48

LNG

INDUSTRY

SEPTEMBER

2016

the expense of a lower efficiency compared with single

mixed refrigerant (SMR) and dual mixed refrigerant (DMR)

cycles, to help maximise their efficiency. Such cycles are

particularly relevant for small to medium scale FLNG units,

and may be implemented either on newbuilds or converted

LNG carriers. Here again, Moss Maritime is involved in

projects aiming at converting Moss LNG carriers into small

scale FLNG units thanks to the addition of sponsons on the

sides of the vessel to accommodate the topsides modules.

Another area for technology development is safety in

FLNG design. In this regard, one specific aspect of FLNG

operations is the large inventory of LNG and cryogenic fluids

required, which may pose a threat to the carbon steel

structures composing the hull and topsides modules. The

prevention and containment of cryogenic leaks is an area that

is seeing a great deal of work. Saipem has been developing

tools to improve the prediction of the impact of such leaks in

modules and on deck, so that leak protection systems can be

designed more efficiently.

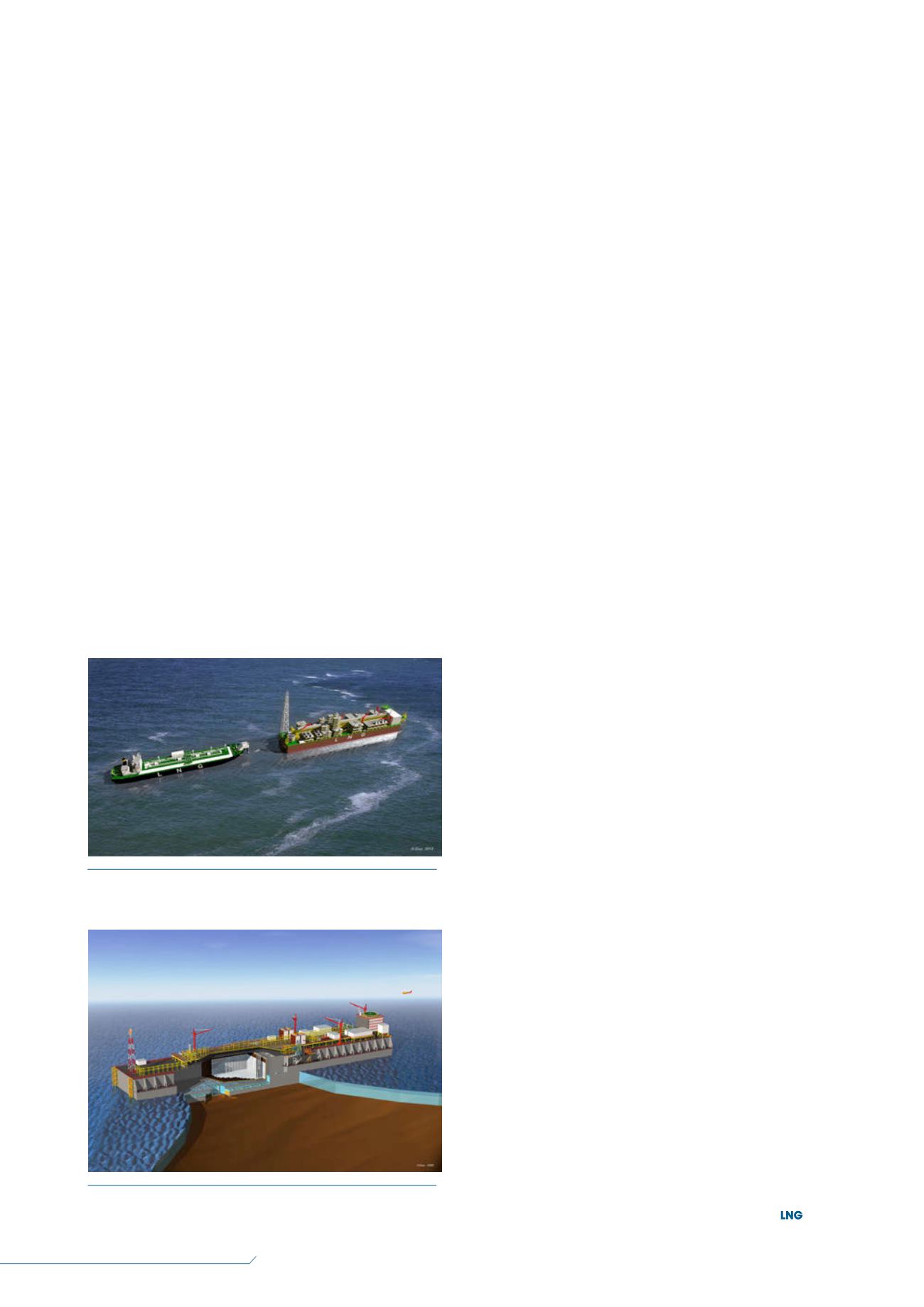

Finally, one of the challenges for producing LNG offshore

in locations where environmental conditions can be harsh,

such as Brazil or Western Australia, is to be able to transfer

the LNG from the floating liquefaction unit to the carrier.

There are intrinsic limitations to the traditional side-by-side

offloading approach (where the LNG carrier is berthed

alongside the FLNG unit), such as the capability of tugs to

operate beyond certain wave heights, the tension induced in

the mooring lines when relative motions between the FLNG

unit and the LNG carrier are too large, and the size of the

loading arms required to deal with such large motions. Since

it is not typically possible for LNG to be safely transferred

from the FLNG unit to the LNG carrier beyond sea states with

significant wave heights of approximately 2 – 2.5 m, Saipem

developed a tandem offloading system where the LNG

carrier is aligned with the FLNG at a distance of

approximately 100 m. The LNG is transferred through a

floating cryogenic flexible pipe developed by Trelleborg in

partnership with Total and Saipem. This configuration

increases the safety of the transfer operation due to the

much larger separation distance and permits unloading in

harsh sea states, making FLNG a viable solution for almost

any location in the world.

Concrete gravity-based

structures and floating

production units

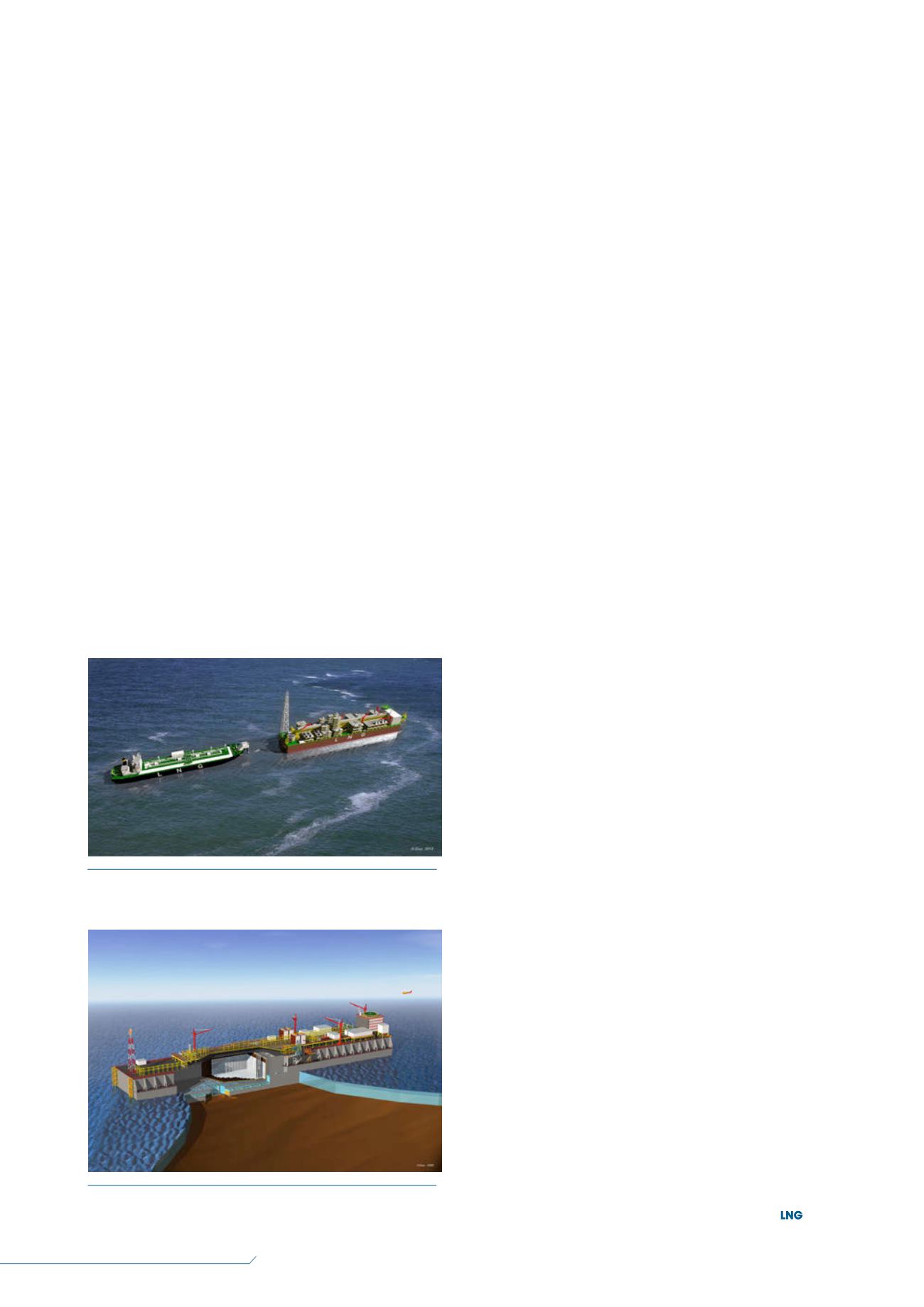

The gravity-based structure (GBS) approach was mostly

promoted in the late 1990s and early 2000s for regasification

plants, in response to a fast-growing LNG market and to the

challenges of obtaining permits for onshore regasification

plants. However, the concept of a concrete GBS can

be just as relevant for liquefaction facilities. The use of

concrete is particularly suited to LNG applications thanks

both to its strong resistance to cryogenic spillage, and

to the advantages provided by a flat wide deck that can

accommodate very heavy topsides.

The LNG GBS is usually designed for shallow waters

(nearshore applications). Saipem has developed several

design options for such facilities: the GBS can be designed as

a long rectangular breakwater for exposed environmental

conditions, or optimised in a more compact prismatic or

cylindrical shape to minimise concrete quantities, depending

on project-specific requirements. The GBS may also offer

significant benefits in terms of local content if the fabrication

of the concrete hull can take place in the final installation

country using a pre-existing or new dedicated graving-dock.

Although concrete hulls have been mostly considered for

GBS applications, floating concrete hulls have also been

considered by the industry over the past few years. A

concrete floating production unit (FPU) barge was built for

the N’Kossa project (Total) by Saipem in 1994, but this was

for oil production at the time. The competitiveness of a

complete FLNG unit built with a concrete hull compared to a

steel hull FLNG may be questioned, but a scheme with an

LNG concrete FPU carrying liquefaction topsides combined

with a converted LNG carrier floating storage and offloading

(FSO) unit could benefit from the significantly lower cost of

the hulls and become an interesting option for some sites

and countries.

Conclusion

Over the past 20 years, offshore LNG has become a reality

thanks to the adaptation of LNG technologies to offshore

constraints and the development of specific enabling

technologies that have now reached maturity. Saipem has

played a major part in the various developments described

in this article through a number of collaborations with major

oil and gas companies and key suppliers. Today, the new

challenge for the LNG industry is to make those technologies

viable in the context of a low oil price environment.

Figure 4.

Breakwater-shaped regasification gravity-based

structure (GBS) with sectional view.

Figure 3.

LNG tandem offloading configuration with floating

hoses.