hull) to an FSRU. For

instance, the regasification module can be compact, and

the transfer systems can be moved onto a jetty if the FSRU

is berthed at quayside, etc. Moss Maritime, a Saipem

subsidiary and developer of the spherical tank containment

systems for LNG carriers, performs these conversion studies

using in-house technologies. Several of the currently

operating FSRUs are a result of Moss design.

Even a complete, truly offshore FSRU, with mooring and

LNG offloading functions included, can be competitive

against onshore terminals and provide an answer to the

challenge of installing regasification facilities in

industrialised coastal areas where available space is often

limited, authorisations can be difficult to obtain, and local

populations can be hostile to the installation of such plants

in their communities. An example of a truly offshore FSRU is

the

FSRU Toscana

(OLT) built by Saipem. The project

consisted of converting an LNG carrier into an FSRU through

the addition of a module for regasification, marine loading

arms for offshore LNG transfer, a turret for the permanent

mooring of the vessel, and thrusters to assist offloading

operations.

Offshore liquefaction

The development of offshore FLNG facilities has been

slower than the development of FSRUs due to the more

challenging technological hurdles to be overcome and a

higher perceived risk due to this additional complexity.

However, the first facilities are now in the final stage of

construction and floating liquefaction will soon be an

operating reality.

The incentives to move a liquefaction export terminal

offshore are different from those of a regasification terminal.

Indeed, the purpose here is usually to produce remote or

isolated offshore gas fields that are either too small to

justify the investment in an onshore liquefaction plant, or are

too far from existing plants to make a tie-back to such a

plant viable. However, an offshore floating liquefaction

plant can also prove to be more cost-effective and faster to

build than an onshore plant, especially when no

infrastructure exists onshore, since a floating LNG (FLNG)

unit can be fully built in shipyards, under cost-effective

working conditions. However, the large, but still limited,

area available on the deck of an FLNG unit (designs usually

consider hull lengths up to 500 m) limits the production

capacity that can be achieved on a single floater, typically

approximately 6 – 7 million tpy of LNG for the most

favourable cases, i.e. for lean gases that do not require

significant NGL and LPG extraction and production in

particular.

Saipem has been developing and improving

technologies that help make FLNG a competitive and

enabling solution for producing offshore gas fields. Some of

these developments relate to the core of the process design

of the plant, i.e. the liquefaction cycle. For example,

optimisations have been made to open-art nitrogen

liquefaction cycles, which are robust and easy to operate at

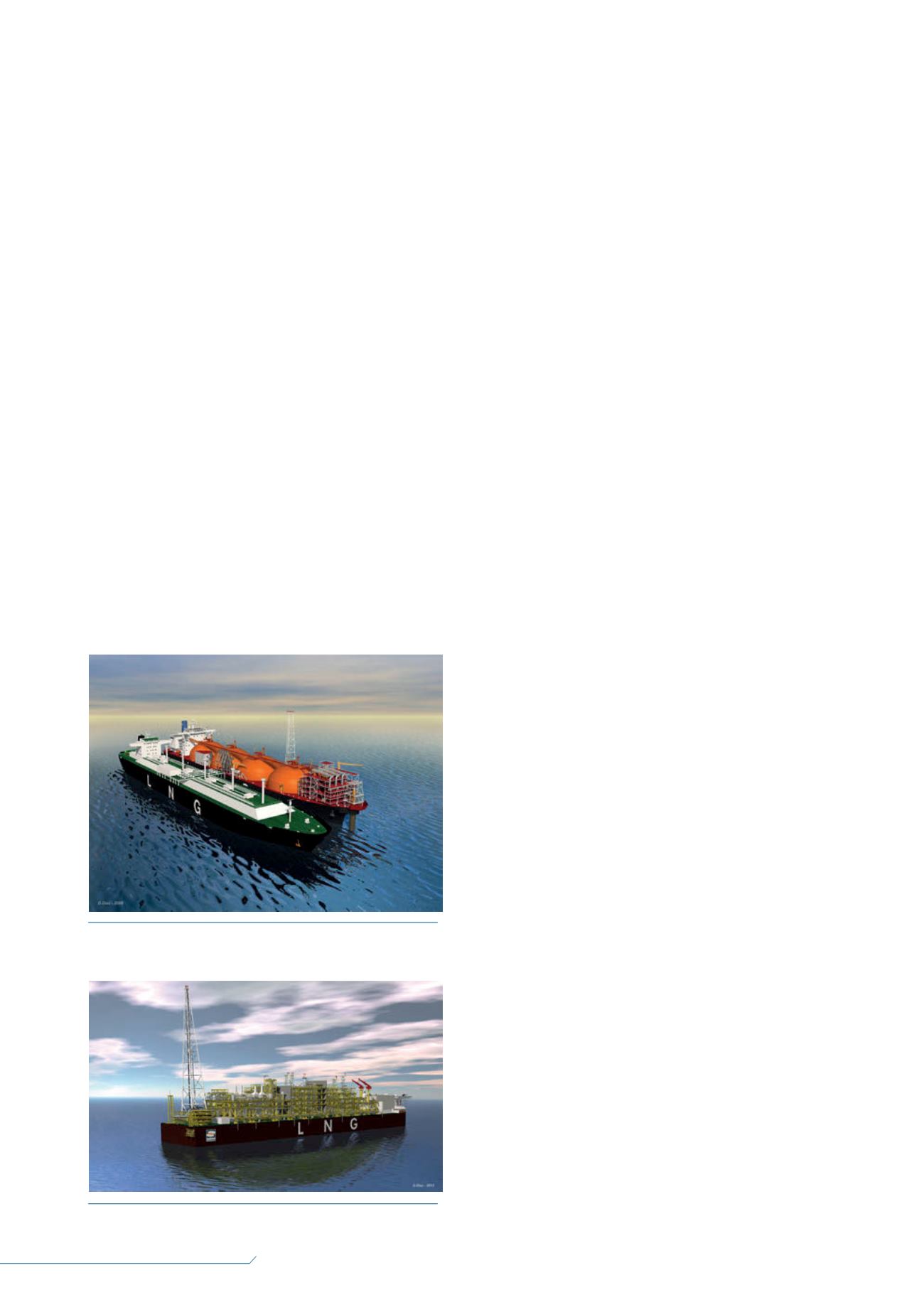

Figure 1.

Side-by-side offloading on a converted floating

storage regasification unit (FSRU).

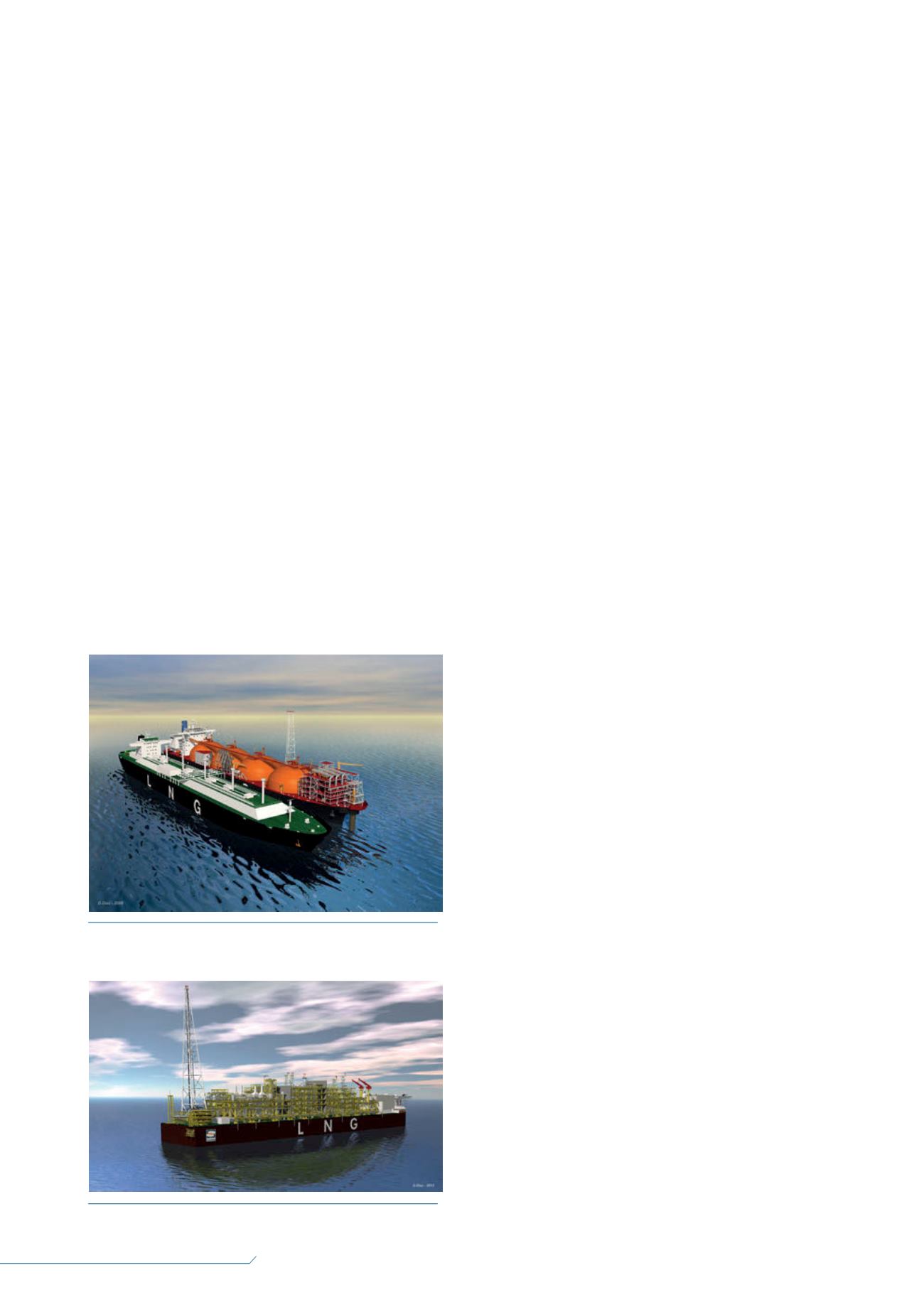

Figure 2.

A typical 3 million tpy floating LNG (FLNG) unit.