60

LNG

INDUSTRY

SEPTEMBER

2016

SIL rating. These include access to predictive maintenance

data, reduced need for valve bypasses, extension of full

stroke testing intervals, and availability of valves to

respond to process demands during test periods. The

latest developments enable PST to be carried out with

limited human intervention in a semi-automatic way

through the use of smart microprocessor-based devices.

This advanced monitoring and control technology for

ESDVs has made PST more effective and easier to

implement, helping to achieve improved integrity and

safety of processes.

When designing HIPPS and ESD systems, the complete

lifecycle should be considered from front end engineering

design (FEED) through to maintenance, commissioning and

service. Additional optimisation can be achieved through a

simplified control scheme, which reduces the need for

human dependency. It can be utilised to extend proof test

intervals and, when combined with effective diagnostics,

PST allows customers to move from reactive to predictive

maintenance. Such optimisation strategies are essential to

develop a system that not only meets the requirements of

high integrity safety systems, but which also allows for the

responsible management of CAPEX and OPEX.

Triple offset technology

Triple offset valves (TOVs) also play a key role in LNG

applications and are integral to the safe operation of critical

functions. Effective design and excellent performance

characteristics enable the valve to handle the demands

of the liquefaction process. For example, the valves’

non-rubbing metal-to-metal seating design provides zero

leakage shut-off performance and complete fire safety.

This enhances reliability and can reduce overall equipment

footprint and cost of ownership. Different types of TOVs

offer additional benefits. Top entry TOVs, for example, are

designed to allow inline maintenance, enabling users to

access individual valve parts in total safety.

Certification considerations

FLNG comprises additional risks, requiring further

consideration with regard to safety and standards.

Understanding the risks and how best to mitigate them

will help prevent the potential for disasters and provide

guidance on how to ensure optimum safety on a vessel.

Certification bodies play a key role here, validating that

critical equipment meets the required safety standards.

With a focus on technical assessment advisory and risk

management, DNV GL is an example of an international

classification and certification association that may impose

overarching requirements for certain valves in FLNG.

Manufacturers must submit their valves for a formal design

review, which comprises a design verification report, survey

during manufacture, and a data book review. Following this,

they have two options: type approval or a product

certification, the latter of which is hull, project or application

specific. Valve types covered can include PRVs and ESDVs,

as well as cryogenic, hull and boiler-related valves. This

rigorous process is performed to ensure that the

components fulfil their specific requirements, helping to

guide the development of the design phase and ensure

maximum safety.

Partnership

Ensuring that plants are safe and equipment complies

with SIL requirements and other standards is imperative.

Specification and installation of valves, actuators and

controls can be made more efficient by working with

one manufacturer, which provides safety elements

and solutions designed to withstand the demanding

conditions of the liquefaction process. A company acting

as one single point of contact from assembly through to

aftermarket support helps operators mitigate risk and

optimise their value chain. In addition to robust, high quality

products with proven performance in LNG applications,

operators seek a complete package warranty and sole

source accountability, which original

equipment manufacturers (OEMs) are

able to provide.

Summary

An industry where safety is a must,

LNG operations – whether land-based

or offshore – cannot be considered

lightly. While plant operators demand

efficiency, durability and minimised cost

and maintenance from their process

equipment, a key focus is placed on

protecting people and assets, and the

avoidance of operational downtime.

Manufacturers of critical components

must, therefore, keep safety in mind as

they craft solutions for this challenging

environment. Optimised valve

technology created in line with industry

evolution and tailored to specific

applications of the LNG process can

meet the needs of plant designers and

operators.

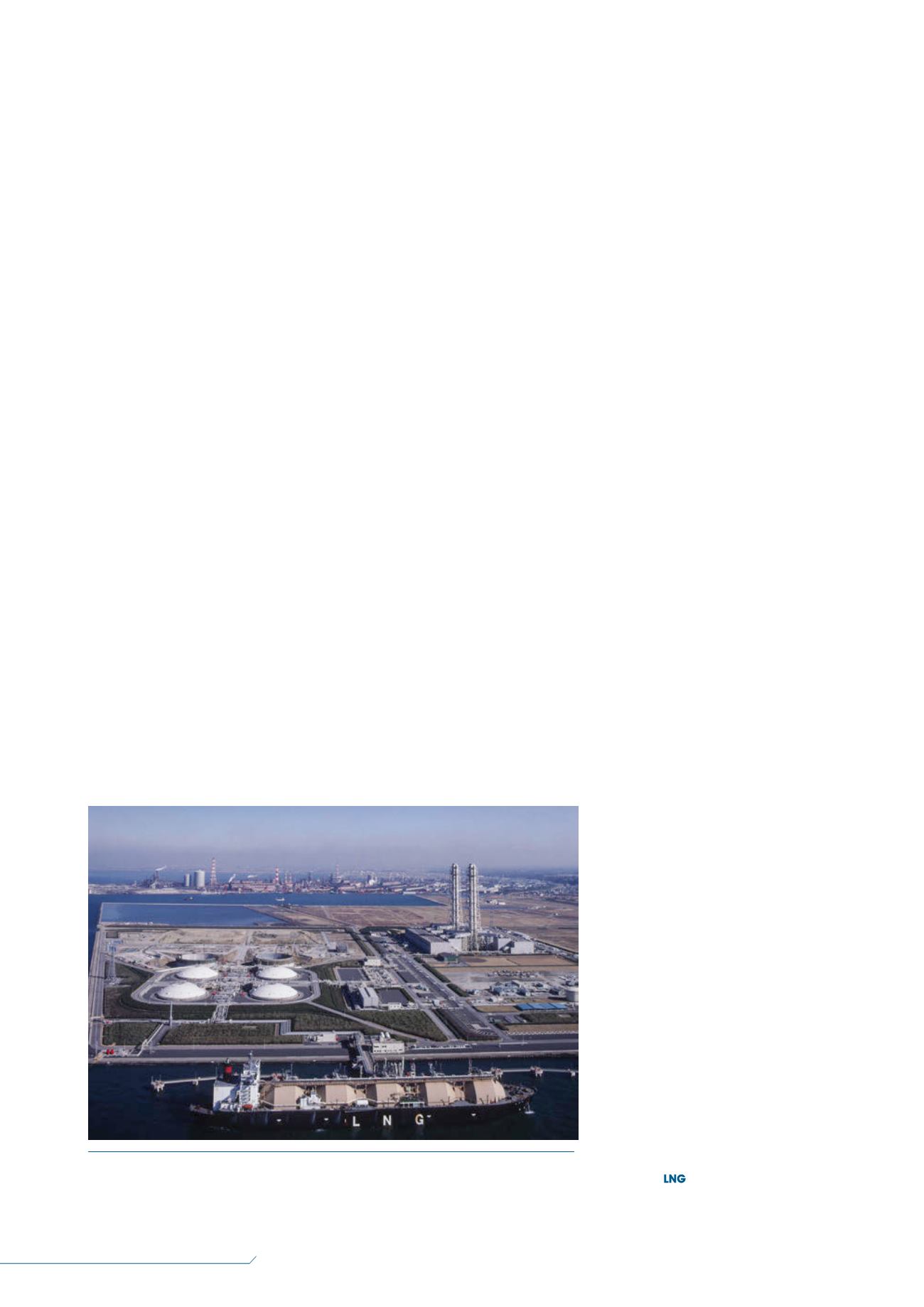

Figure 2.

Effective valve design and application is critical for safe and reliable

operations.