58

LNG

INDUSTRY

SEPTEMBER

2016

land-based facilities, which are often located in areas of

environmental interest, or far away from existing

infrastructure. This new technology can present unique

technical demands, while storing and handling LNG is

challenging for plant engineers in relation to infrastructure.

Cooled to and stored at -162°C, LNG requires specially

designed and engineered equipment to perform safely

under demanding conditions, which, combined with the

substantial energy potential and flammability of the gas,

generates significant potential for hazardous events. These

factors have led to an industry-wide focus on safety and

standards.

The need for safety

There are many aspects to plant safety. Installations need

to be robust and well-maintained not only to maximise

uptime and process efficiency, but also to ensure

safe and reliable operations. While numerous safety

devices are required for both land-based and offshore

liquefaction, one of the most critical areas is valve design

and application. Regardless of the type of LNG facility,

reliable and high performance safety instrumented systems

(SISs), control systems and safety valves are designed

to continually monitor the status of the processes. They

react instantaneously to any mechanical, electrical or

operational failure, which may lead to a critical process

upset or overpressure event, resulting in the release of

flammable and toxic process media. This safeguards plant

personnel, plant assets and the surrounding communities

and environment from damage.

Valve solutions

Pilot operated pressure relief devices

Mandatory by international code for the protection of

pressure vessels and pipelines, pressure relief valves (PRVs)

are the last line of defence when it comes to plant safety.

Selection of the correct PRV type ensures that the valve can

operate under extreme operating temperatures to provide

optimum safety in the LNG process. It also minimises

environmental impact from seat leakage. As the final device

designed to prevent failure during overpressure conditions,

PRVs must offer complete reliability that they will open at a

predetermined set pressure, allow a specific capacity flow

within the allowable overpressure limit, and close once

normal conditions have been restored. The design of these

valves must withstand corrosive process media, enable

critical protection against overpressure and avoid the risk of

explosion.

PRV manufacturing has evolved over the years to adapt

to the changing requirements of LNG applications.

Considerations such as flow capacity, footprint, durability,

and opening and closing performance must be taken into

account, all the while being able to tolerate increasing

operational and output demands. Pilot operated PRVs on

LNG carriers and land-based LNG storage tanks are vital to

process safety due to their compliance with high seat

tightness standards (zero leakage as per API RP 527). This

improves further as the operating pressure reaches its set

pressure point. The full opening capability of PRVs and the

large surface area of the pilot diaphragm ensure

instantaneous and accurate pressure relief. Further

advantages, such as high flow capacity, optimised flow/size

ratio and minimised maintenance requirements, deliver

additional key benefits to engineers.

Safety instrumented systems

Designed to protect personnel, equipment and the

environment by mitigating the likelihood and severity

of potential risks, SISs also constitute a critical factor in

LNG applications. Comprising sensors, a logic solver and

emergency shutdown valves (ESDVs), the SIS serves

to take the process to a safe state when predetermined

safety configurations are violated. Emergency shutdown

(ESD) systems and high integrity pressure protection

systems (HIPPSs) are two subsystems of SISs, with the

former providing safe and reliable shutdown of a process

and HIPPS designed to prevent overpressurisation. Each

consists of an automated ESDV package, known as the final

control element due to its role as the ‘last line of defence’

in the event of an emergency situation. This component

is required to fail close or open in response to potentially

hazardous process conditions and is in direct contact with

the process media, so is considered the weakest link in the

system. It also contributes more than 50% of the calculated

risk reduction factor (RRF). Selection and design of the

ESDV, therefore, require special attention to ensure that it is

suited to the operational requirements of the ESD system.

A critical factor to take into consideration is compliance

with safety standards. Each component of the SIS must

meet the safety integrity level (SIL) required to satisfy plant

safety requirement specifications. Operating companies can

substantially increase their SIL loop rating if they adopt a

rigorous testing and maintenance programme on their

safety valves. By combining partial stroke testing (PST) of

valves with more frequent inspection, companies can

achieve a higher SIL rating without incurring the costs

associated with additional hardware.

An important step to ensure that an ESDV will perform

as intended when needed, PST has long been used to

deliver numerous advantages in addition to an improved

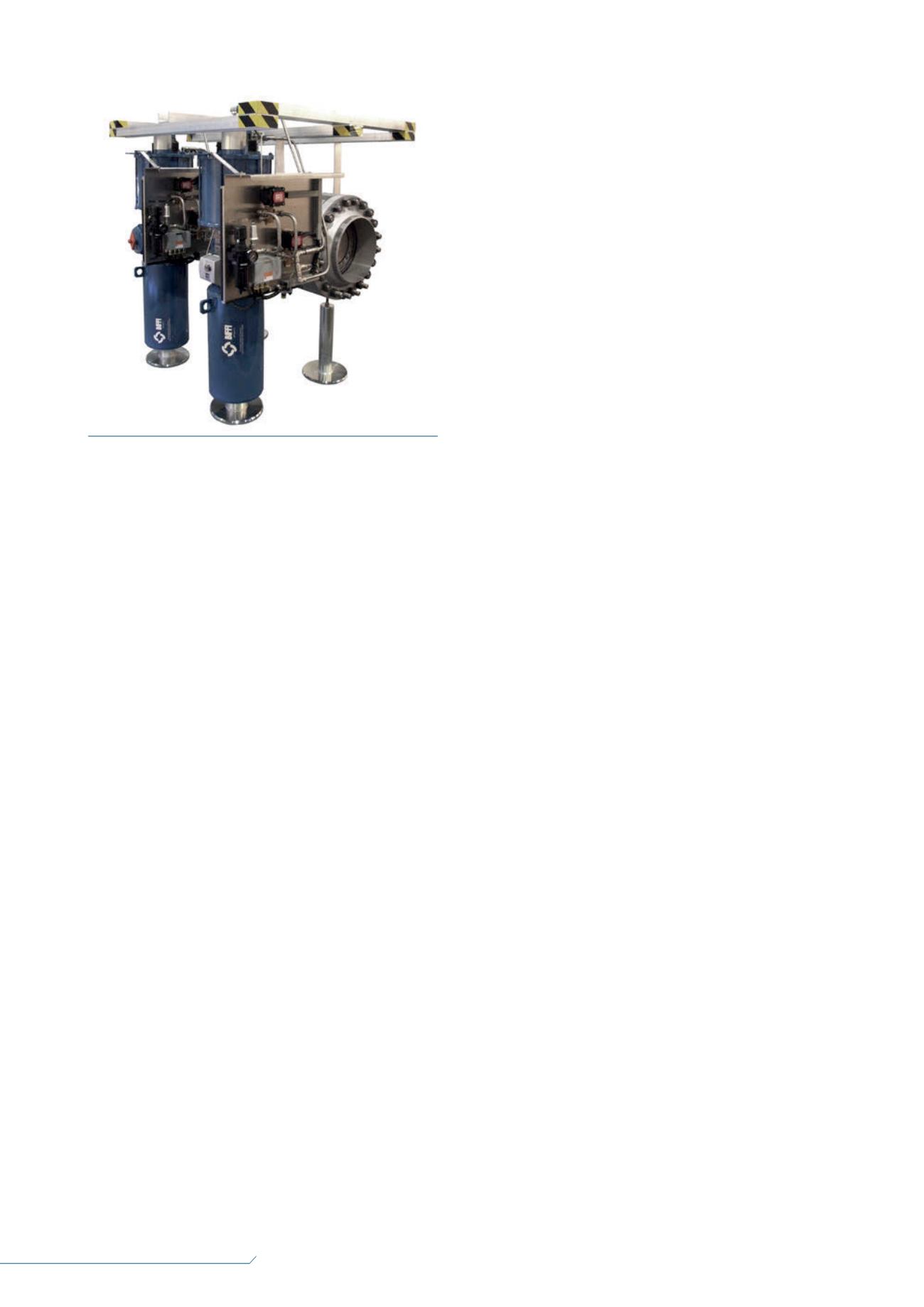

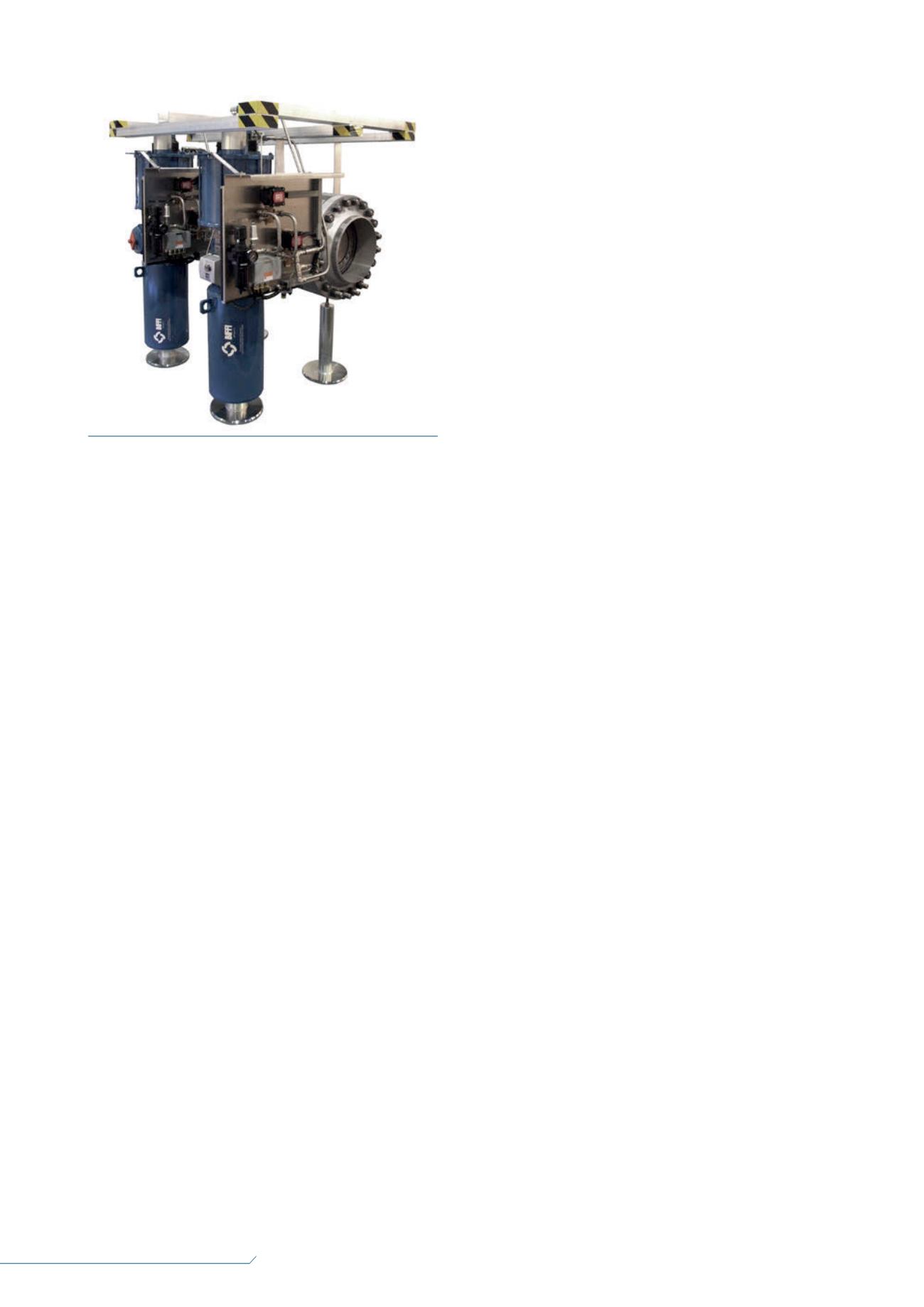

Figure 1.

Pentair Valves & Controls’ safety instrumented

system (SIS) package.