50

LNG

INDUSTRY

SEPTEMBER

2016

Deepwater intake solution

The liquefaction process requires large volumes of cooling

water. As a reference point, Shell’s

Prelude

FLNG facility

offshore Australia is designed for a cooling water intake

capacity of 50 000 m

3

/hr.

1

Prelude

will be installed at 250 m

water depth, with surface temperatures in the range of 25°C

and water intake located 150 m below the surface.

Reduced cooling water temperature gives an

approximately 1% increase in liquefaction process capacity per

degree Celsius temperature reduction. If intake air to gas

turbine drivers is also cooled by cold seawater, then the turbine

power output can be increased by approximately 1.5% per

degree Celsius air temperature reduction. Combining these two

effects, LNG production can typically be increased by 20% for a

tropical deepwater FLNG unit using the same gas turbine

drivers.

2

For a 2500 mwater depth case, Aker Solutions and Statoil

have conceptually designed an FLNG water intake system that

fetches cooling water from a water depth of 500 – 700 m. With

this system, there is the potential to reduce the cooling water

temperature by 15 – 20°C and increase the process efficiency

correspondingly. The Statoil FLNG case includes a bow turret

moored ship with a length of more than 400 m and an LNG

capacity of 3 – 3.5 million tpy, located in ~25°C surface

temperatures. The estimated cooling water requirement is

35 000 m

3

/hr taken from 500 mwater depths. This water

intake volume requirement corresponds to 700 full size

semi-trailers with water per hour – i.e. one semi-trailer every

5 sec. – necessitating large capacity suction pipes. A concept

with two single mounted steel risers with a diameter of up to

64 in. minimises implications on the ship design and process

layout.

System description

The water intake risers are mounted in sea chests aft on the

FLNG vessel – one on the starboard side and one on the port

side.

The material selected is carbon steel, with a minimum yield

strength of 415 MPa. The 64 in. riser pipes have a nominal wall

thickness of 20 mm. The outside steel surfaces are corrosion

protected both by anodes and coating, while the internal

surfaces are protected by a thermal sprayed aluminium coating.

The water intake risers are assembled from 24 m long

standard joints with flanged connections. One 500 m long

water intake riser weighs approximately 515 t in air and 395 t

when installed and submerged in seawater.

A pressure head loss of 4.5 m is assessed for 35 000 m

3

/hr

of cold seawater flowing in two 64 in. risers where the internal

diameter is reduced to 40 in. locally at hang-off.

Six dry mounted pumps (including one spare) installed in

pump rooms are the base case. Each pump has a capacity of

7000 m

3

/hr. Alternatively, submerged caisson pumps can be

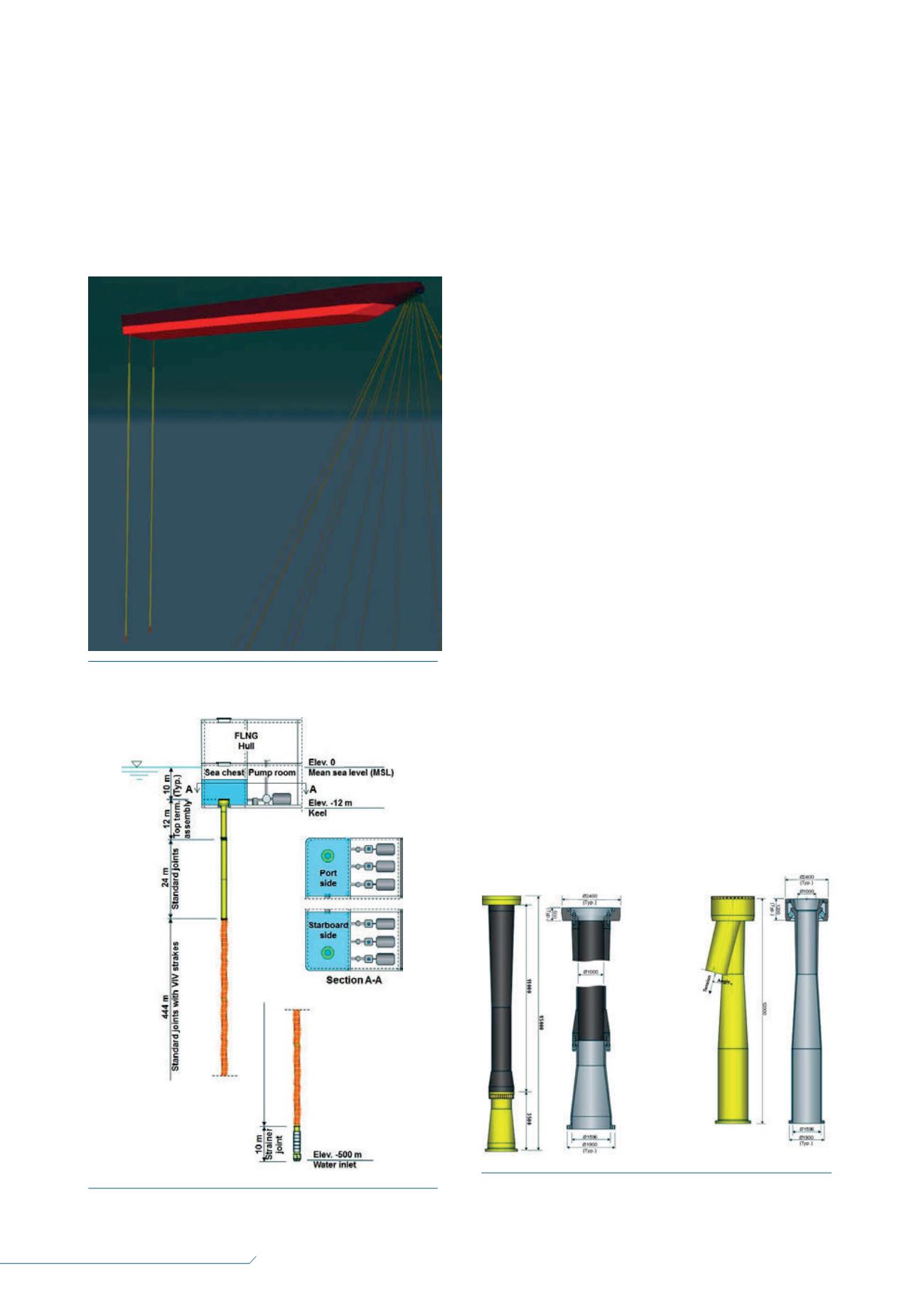

Figure 1.

Floating LNG (FLNG) vessel with two 500 m deep

water intake risers.

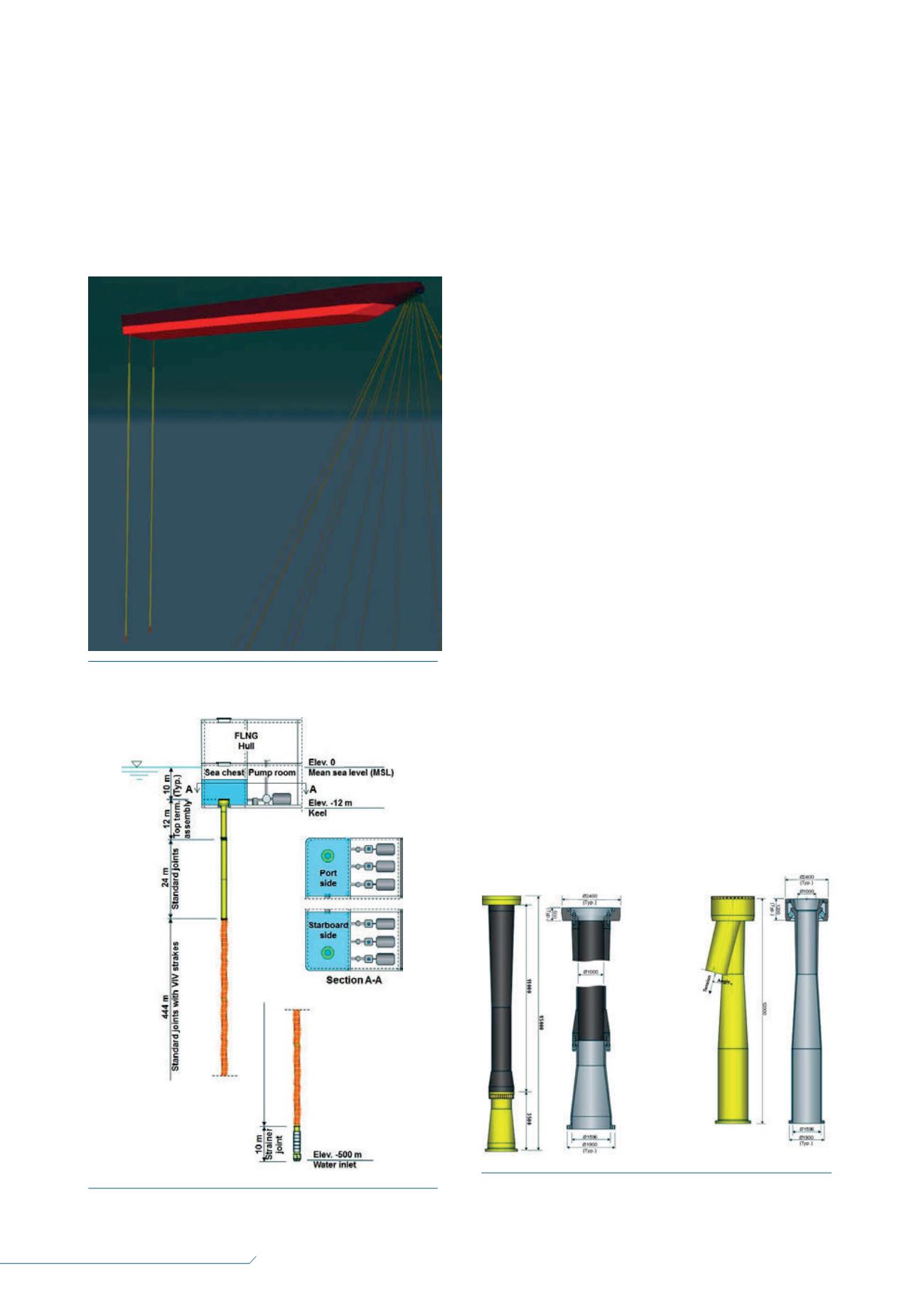

Figure 2.

Aker Solutions’ FLNG water intake concept for

fetching 35 000 m

3

/hr of seawater from 500 m water depth.

Figure 3.

Alternative flexible hang-off assemblies with locally

reduced diameter. Reinforced flexible hose (left) and flexible

bearing element (right).