52

LNG

INDUSTRY

SEPTEMBER

2016

can be welded in full length onshore, transported offshore,

upended and connected to the FLNG hull.

Installation from the FLNG vessel is facilitated by

connecting the flanged riser joints while the riser is supported

in a spider at ship deck. The lifting and lowering height will be

dictated by the selected riser joint length. Heading control is

assumed for the riser installation, either by using the vessel

heading control system (if applicable), or by connecting tugs

to the stern of the vessel.

The plan is to install the risers outside of the monsoon

season to avoid strong currents and severe wave conditions.

Installation in the monsoon season remains feasible, but

should be avoided due to increased risk of stop in operation

and waiting on weather.

If forecasted or measured environmental conditions

exceed a specified level, the installation will enter into a safe

condition within 3 hours. In the safe condition, the partly

assembled riser will survive an event with return period of

10 years. Heading control is not required for the safe condition.

The described installation method is based on established

industry solutions and technology.

Preventing marine growth

Cooling water intake systems make use of hypochlorite

to prevent marine growth in water intake risers, sea chest

compartments, seawater pumps, seawater piping and heat

exchangers for gas cooling. Hypochlorite can be injected into the

seawater at the 500mdeep intake, or at the inlet to the sea chest

compartment. However, marine growth is dependent on solar

light (a considerable reduction inmarine life is observed close to

the solar light limit). Deeper intake risers will be environmentally

beneficial due to the substantially reduced need for use of

hypochlorite.

Conclusion

Aker Solutions’ new deep cooling water intake solution for FLNG

can help to increase the efficiency of offshore LNG processing.

Reducing cooling water temperature by 15 – 20°C has significant

efficiency gains in a large FLNG development. The efficiency

improvements are complemented by a design that eliminates the

need for separate installation vessels, reducing field development

costs. Use of deepwater intake risers also decreases the need

for hypochlorite use in operation, adding an environmental

benefit. The concept is based on extending the use of well-known

technology. While some further technology qualification is

necessary, the company’s deep cooling water intake solution is

ready for front end engineering and design (FEED) application on

relevant FLNG developments.

References

1. PEK, B. and VAN DER VELDE, H., ‘A High Capacity

Floating LNG Design’, 17

th

International Conference &

Exhibition on Liquefied Natural Gas, Houston, Texas, US,

(April 2013), pp. 16

–

19.

2. NEERAAS, B. O. and PETTERSEN, J., ‘Technical Innovation

for Floating LNG’, 3

rd

Trondheim Gas Technology

Conference, (4

–

5 June 2014).

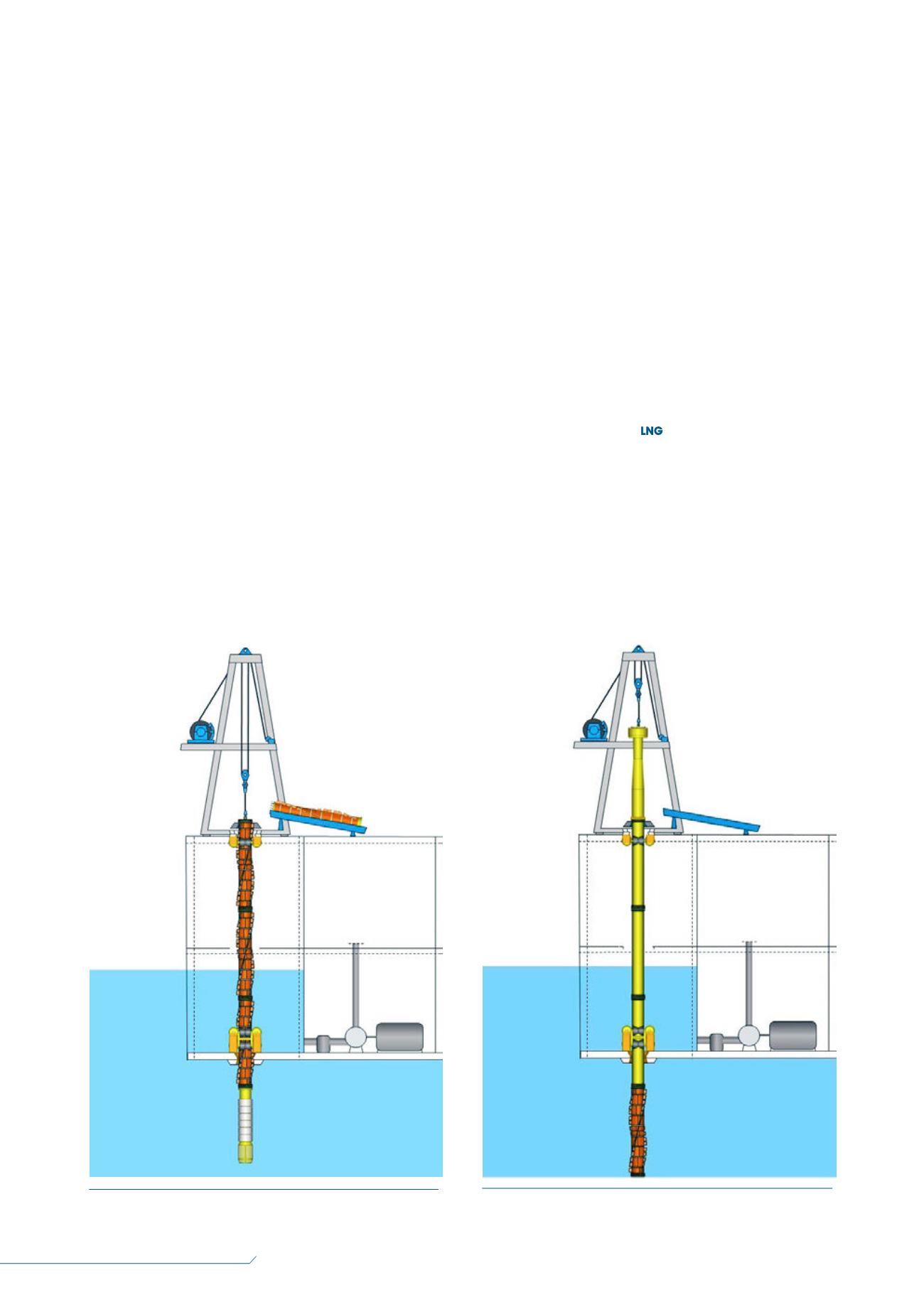

Figure 5.

Riser installation – top end with flexible hang-off

assembly.

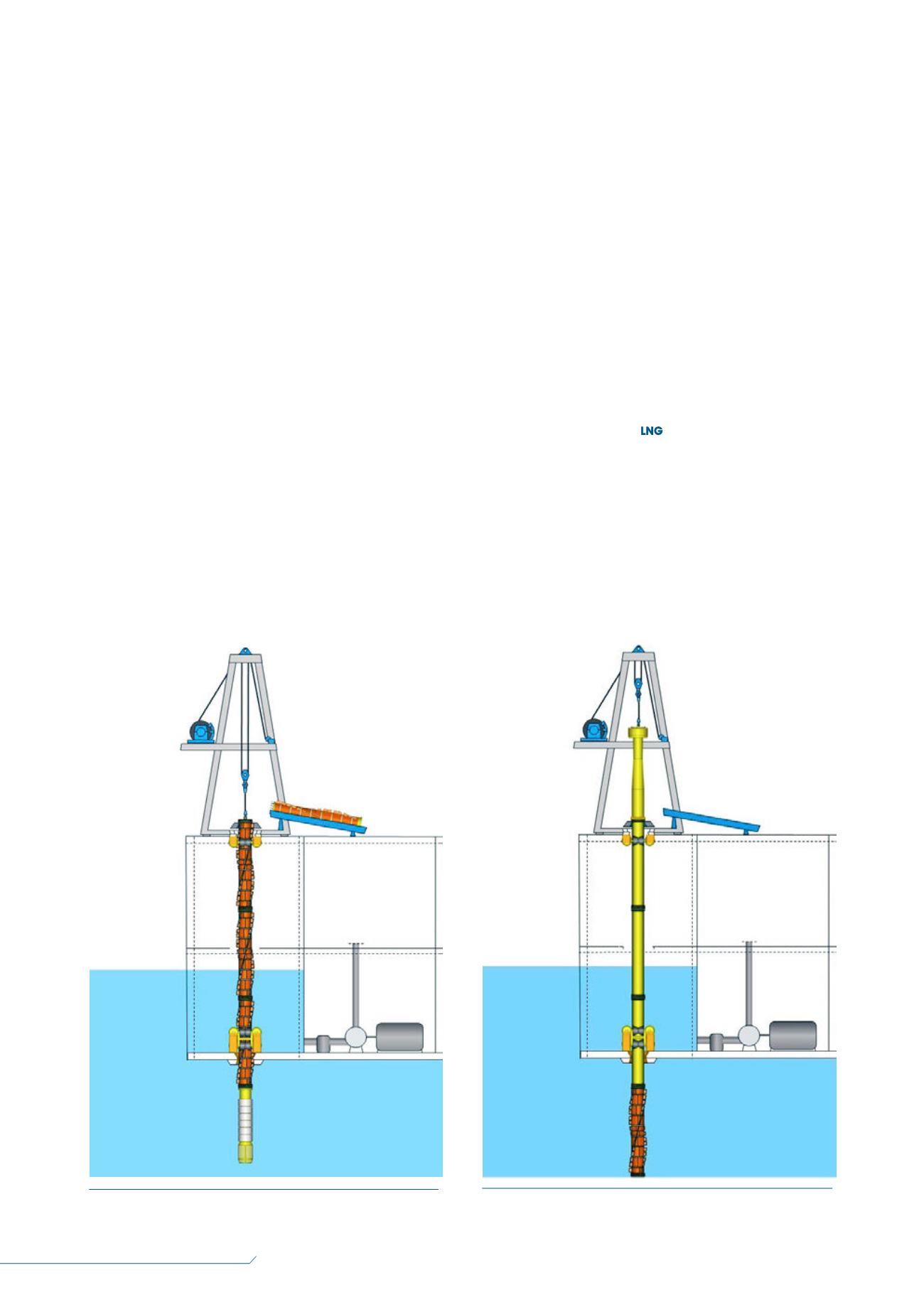

Figure 4.

Riser installation – mounting of standard joints with

vortex induced vibration (VIV) strakes.